Industrial waste salt converting device and method

A technology for industrial waste salt and conversion devices, which is applied in chemical instruments and methods, separation methods, transportation and packaging, etc., and can solve problems such as low-temperature molten salt corrosion, inability of equipment to operate stably for a long period, and complex process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

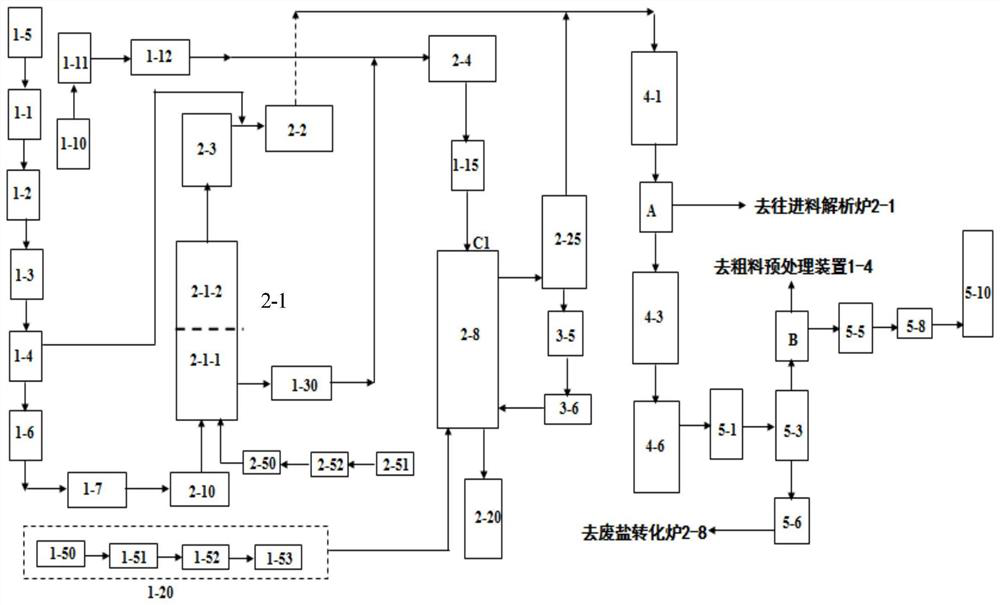

[0035] see figure 1 , including feed system, waste salt conversion system, particle circulation system, flue gas waste heat recovery system and tail gas post-treatment system;

[0036]The feed system includes a raw material feed system and an auxiliary agent feed system;

[0037] The waste salt conversion system includes a feed desorption furnace 2-1 connected to a raw material feeding system and a carrier gas injection system, and the outlet of the feed desorption furnace 2-1 is respectively separated from the raw material conveyor 1-30 and the desorption gas The feeder 2-3 is connected, the outlet of the raw material conveyor 1-30 and the additive feeding system are respectively connected with the inlet of the feed premixer 2-4, and the outlet of the feed premixer 2-4 is passed through the mixing feeder 1 -15 is connected to the inlet C1 of the waste salt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com