A kind of open-hole well outside wrapping expansion filling sand control method

A wrapping, open-hole well technology, applied in wellbore/well components, earthwork drilling, fluid production, etc., can solve the problems of unstable formation sand, sand control failure, oil and gas well production decline, etc., to improve the overall sand control strength, The effect of high filling density and good deformation and expansion function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

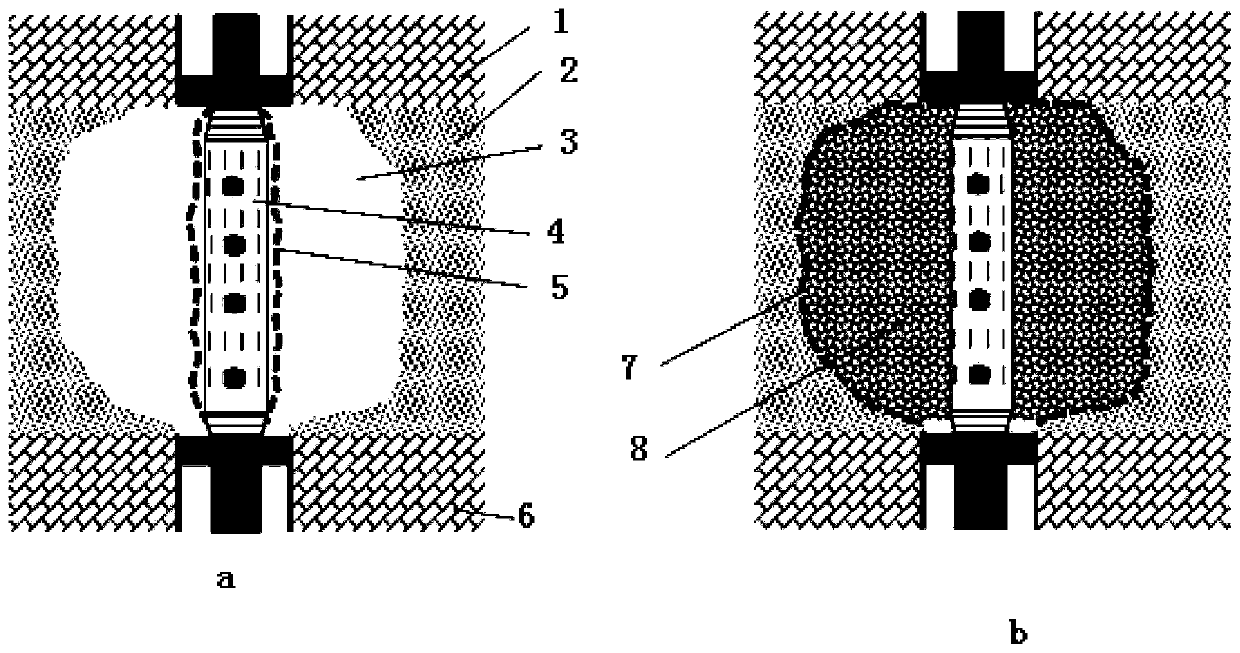

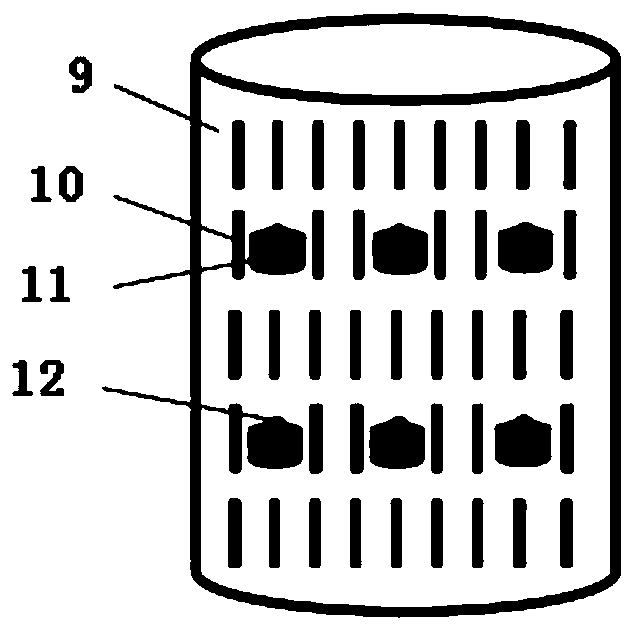

[0049] A method for sand control of open-hole wells, which uses high-expansion packing sand control screens with external inclusions for sand control, and the sand control screens are high-expansion packing sand control screens with external inclusions, and the structure is as follows: figure 2 as shown,

[0050] It includes a slotted base screen tube 9, and the outside of the slotted base screen tube 9 is provided with a free-expanding outer inclusion 5. The free-expanding outer inclusion 5 is in the form of a ring as a whole, and is sleeved on the outside of the slotted base screen tube 9 to expand freely. The two open ends of the outer inclusions 5 are fixed to the two ends of the slotted base screen tube 9, and radial through-slits are set on the freely expanding outer inclusions 5, and the screen filling is formed between the slotted base screen tube and the freely expanding outer inclusions space.

[0051] The free-expanding outer inclusion 5 is a flexible metal chain ...

Embodiment 2

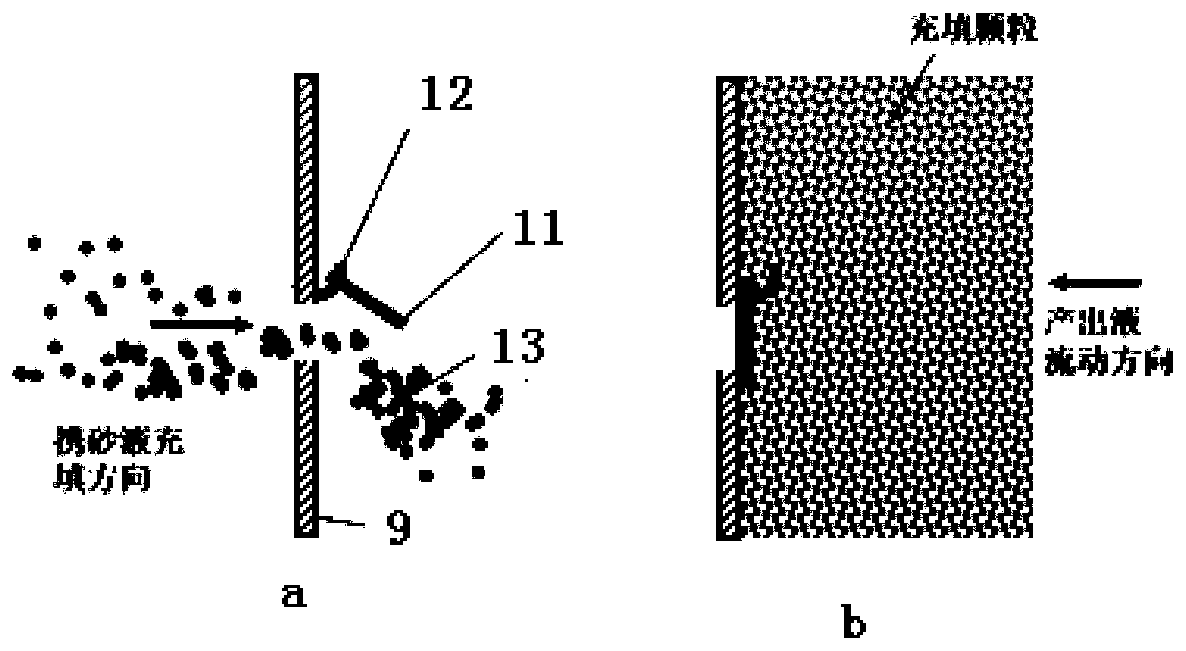

[0065] A sand control method for wrapping expansion packing in an open-hole well, which is the same as that described in Example 1, except that:

[0066] Outer inclusions are filled with high-expansion sand control screens, and the free-expanding outer inclusions 5 are flexible metal chain nets. The flexible metal chain nets are metal chain nets with meshes woven from fine metal sheets. 2 / 3 of the particle size of the solid particles in the sand fluid.

[0067] The freely expanding external inclusions 5 surround the slotted matrix screen 9 when shrinking and overlapping, and after being impacted and expanded by the liquid flow, their surface area expansion rate is 20 times that of shrinking and overlapping. 5 times.

[0068] On the side wall 9 of the screen pipe of the slotted substrate, three circles of sand injection holes are arranged at intervals up and down, and three circles of sand injection holes are evenly spaced on each circle, and each sand injection hole is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com