Industrial abraum salt decomposition treatment device and method

A technology for analytical treatment and industrial waste salt, which is applied in separation methods, chemical instruments and methods, and solid waste removal. It can solve problems such as high requirements for feed composition, small processing scale, secondary pollution, etc., and achieve equipment investment intensity. And the effect of low operating cost, strong feed adaptability and no secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the drawings.

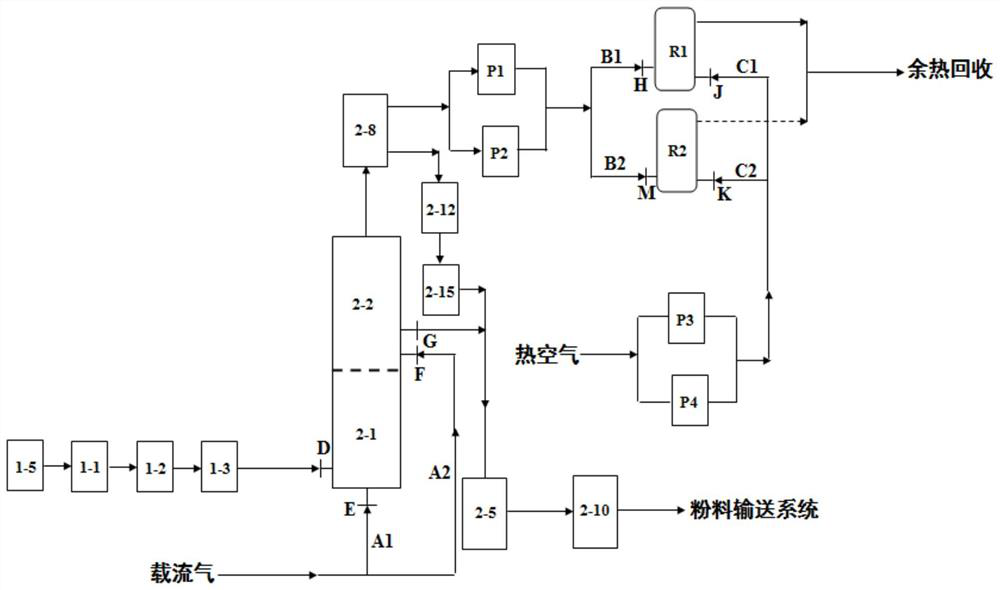

[0028] See figure 1 , The device of the present invention includes a coarse salt feed system, a coarse salt desorption system and a desorption gas conversion system;

[0029] The coarse salt feeding system includes a raw material storage bin 1-5, a coarse material buffer bin 1-1, a coarse material feed bin 1-2, and a coarse material conveyor 1-3 which are sequentially connected;

[0030] The coarse salt analysis system includes a first-stage analysis furnace 2-1 and a second-stage analysis furnace 2-2 that are connected from bottom to top, and the first-stage analysis furnace 2-1 passes through the feed nozzle D and the coarse salt feed system The coarse material conveyors 1-3 are connected, the first-stage analysis furnace 2-1 and the second-stage analysis furnace 2-2 are respectively connected to the carrier gas through the first-stage carrier gas nozzle E and the second-sta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com