Method for continuously and synchronously hydrolyzing acylation reaction liquid

A technology of acylation reaction and hydrolysis reaction, applied in the field of continuous synchronous hydrolysis of acylation reaction liquid, can solve the problems of polluted air, long time, turbidity, etc., and achieve the effect of improving material balance rate and facilitating collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

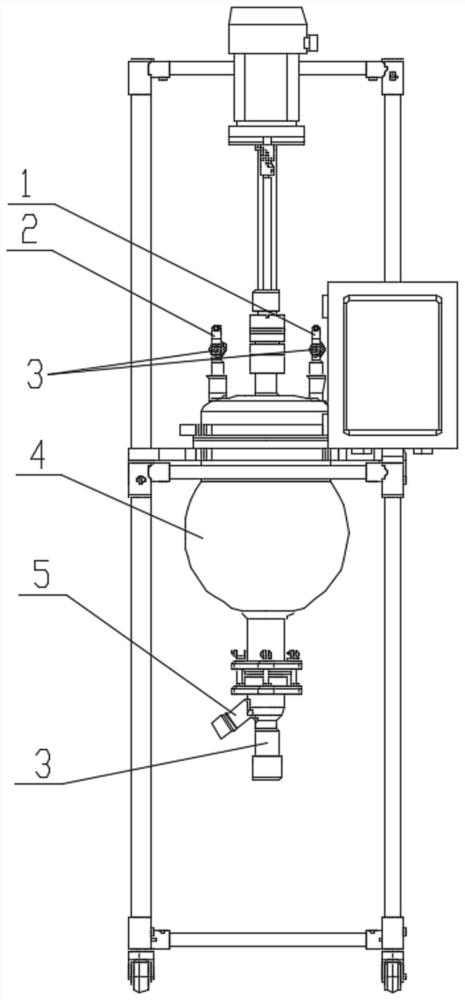

[0038] Embodiments of the application are described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below by referring to the figures are exemplary, and are intended to explain the present application, and should not be construed as limiting the present application.

[0039] Refer to the attached figure 1 A method for continuous and synchronous hydrolysis of the acylation reaction solution in the embodiment of the present application is described.

[0040] The embodiment of the present application proposes a method for continuous synchronous hydrolysis of the acylation reaction liquid, comprising the following steps:

[0041] 1. Acylation segment:

[0042] The preparation of acylation reaction solution comprises the following steps:

[0043] S1, preparation of acylation solution: put the reactor equipped with a stirring device into a constant temperature tank, add 600g of nitrobenzene, 200g of anhydrous aluminum tri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com