Positive and negative separation type LED component, automobile lamp and flashlight

A LED component, positive and negative technology, applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve the problems of slow heat conduction at the LED grain and difficult breakthroughs in heat dissipation performance, so as to improve heat dissipation efficiency, overcome technical prejudice, improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present case will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

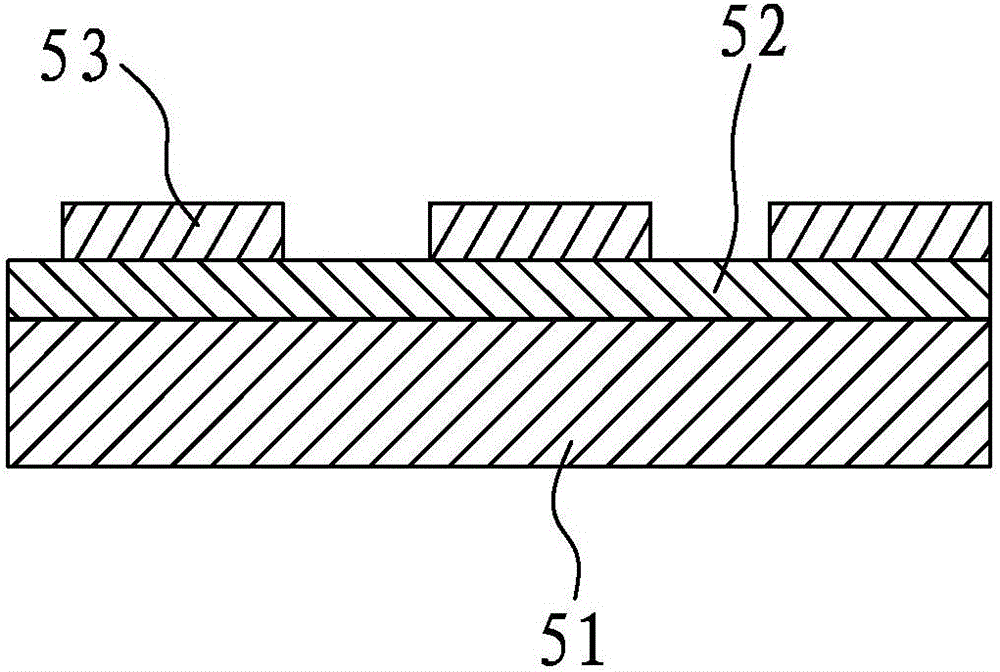

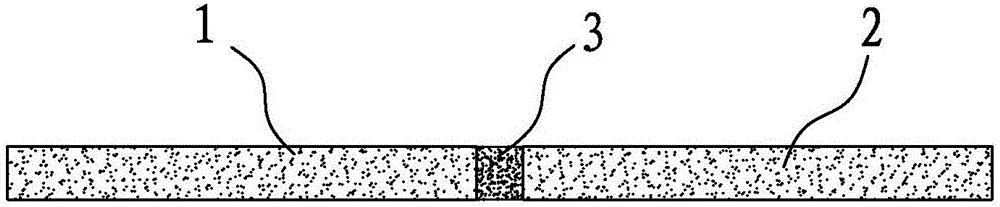

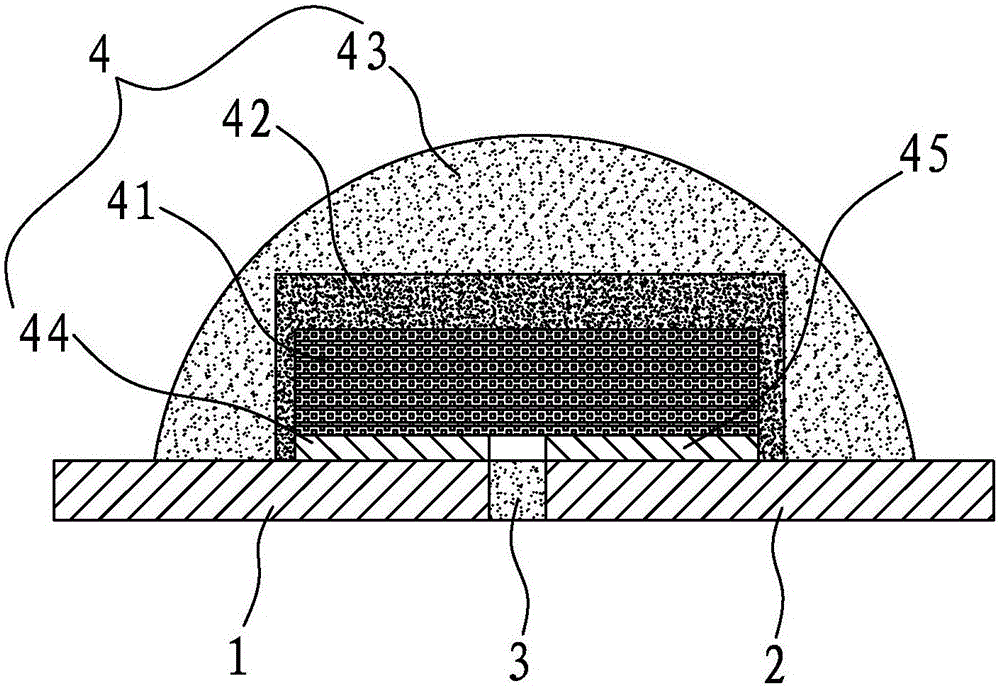

[0048] like figure 2 and image 3 As shown, the present invention relates to a positive and negative separated LED assembly, which has an electrically conductive and thermally conductive positive plate 1, an electrically conductive and thermally conductive negative plate 2, and an insulator 3 located between the electrically conductive and thermally conductive positive plate 1 and the electrically conductive and thermally conductive negative plate 2, the electrically conductive and thermally conductive positive plate The plate 1 is electrothermally connected with the anode of the LED crystal bead 4 , and the conductive and heat-conducting negative plate 2 is electrothermally connected with the cathode of the LED crystal bead 4 . In this embodiment, the conductive and thermally conductive positive plate 1 and the conductive and thermally co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com