System and method for realizing wastewater reuse by removing ammonia nitrogen through three-dimensional electrolysis of liquid-solid fluidized bed

A technology of ammonia nitrogen wastewater and fluidized bed, which is applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problems of particle electrode agglomeration, tank body heating, current short circuit, etc., and meet the requirements of reuse Requirements, Cost Savings, Well Mixed Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

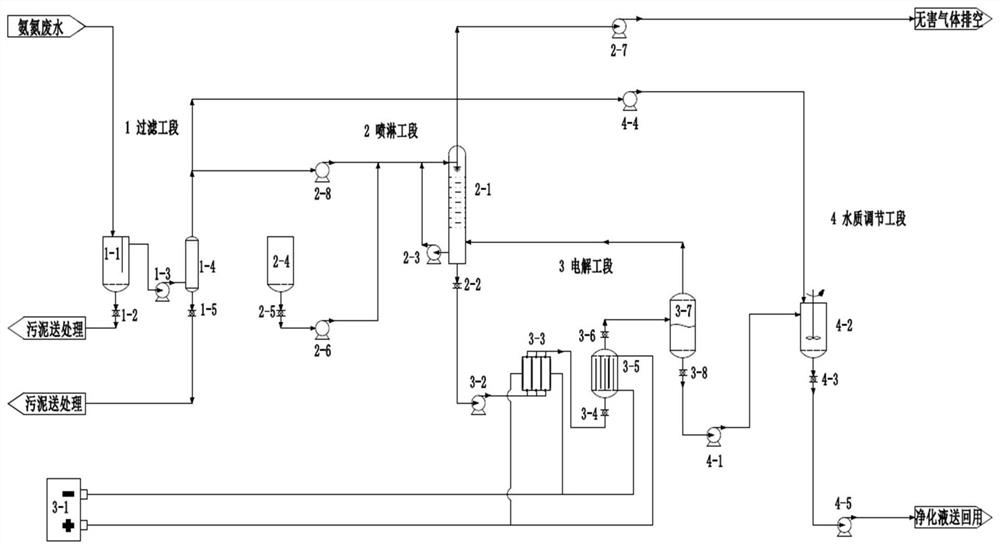

[0066] combine figure 1 , a liquid-solid fluidized bed three-dimensional electrolytic ammonia nitrogen removal system used in this embodiment to realize wastewater reuse, including a filtering section 1, a spraying section 2, an electrolysis section 3 and a water quality adjustment section 4;

[0067] Filtration section 1 includes gravity settling tank 1-1, settling tank blowdown valve 1-2, filter inlet pump 1-3, filter 1-4 and filter blowdown valve 1-5;

[0068] Spray section 2 includes spray tower 2-1, spray tower drain valve 2-2, spray pump 2-3, catalyst tank 2-4, catalyst feed valve 2-5, catalyst feed pump 2-6, Induced fan 2-7 and spray tower feed pump 2-8;

[0069] Electrolysis section 3 includes DC power supply 3-1, electrolyzer feed pump 3-2, plate and frame electrolyzer 3-3, fluidized bed electrolysis inlet valve 3-4, fluidized bed electrolyzer 3-5, fluidized bed electrolyzer Liquid outlet valve 3-6, gas-liquid separation tank 3-7 and separation tank drain valve 3-8;...

Embodiment 2

[0078] In this embodiment, the method of removing ammonia nitrogen by three-dimensional electrolysis of the liquid-solid fluidized bed described in Embodiment 1 to realize the reuse of wastewater includes the following steps:

[0079] The ammonia nitrogen waste water is sent to the gravity settling tank 1-1, and after gravity settling, the supernatant and sludge are obtained; the sludge is discharged through the settling tank blowdown valve 1-2 and sent for treatment; the supernatant is sent in through the filter inlet pump 1-3 In the filter 1-4, the filtered clear liquid and filtered sludge are obtained; the filtered sludge is discharged through the filter sewage valve 1-5 and sent for processing; a part of the filtered clear liquid is sent to the spray tower 2 through the spray tower feeding pump 2-8 -1; another part of the filtered clear liquid is sent into the regulating tank 4-2 through the raw water pump 4-4 of the regulating tank; the catalyst in the catalyst tank 2-4 pa...

Embodiment 3

[0082] In this embodiment, the printing and dyeing wastewater of a certain enterprise is used as the treatment object, and the treatment capacity is 15m 3 / h, the initial value of ammonia nitrogen is 10000. In the spraying section 2, the catalyst is a sodium chloride solution, and the amount of the catalyst added is 2% of the mass of the ammonia nitrogen wastewater. The water flow in the plate and frame electrolyzer 3-3 is in parallel structure, and the current is in series structure. The anode in the plate and frame electrolytic cell 3-3 is a titanium electrode coated with platinum, ruthenium, iridium, tantalum, tin, antimony and manganese; the cathode is a titanium electrode; the distance between the anode and cathode is 2mm; the current density of the anode is 800A / m 2 . The built-in electrode in the plate-frame electrolytic cell 3-3 adopts an integrated bipolar plate structure, and the coated titanium electrode adopts a single-sided active coating. In the fluidized bed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com