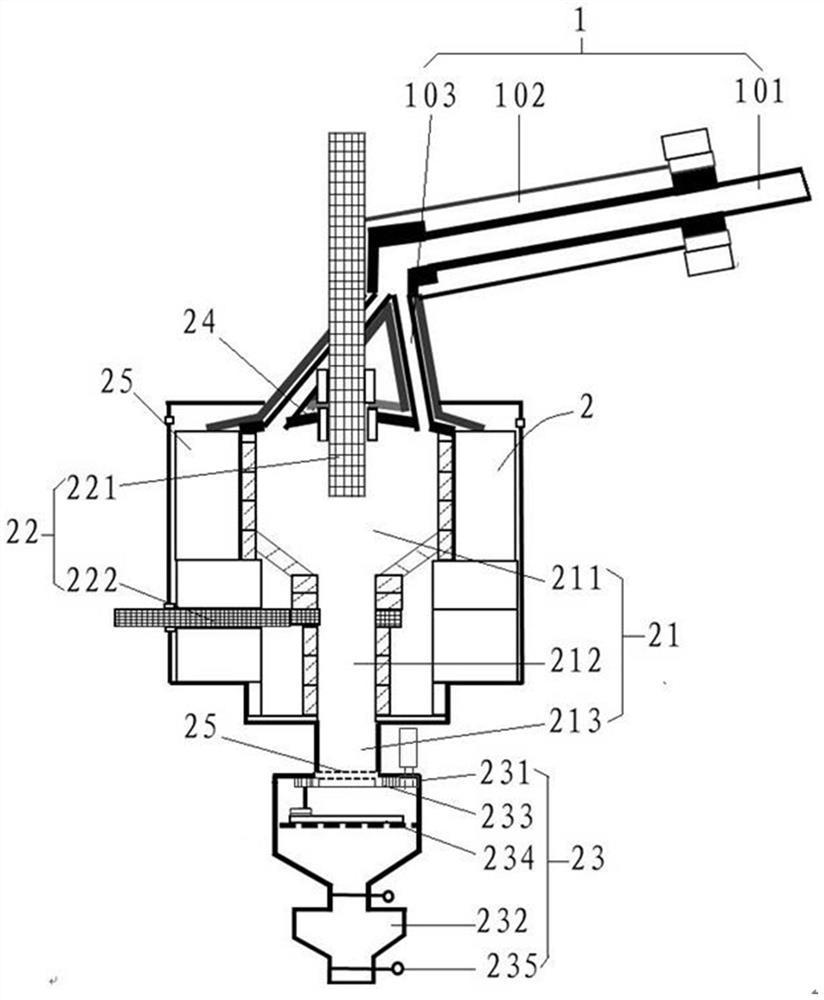

Continuous electrothermal furnace and method for resourceful treatment of aluminum electrolysis carbon electrode waste

A carbon electrode and electric heating furnace technology, applied in the field of aluminum electrolysis waste recycling, to ensure safety, avoid cyanide pollution, and avoid enrichment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

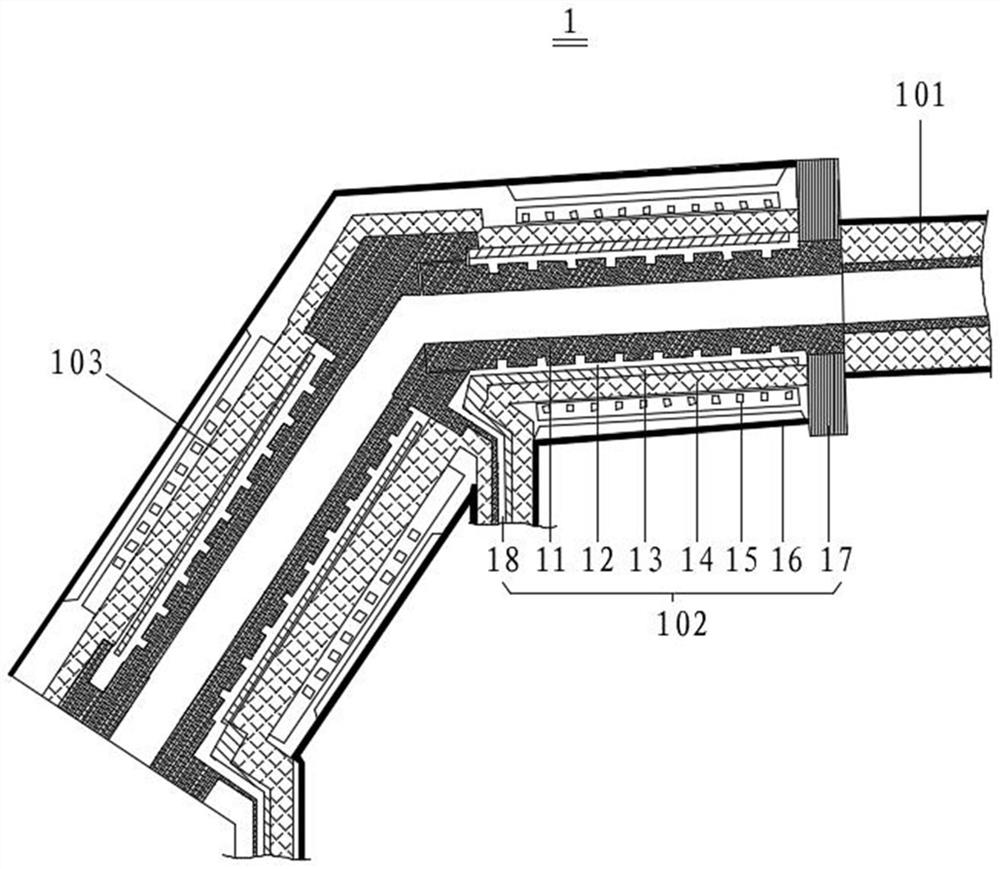

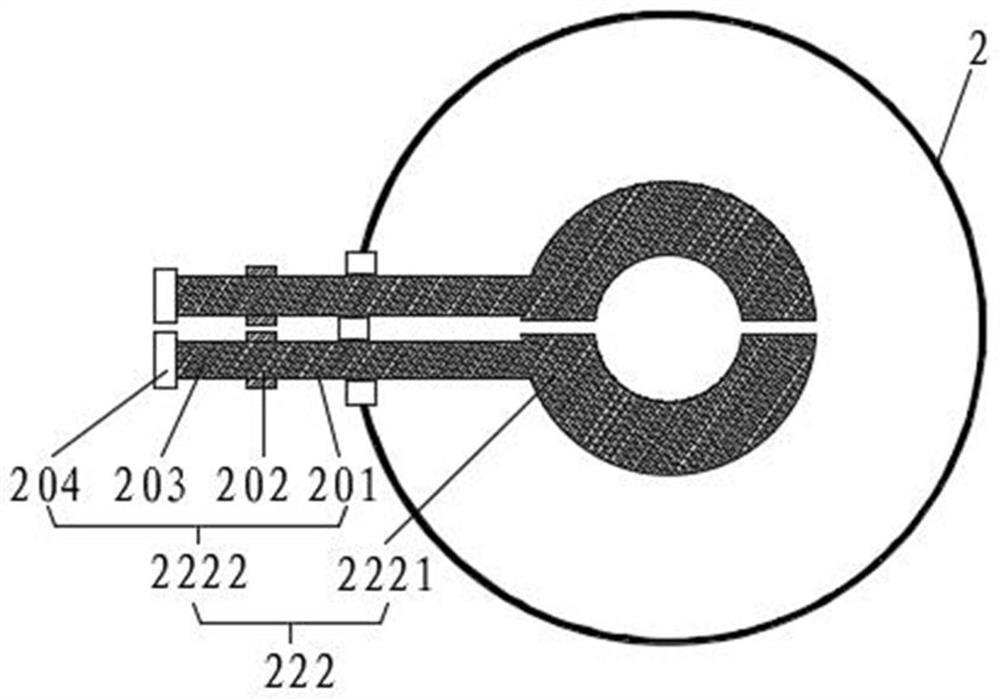

Method used

Image

Examples

Embodiment 1

[0107] The carbon electrode waste selected in this embodiment is the spent cathode carbon block, and the following treatment process is adopted.

[0108] (1) Use a jaw crusher to crush the waste cathode carbon blocks into carbon blocks with a particle size of 0-150mm, sort out the mixed aluminum flakes through a sorting machine or manually, remove the mixed scrap iron through an iron remover, and then use a hoist The processed waste cathode carbon blocks are transported to the raw material bin on the top of the electric furnace, and the raw material bin is fed to the waste heat preheating section of the preheating separation channel.

[0109] (2) In the waste heat preheating section, dry the water vapor in the waste cathode carbon block at a temperature from room temperature to 450°C to prevent water from reacting with hot carbon to form water gas. The reaction equation is C+H 2 O=CO+H 2 ; Digest trace cyanide 4NaCN+5O 2 = 2Na 2 O+4CO 2 +2N 2 ; Thermal expansion drives ou...

Embodiment 2

[0120] The carbon electrode waste selected in this embodiment is anode carbon slag flotation carbon powder, and the following treatment process is adopted.

[0121] (1) Transport the anode carbon slag flotation carbon powder to the raw material warehouse on the top of the electric furnace, and the anode carbon slag flotation carbon powder in the raw material warehouse is transported to the waste heat preheating section after being metered. In the residual heat preheating section, the water vapor in the anode carbon slag flotation carbon powder is dried at a temperature from room temperature to 450 ° C to prevent water from reacting with hot carbon to form water gas. The reaction equation is C+H 2 O=CO+H 2 ; Digest trace cyanide 4NaCN+5O 2 = 2Na 2 O+4CO 2 +2N 2 ; Thermal expansion drives out O 2 ; Eliminate carbon monoxide 2C+O generated by incomplete combustion of carbon 2 =2CO; Then, use the residual heat of the exhaust gas from the electric furnace to continue to prehe...

Embodiment 3

[0127] The carbon electrode waste selected in this embodiment is anode carbon slag, and the following treatment process is adopted.

[0128] (1) Use a jaw crusher to crush the anode carbon slag into carbon blocks with a particle size of 0-100mm. After removing iron from the aluminum sheet, use a hoist to transport the processed carbon blocks to the raw materials on the top of the electric furnace warehouse, and the material is fed from the raw material warehouse to the waste heat preheating section of the preheating separation channel.

[0129] (2) In the waste heat preheating section, dry the water vapor in the anode carbon slag at room temperature to 450°C to prevent water from reacting with hot carbon to form water gas. The reaction equation is C+H 2 O=CO+H 2 ; Digest trace cyanide 4NaCN+5O 2 = 2Na 2 O+4CO 2 +2N 2 ; Thermal expansion drives out O 2 ; Eliminate carbon monoxide 2C+O generated by incomplete combustion of carbon 2 =2CO; Then, the anode carbon slag is pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com