Ultrasonic micro mixer with millisecond mixing performance

A technology of micro-mixer and mixing performance, which is applied in the direction of mixers, shaking/oscillating/vibrating mixers, chemical instruments and methods, etc. It can solve the problems of easy blockage of channels and inability to achieve millisecond-level mixing, etc., and achieve continuous preparation. The effect of clogging risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

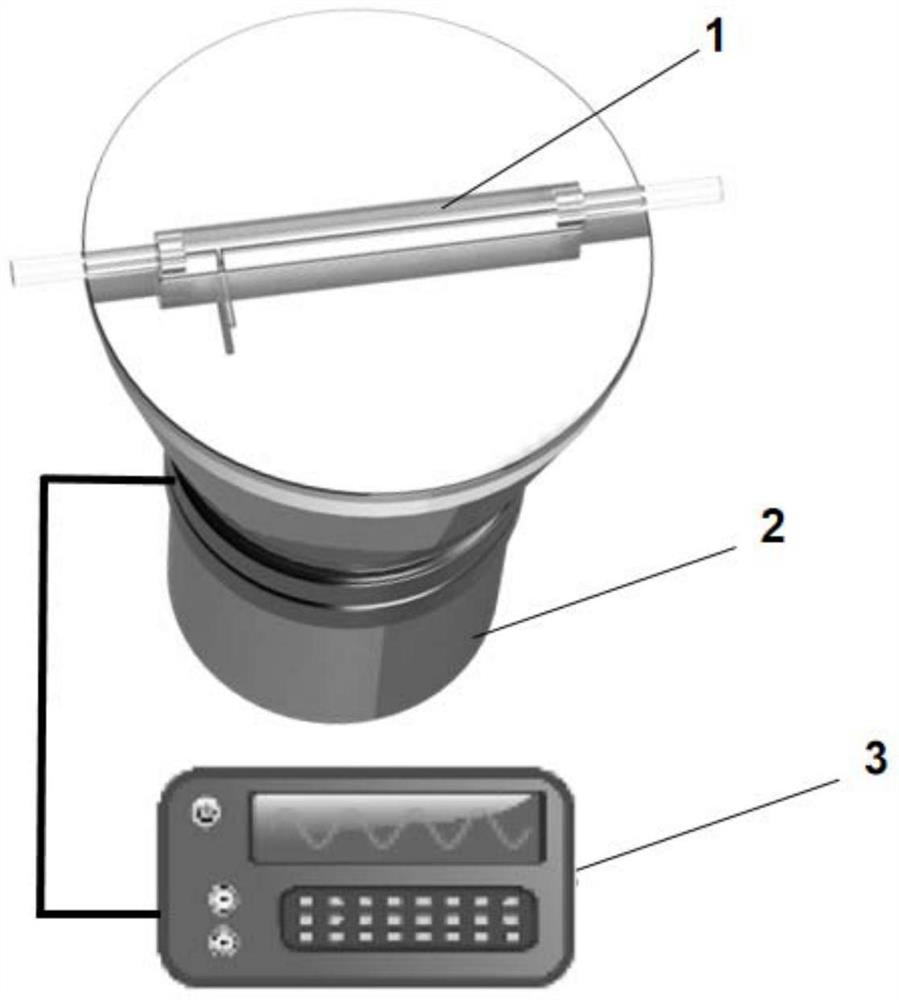

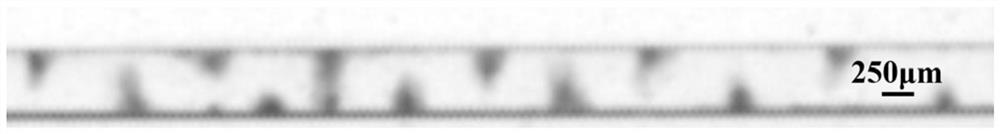

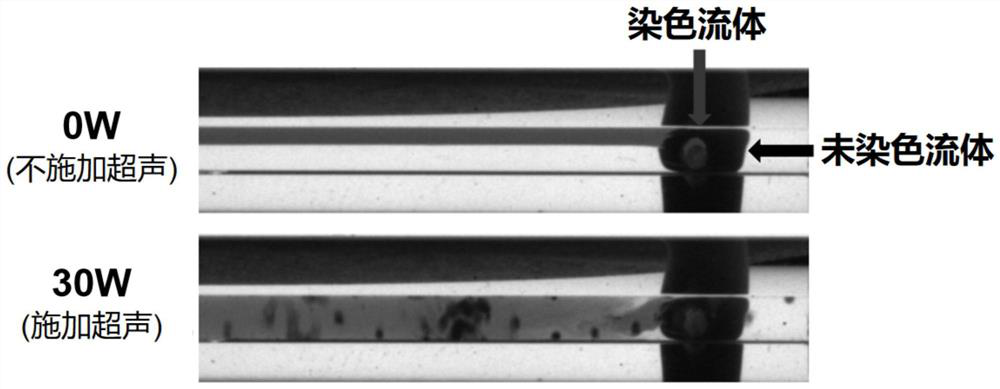

[0028] This embodiment is an ultrasonic micro-mixer with an operating frequency of the ultrasonic transducer 2 of 20 kHz and a hydraulic diameter of a channel of the micro-mixer 1 of 1 mm. The ultrasonic micromixer is as figure 1 As shown, it consists of a micro mixer 1, an ultrasonic transducer 2, and an ultrasonic generator 3. The working frequency of the ultrasonic transducer 2 corresponds to the wavelength of the sound wave in the air, which is 17 times the hydraulic diameter of the channel of the micro-mixer 1. The hydraulic diameter of the micro-mixer 1 channel is 1 mm, the channel section is circular, and the material is glass. The working frequency of the ultrasonic transducer 2 is 20 kHz, and the working power is 5, 10, 20, and 30W, respectively. The ultrasonic transducer 2 is a Langevin sandwich ultrasonic transducer 2 (Baoding Zhengjie Electronics ZFHN-020). The micro-mixer 1 and the ultrasonic transducer 2 are directly coupled and rigidly connected, and the direc...

Embodiment 2

[0033] This embodiment is an ultrasonic micro-mixer with an operating frequency of the ultrasonic transducer 2 of 20 kHz and a hydraulic diameter of a channel of the micro-mixer 1 of 0.5 mm. The ultrasonic micromixer is as figure 1 As shown, it consists of a micro mixer 1, an ultrasonic transducer 2, and an ultrasonic generator 3. The working frequency of the ultrasonic transducer 2 corresponds to the wavelength of the sound wave in the air, which is 34 times the hydraulic diameter of the channel of the micro-mixer 1. The hydraulic diameter of the channel of the micro-mixer 1 is 0.5mm, the channel section is circular, and the material is glass. The working frequency of the ultrasonic transducer 2 is 20kHz, and the working power is 1, 5, 10, 20, 50, 100, 200, 400 respectively. , 500W. The ultrasonic transducer 2 is a Langevin sandwich ultrasonic transducer 2 (Baoding Zhengjie Electronics ZFHN-020). The micro-mixer 1 and the ultrasonic transducer 2 are directly coupled and ri...

Embodiment 3

[0035] This embodiment is an ultrasonic micro-mixer with an operating frequency of the ultrasonic transducer 2 of 20 kHz and a hydraulic diameter of a channel of the micro-mixer 1 of 0.25 mm. The ultrasonic micromixer is as figure 1 As shown, it consists of a micro mixer 1, an ultrasonic transducer 2, and an ultrasonic generator 3. The working frequency of the ultrasonic transducer 2 corresponds to the wavelength of the sound wave in the air, which is 68 times the hydraulic diameter of the channel of the micro-mixer 1. The hydraulic diameter of the channel of the micro-mixer 1 is 0.25mm, the channel section is circular, the material is glass, the working frequency of the ultrasonic transducer 2 is 20kHz, and the working power is 1, 5, 10, 20, 50, 100, 200, 400 , 500W. The ultrasonic transducer 2 is a Langevin sandwich ultrasonic transducer 2 (Baoding Zhengjie Electronics ZFHN-020). The micro-mixer 1 and the ultrasonic transducer 2 are directly coupled and rigidly connected,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com