3D digital decoration method and device based on water-based UV curing ink

An ink and water-based technology, used in typewriters, printing and other directions, can solve the problems of high ink toxicity, high use cost and high manufacturing price, achieve high-speed 3D printing, realize 3D printing, and increase the effect of ink output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

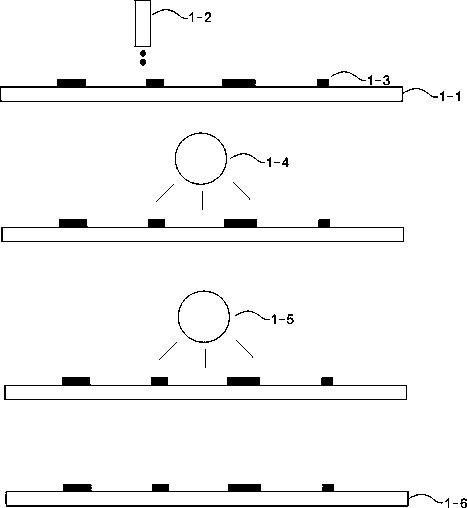

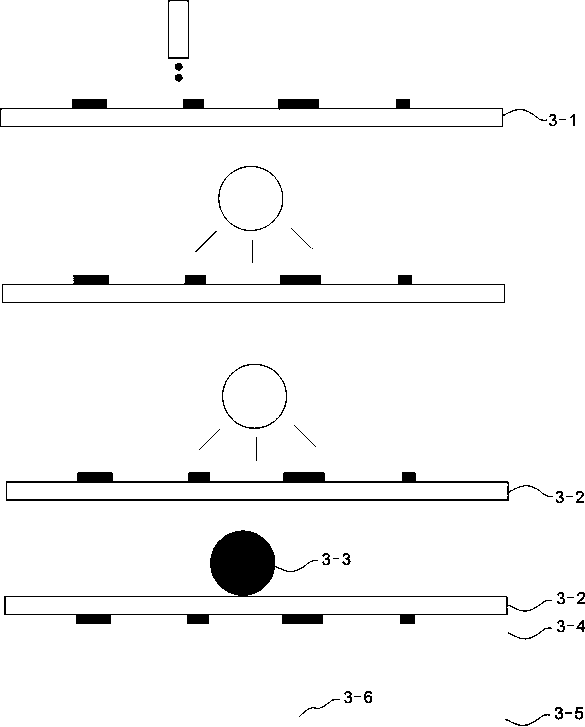

[0068] Embodiment I 3D partial UV glazing

[0069] Install the jetting part (customized) on the XY control platform of the Yitu CA24 cutting plotter, and fill it with water-based UV curing ink. The parameters of the ink are: solid content 40%, viscosity 60mpas, and surface tension 45 dyn / cm. Print the water-based UV curing ink on the surface of the white cardboard (300g) substrate, then enter the drying module for heat drying for 1min, and then enter the curing module (1000w mercury lamp) for UV curing for 5s to complete 3D partial UV glazing.

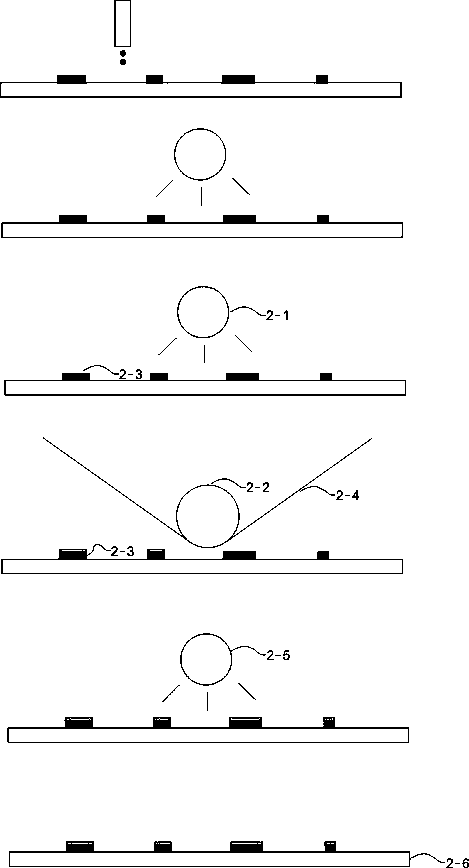

[0070] Example II 3D Hot Stamping

[0071] Install the injection parts (customized) on the XY control platform of Han's Yueming Laser CMA6040 laser cutting machine, and pour water-based UV curing ink. The parameters of the ink are: solid content 50%, viscosity 100mpas, surface tension value 50 dyn / cm . Print the water-based UV curing ink on the surface of the coated paper (300g) substrate, then enter the drying module for heat drying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com