Photocatalysis-plant cooperated water purifying method for pisciculture water

A technology of photocatalysis and photocatalytic materials, which is applied in the field of continuous water purification technology, can solve the problems of affecting light and flow, high operating costs, difficult separation and recovery, etc., and achieves strong applicability, small shading effect, and eco-friendly environment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A photocatalysis-plant synergistic water purification method for fish farming water, the process flow is as follows:

[0016] 1) The submersible pump is placed in the fish farming water body, and the outlet of the pump is connected to the inlet valve of the filter tank 1 through a pipeline. The sewage in the fish pond is pumped to the filter tank by the submersible pump; the solid phase impurities are filtered by the foam sponge 2 in the sewage in the filter tank; the solid phase impurities retained after filtering are regularly discharged through the sewage valve.

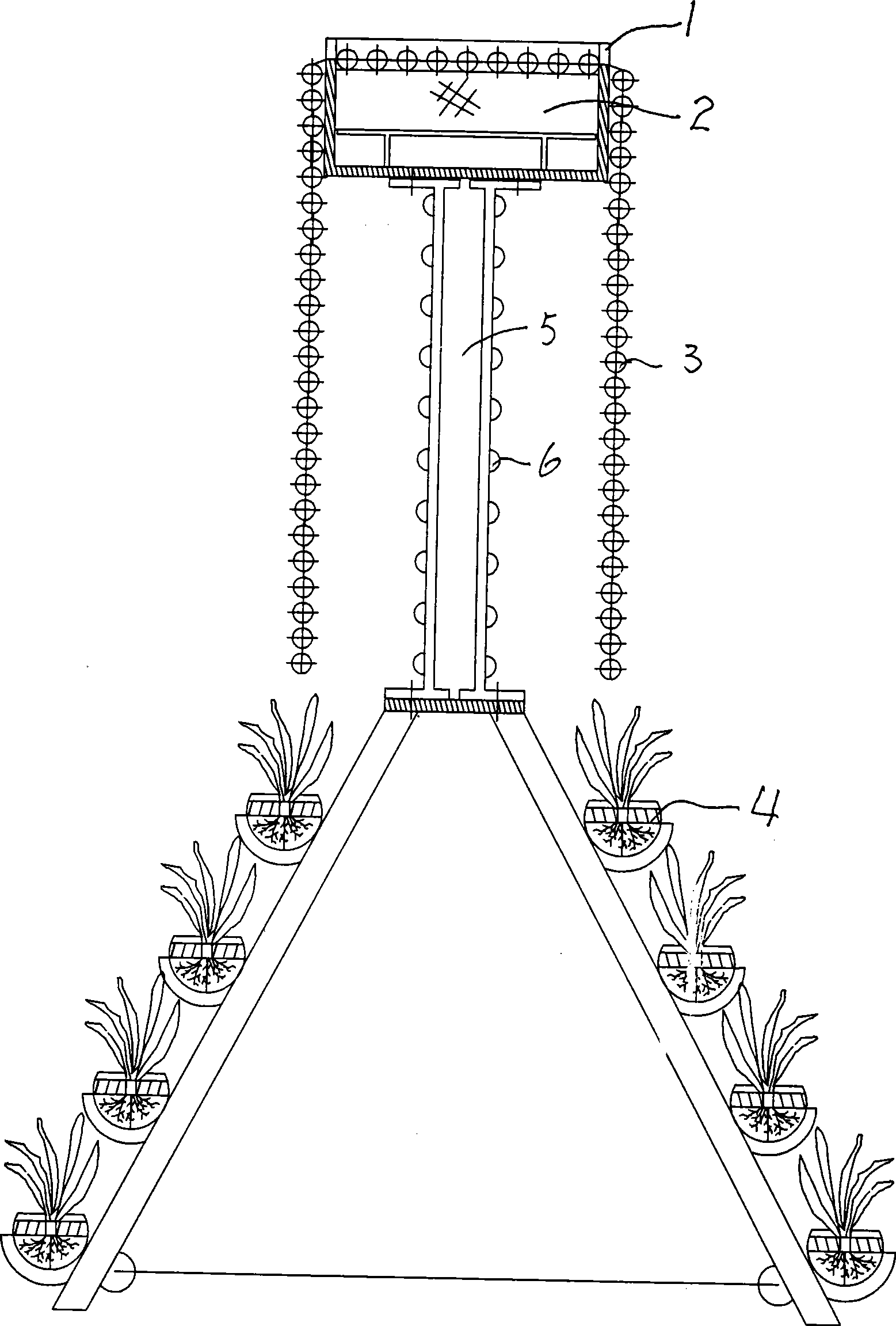

[0017] 2) The surface of glass beads is burnt and plated with TiO 2 It is a photocatalytic film, and the whole beads are transparent. Holes are set in the middle of the glass beads, which are connected in series by nylon wires, and are connected in parallel to vertically hang the side walls of the filter tank to form a glass pearl photocatalytic reaction curtain 3, which hangs down to align with the plant c...

Embodiment 2

[0026] The TiO on the surface of the glass beads 2 The photocatalytic material is a TiO2 thin film catalyst doped with Ag nanoparticles coated on the surface of glass beads:

[0027] The conditions are as follows: tetra-n-butyl titanate is used as titanium source, nitric acid and acetylacetone are used as hydrolysis inhibitor, deionized water is used as hydrolysis agent, polyethylene glycol and 1,5-pentanediol are additives, and silver nitrate is used as silver source.

[0028]Pipette 4 ml of tetra-n-butyl titanate, dissolve it in 1 ml of acetylacetone and stir for 0.5 hour to prepare solution A. In addition, 0.1 g of silver nitrate, 1 g of polyethylene glycol, 0.25 g of 1,5-pentanediol, and 0.7 g of water were dissolved in 32.5 ml of ethanol to prepare solution B. Solution B was slowly added dropwise to solution A and stirred for 1 hour, and an appropriate amount of concentrated nitric acid was added to adjust the acidity to obtain a precursor sol.

[0029] Soak the glass b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com