Patents

Literature

117results about How to "Reduce Process Risk" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

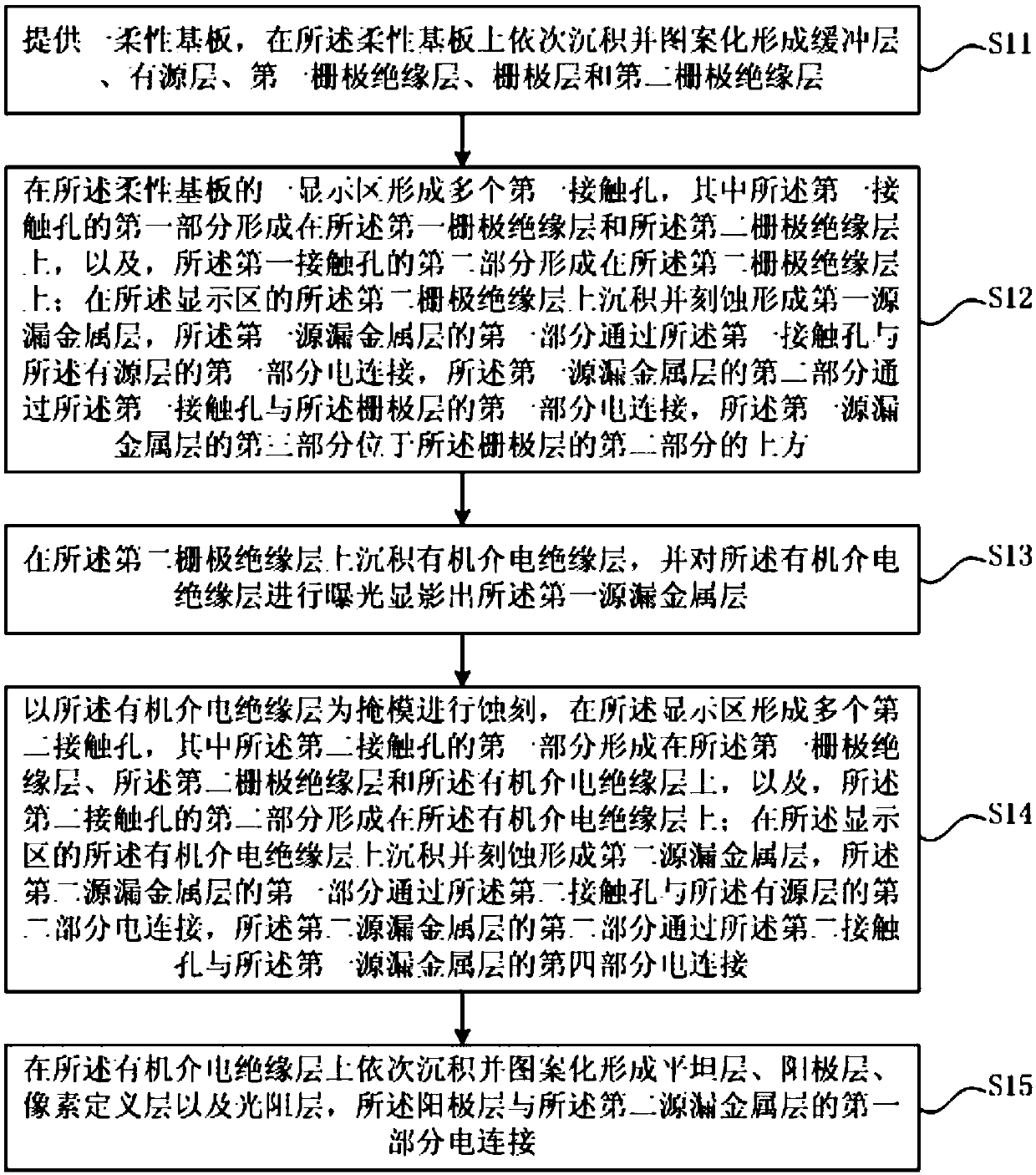

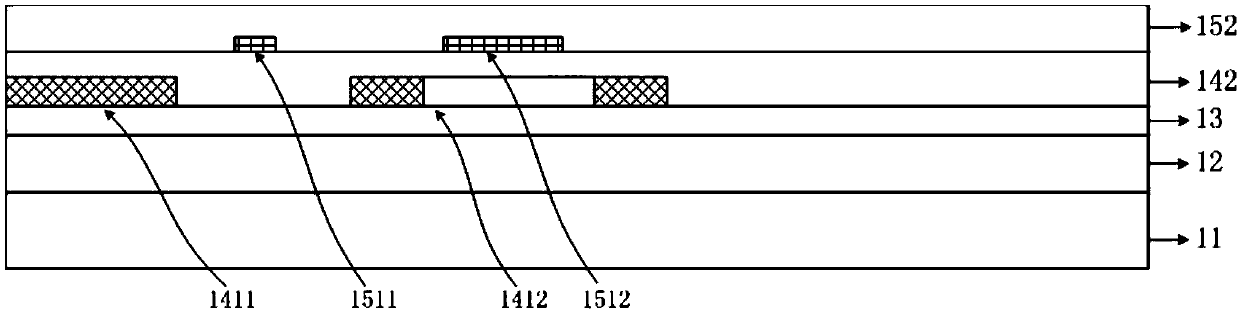

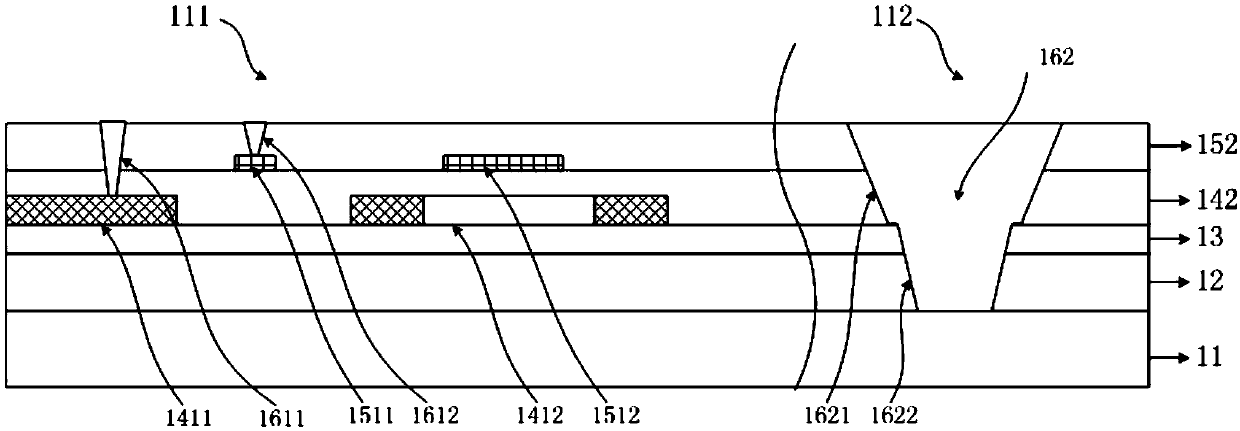

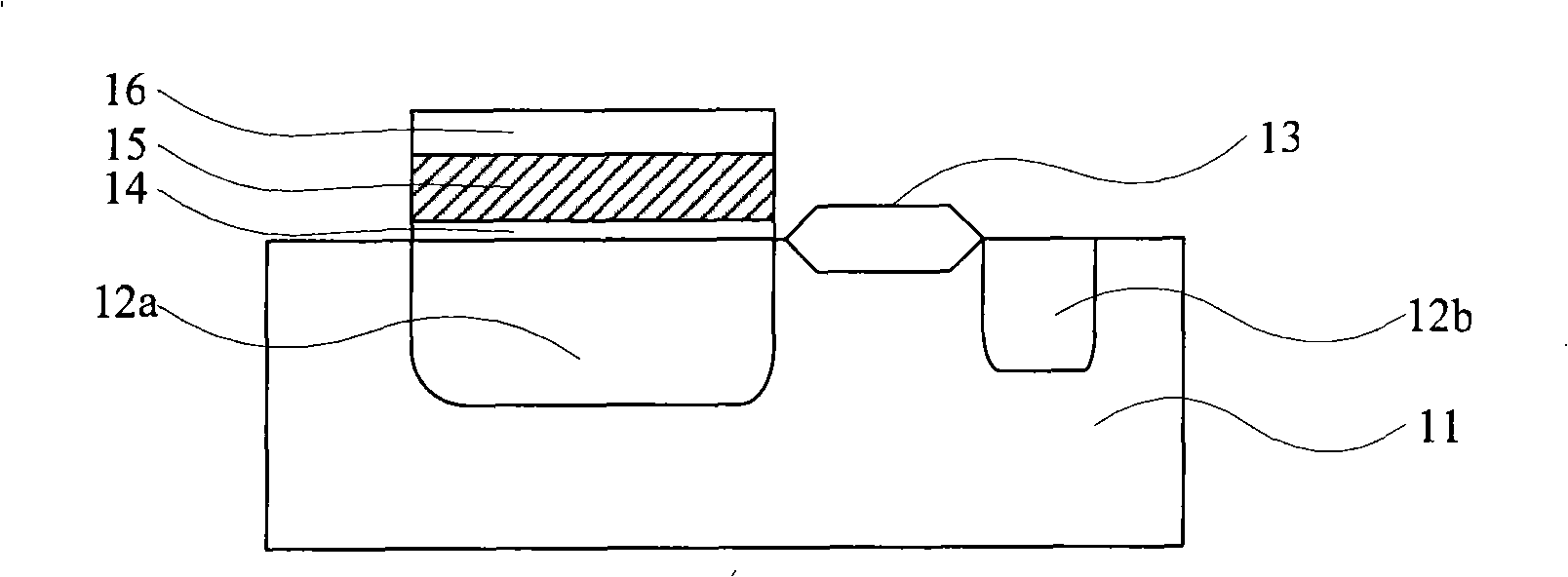

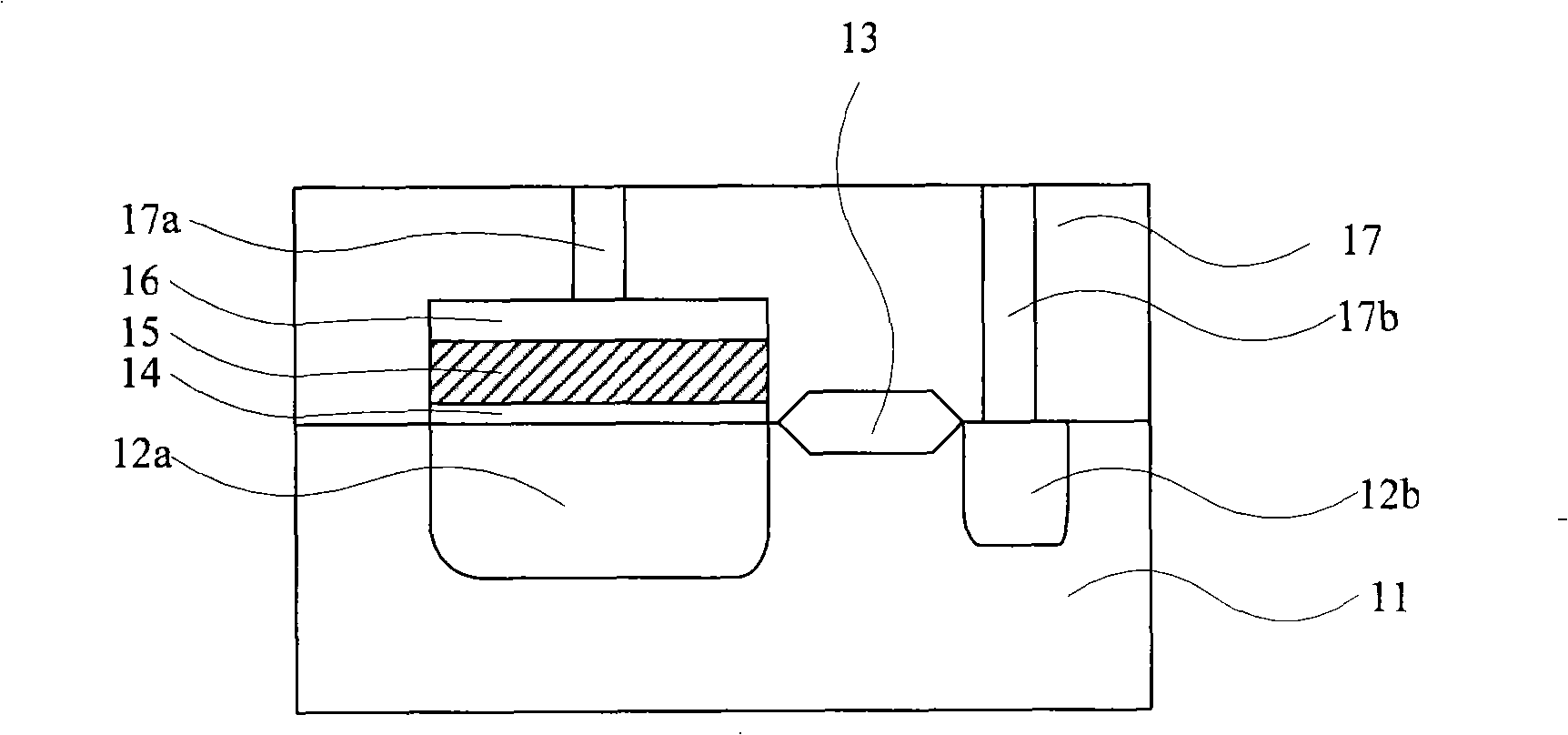

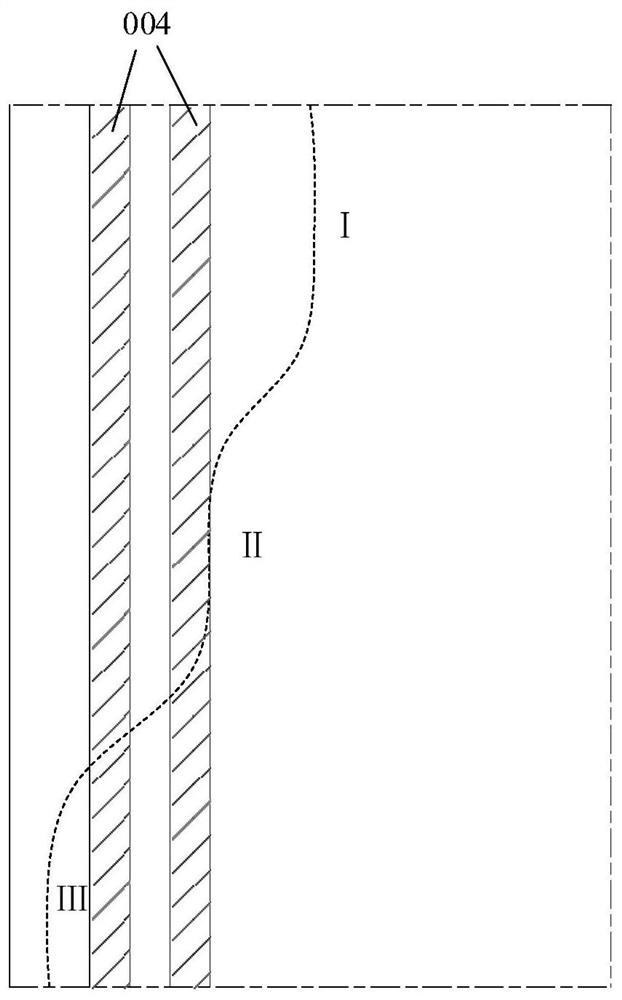

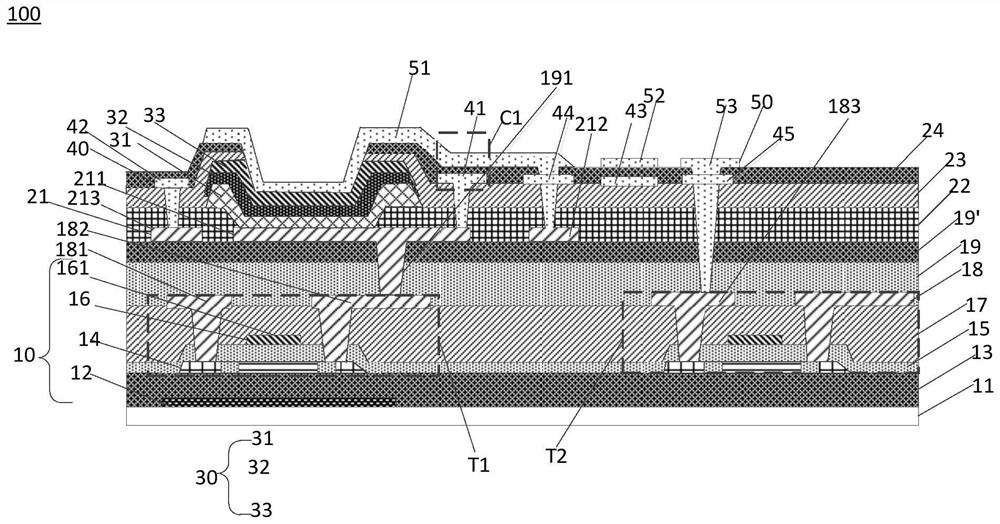

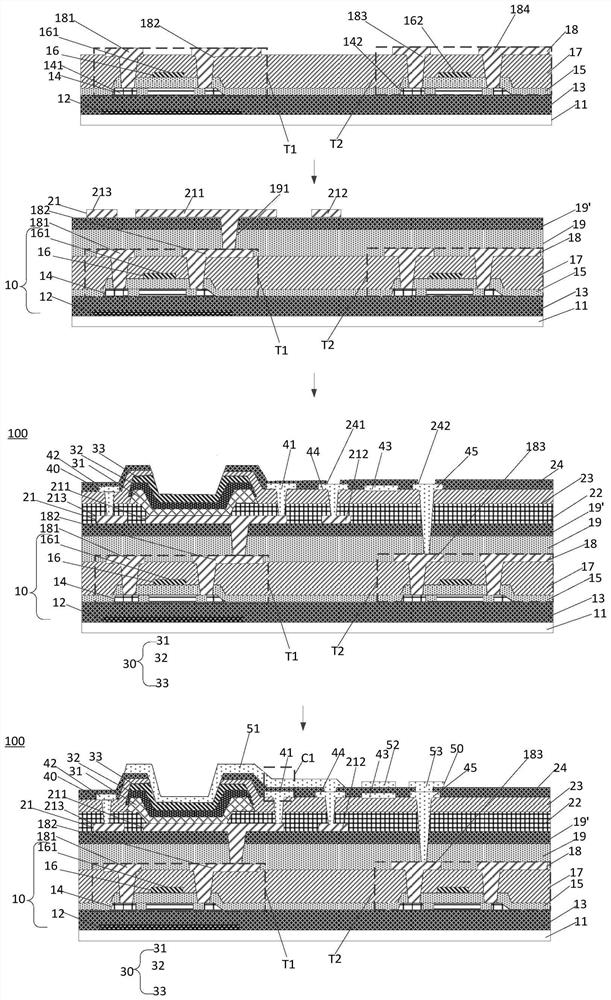

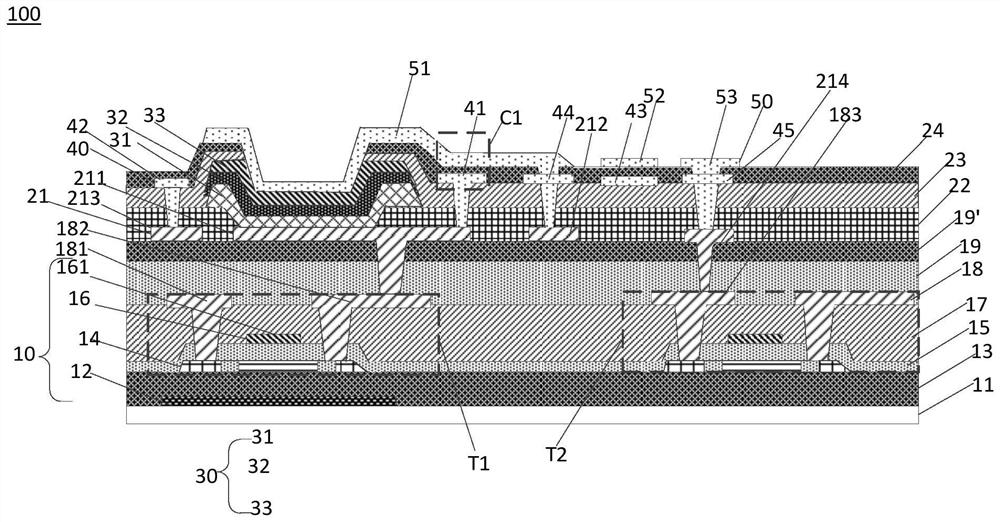

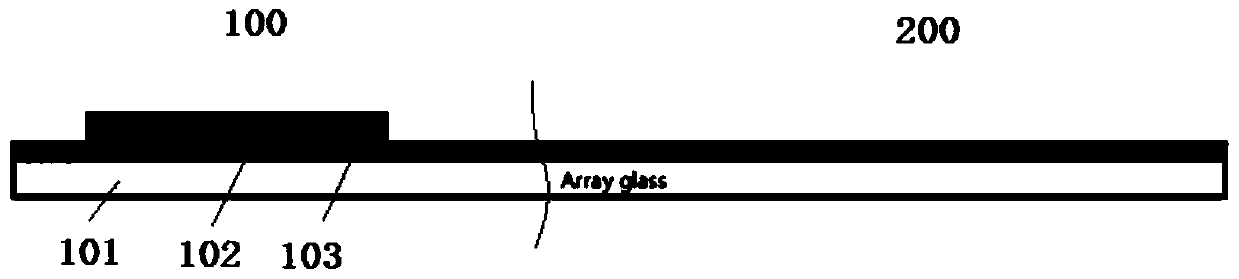

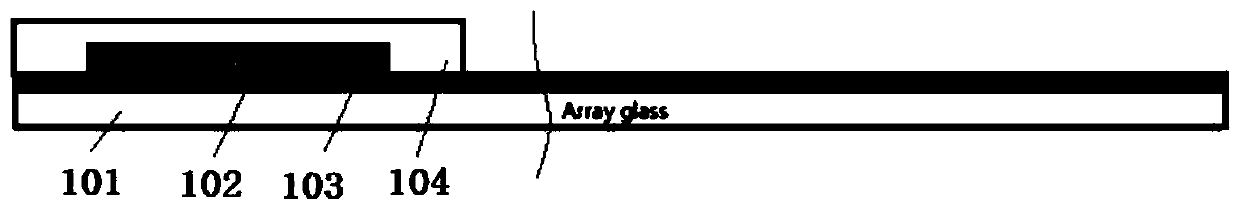

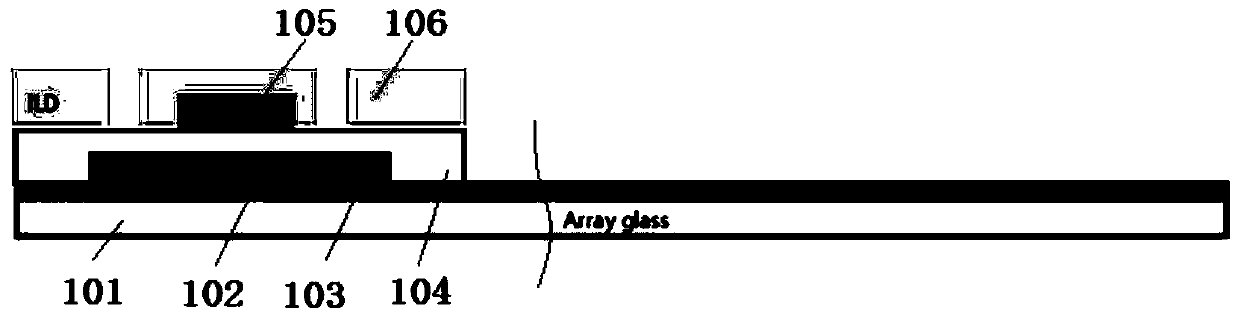

Flexible display panel and preparation method thereof

InactiveCN109686758AImprove bending performanceImprove display uniformityStatic indicating devicesDigital data processing detailsVoltage dropEngineering

The invention discloses a flexible display panel and a preparation method thereof. The bending performance of the flexible display panel is improved by adopting an organic material with better bendingperformance as a dielectric insulating layer; contact holes in a display area and deep holes in a bending area are dug behind an insulating layer of a second grid electrode, so that a part of the contact holes are completed in a first source drain metal layer to reduce the density of hole digging of a second source drain metal layer, and the high PPI is ensured while the bending performance of the panel is improved; double-layer SD structural processing is adopted, so that IR voltage drop can be reduced, and the display uniformity of the panel can be improved; wiring of the bending area is designed to be double-layer metal wiring, so that the IR voltage drop can be further reduced, and the processing risk is reduced.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

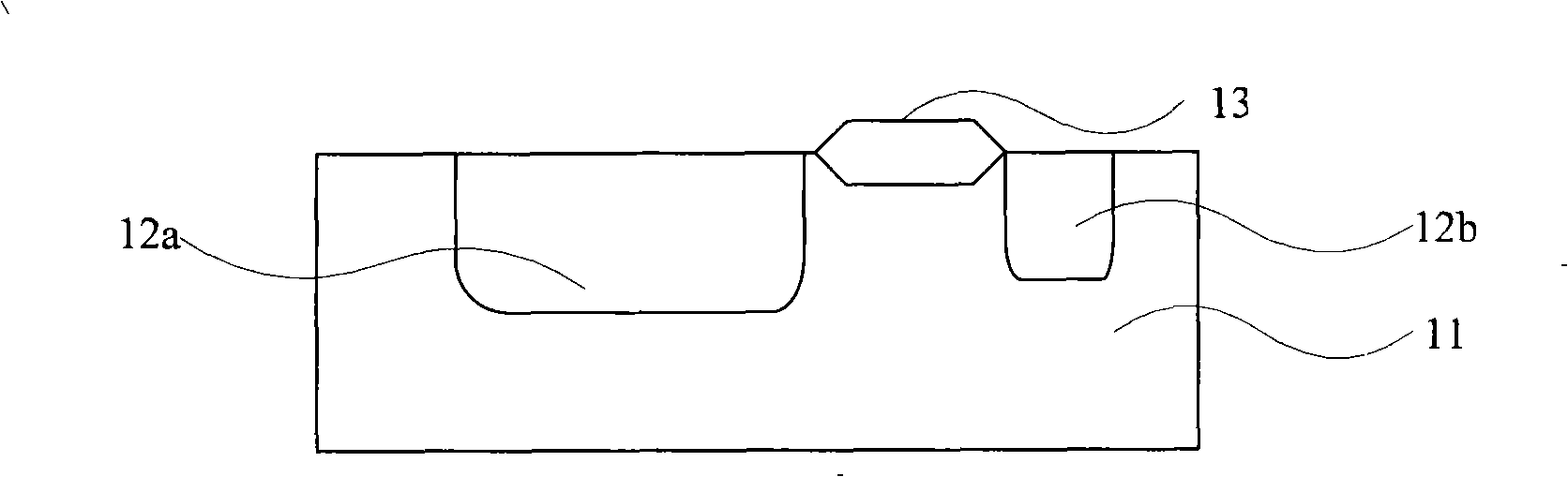

Structure for testing integrality of grid medium layer, forming method and test method thereof

ActiveCN101281898AGood repeatabilityBig errorSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsRepeatabilityMedia layer

A forming method of a grid dielectric layer integrality test structure includes: forming an insulated groove in a semiconductor substrate as active region insulation; sequentially forming a dielectric layer, a multi-crystal silicon layer and an electrode layer on the semiconductor substrate; etching the dielectric layer, the multi-crystal silicon layer and the electrode layer to sequentially form a grid dielectric layer, a grid multi-crystal silicon layer and a grid electrode layer. Accordingly, the invention provides a test structure and a test method for grid dielectric layer integrality. The grid dielectric layer integrality test structure is formed by two layers of mask board and has analogous electricity test result to an existing grid dielectric layer integrality test structure formed by employing four layers of mask board, synchronously electricity test result repeatability of the grid dielectric layer integrality test structure of present invention is good, thereby saving technique cost, shortening technique circulation period and reducing technique risk.

Owner:SEMICON MFG INT (SHANGHAI) CORP

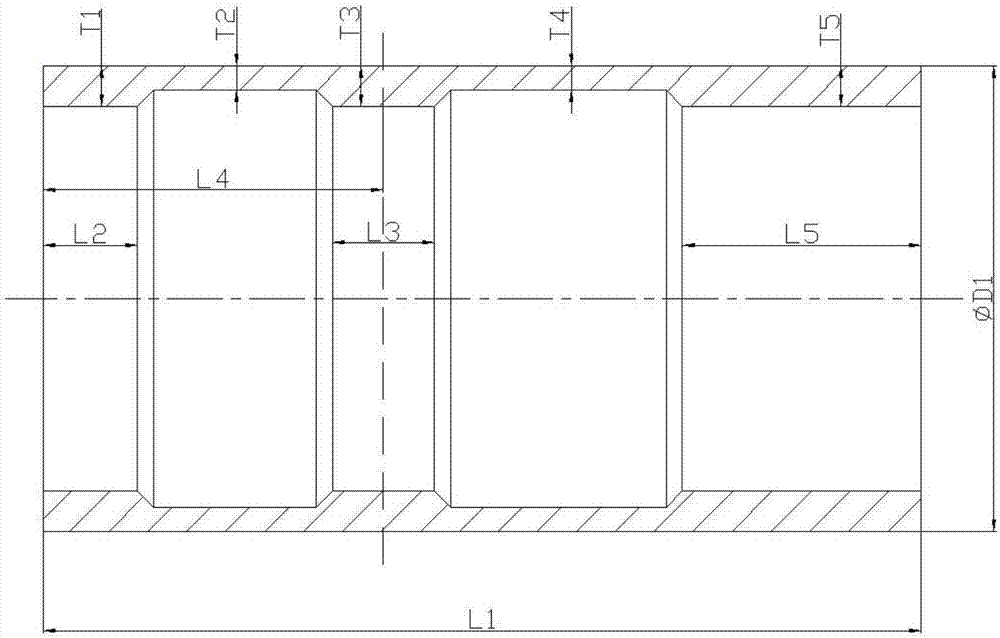

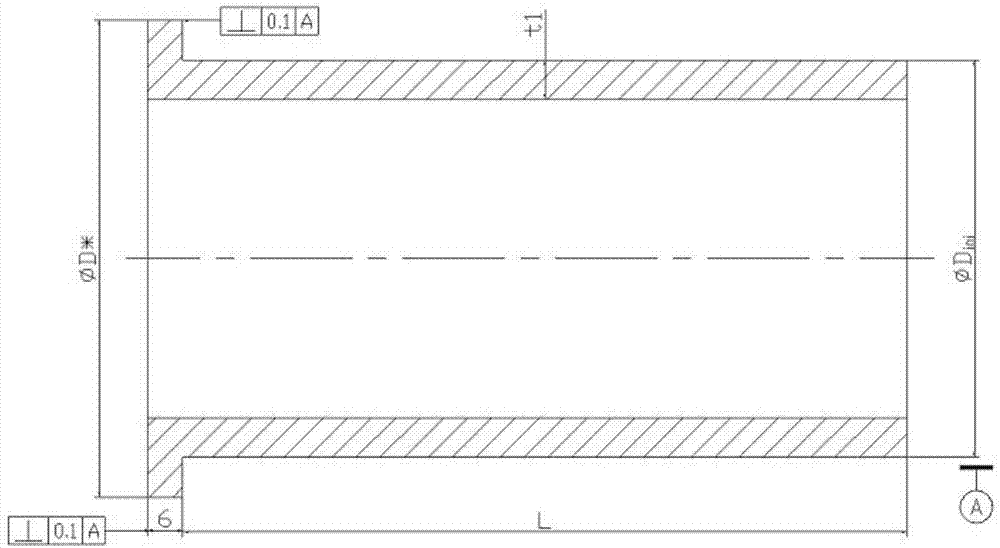

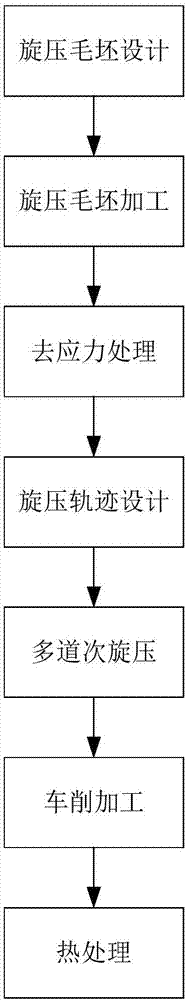

Multi-pass spinning forming method for long barrel with inner annular reinforcing ribs

ActiveCN107962098AIncrease profitReduce manufacturing costShaping toolsTechnological riskEngineering

The invention belongs to the technical field of spinning forming, and discloses a multi-pass spinning forming method for a long barrel with inner annular reinforcing ribs. An inner spinning technologyand a tension spinning technology are combined, only a set of annular core dies with different inner diameter sizes and the length being 400 mm are adopted to achieve multi-die multi-pass spinning forming of the long barrel part with the multiple inner annular reinforcing ribs and the length being 2m or less, and the part reinforcing rib position and size precision can be ensured. The method comprises the steps of spinning workblank design, spinning workblank machining, stress relief treatment, workblank installation adjusting, multi-pass spinning, turning, stress relief treatment and the like. Multi-pass low-cost forming of the long barrel with the inner annular reinforcing ribs is achieved, and the material utilization rate is greatly improved; and compared with a traditional technology, the technological risk and the difficulty of multi-pass accurate forming of the inner annular reinforcing ribs are lowered, the material cost is reduced, and the product quality is improved.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Low-cost extra-deep-drawing-quality cold-rolled galvanized steel strip and preparation method thereof

ActiveCN105648322AReduce contentGuaranteed timelinessHot-dipping/immersion processesChemical compositionNitrogen

The invention discloses a low-cost extra-deep-drawing-quality cold-rolled galvanized steel strip and a preparation method thereof. The steel strip is prepared from, by mass percent, 0.001% to 0.005% of C, 0.07% to 0.12% of Mn, not larger than 0.012% of S, not larger than 0.012% of P, not larger than 0.03% of Si, 0.010% to 0.060% of Als, not larger than 0.0040% of N, 0.0015% to 0.0030% of B and the balance Fe and inclusion within an allowed range. According to the galvanized steel strip, the reasonable carbon content is controlled to reduce the content of free carbon in steel as much as possible; and meanwhile, a certain amount of boron is added to fix interstitial nitrogen and part of carbon, and therefore the timeliness of an extra-deep-drawing-quality galvanized product can be guaranteed. According to the galvanized steel strip, boron is used for fixing carbon atoms, so that the cost of an alloy material is greatly reduced, meanwhile, the heating temperature and soaking temperature of a galvanization procedure can be greatly reduced, and therefore production difficulty and energy consumption are effectively lowered.

Owner:唐山钢铁集团高强汽车板有限公司 +2

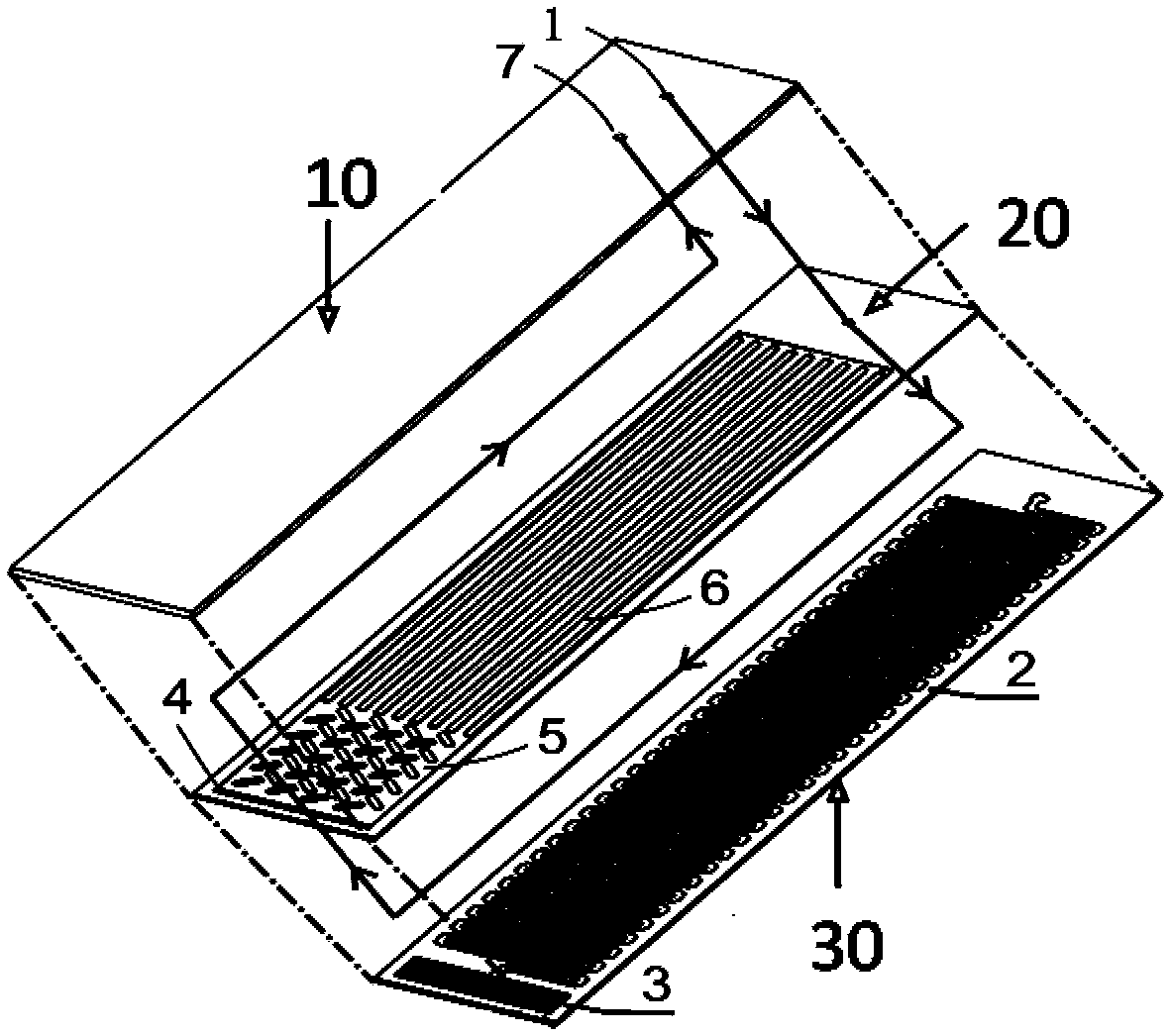

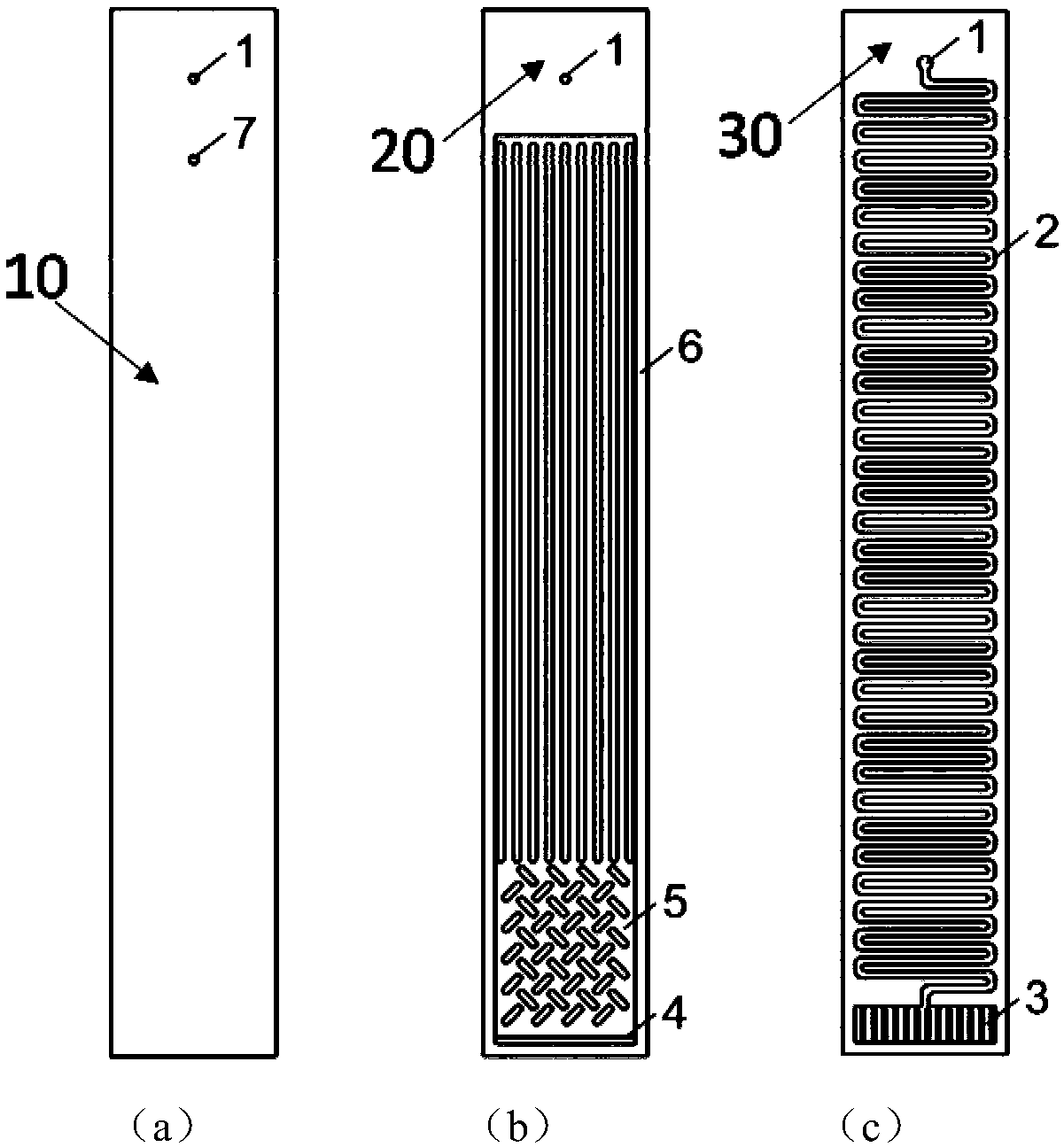

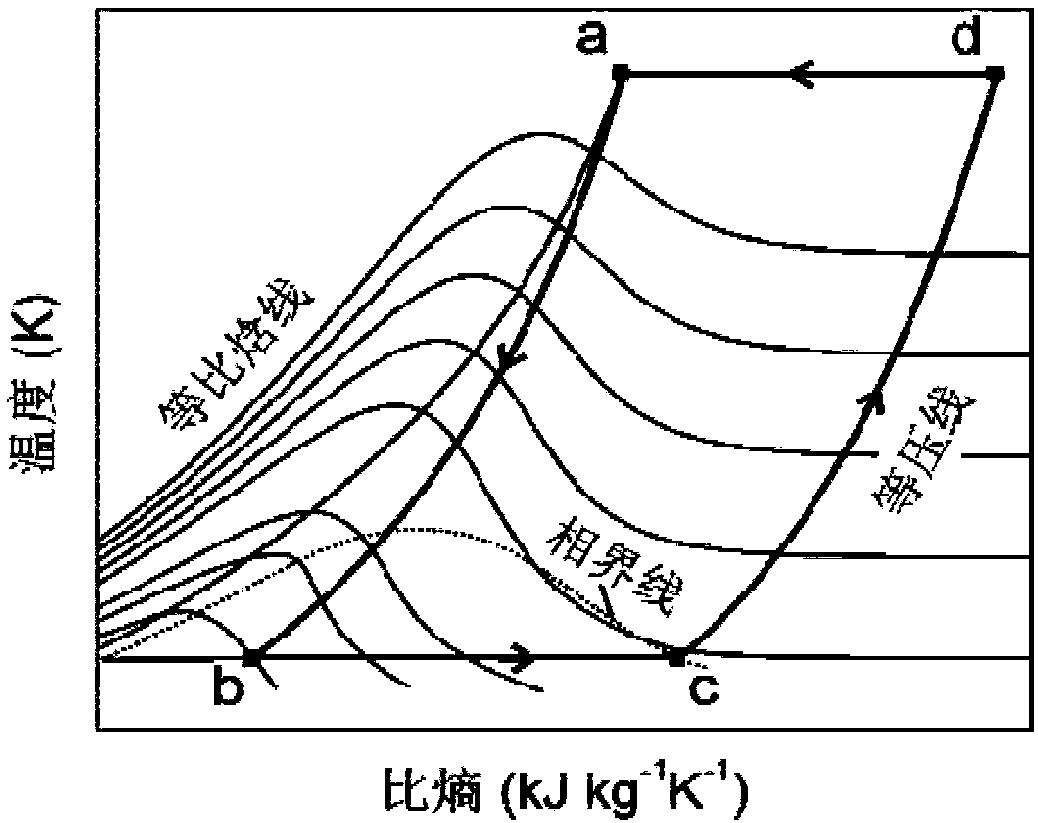

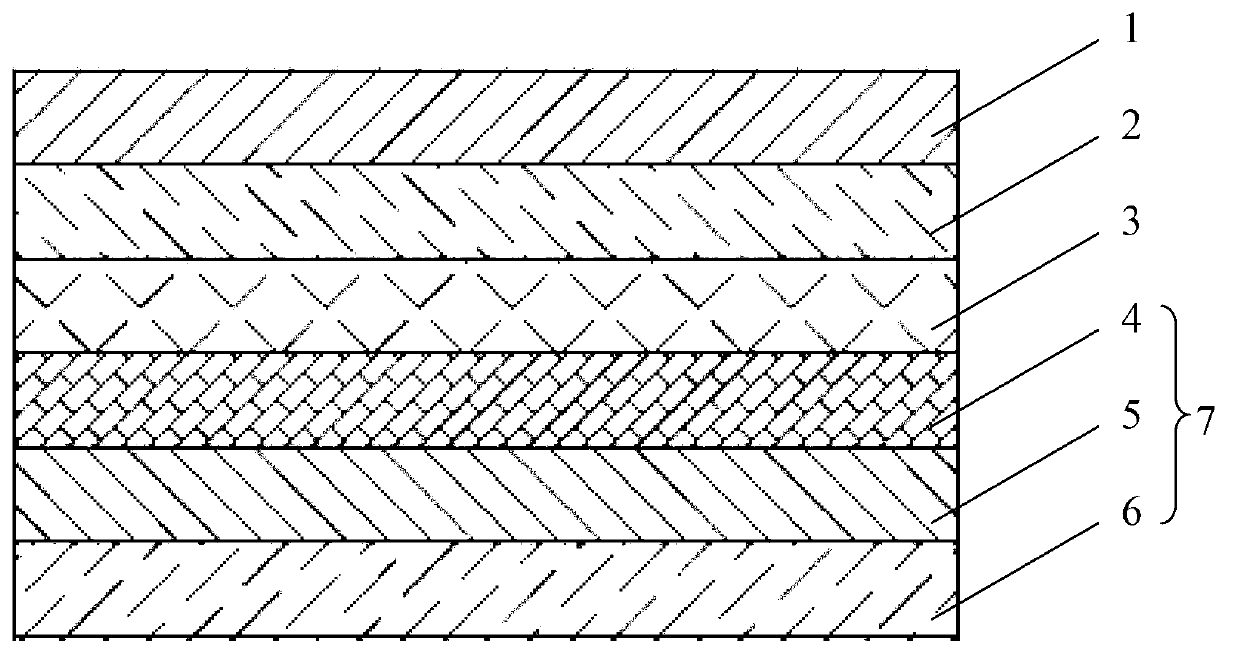

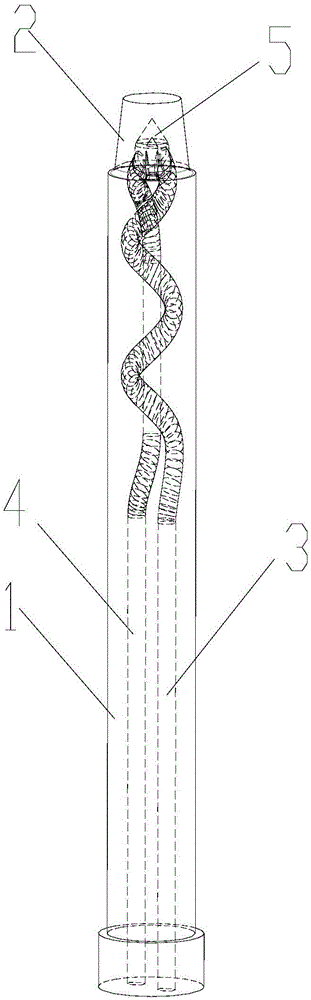

Miniature throttling refrigerating machine based on micro-electro-mechanical system heating technology

ActiveCN109579340AReduce processing difficultyReduce irreversible heat lossMechanical apparatusCompression machinesRefrigerated temperatureMechanical system

The invention discloses a miniature throttling refrigerating machine based on a micro-electro-mechanical system heating technology, and belongs to the technical field of miniature throttling refrigerators. An upper-layer substrate piece, a middle-layer substrate piece and a lower-layer substrate piece are welded into an integrated structure, working medium inlets are all formed in the corresponding position of one end of each layer of substrate piece, and a working medium outlet is further formed in the upper-layer substrate piece; the middle part and the other end of the lower-layer substratepiece are provided with a first micro-channel and a buffer chamber correspondingly, the first micro-channel is an S-shaped groove, one end of the micro-channel communicates with the working medium inlet at one end of the lower-layer substrate piece, and the other end of the micro-channel communicates with one end of the buffer chamber; a second micro-channel and a strip-shaped through hole are sequentially formed in the middle-layer substrate piece, one end of the micro-channel communicates with the working medium outlet of the upper-layer substrate piece, and the other end of the micro-channel communicates with the buffer chamber through the strip-shaped through hole. According to the machine, the blocking problem in the miniature throttling refrigerating machine can be effectively relieved, the flow and heat exchange in the evaporation process can be further enhanced while the machining procedure is simplified.

Owner:TSINGHUA UNIV

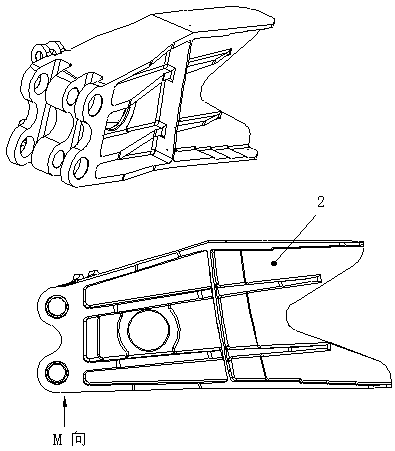

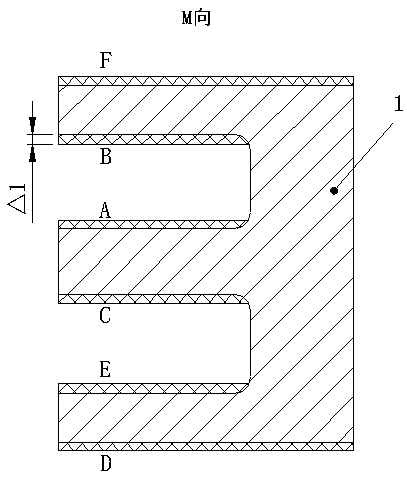

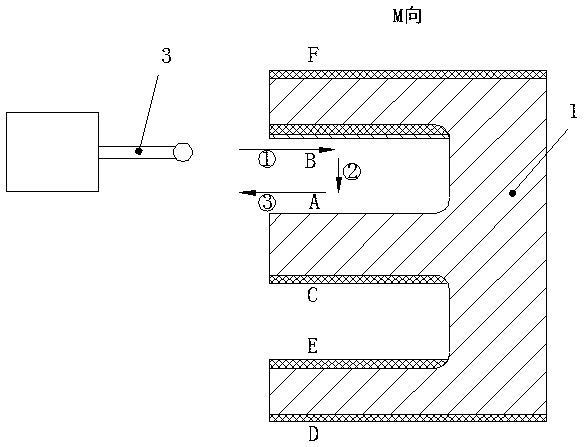

Aviation structural part high-precision lug group machining method

ActiveCN111390252AGuaranteed size requirementsImprove processing efficiencyMeasurement/indication equipmentsMilling equipment detailsAviationMilling cutter

The invention relates to an aviation structural part high-precision lug group machining method, and belongs to the technical field of machinery. The method comprises the following steps that firstly,a part lug group is subjected to rough machining and semi-fine machining through a milling cutter; then, a machining allowance is measured through a probe and is compared with a theoretical allowanceto form a program offset allowance P; and finally, the offset allowance P is automatically called by a program to finish high-precision lug group machining in place. According to the method, in the machining process, the manual intervention is not needed, high-quality machining on the high-precision lug group is rapidly completed, the machining efficiency is improved, the machining risk is reduced, the characteristics of simple operation method, reliable use, easy and wide use and the like are achieved, the machining quality of the part high-precision lug group can be effectively guaranteed, the rejection rate of parts is reduced, and therefore the cost is reduced.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

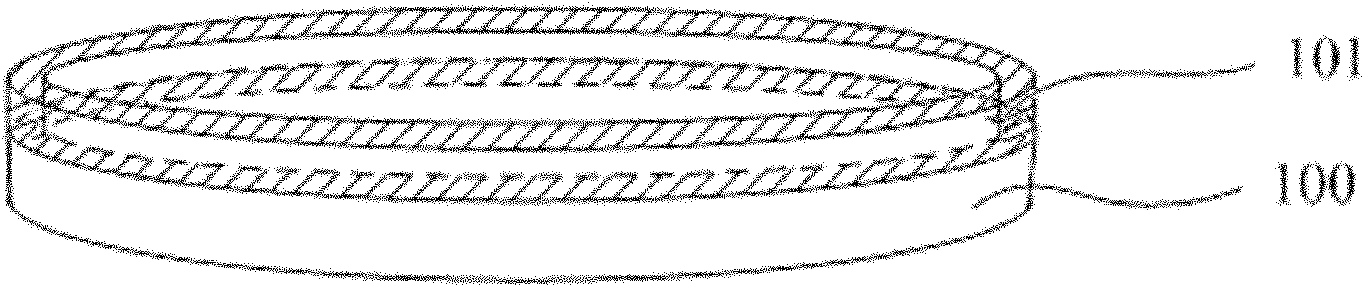

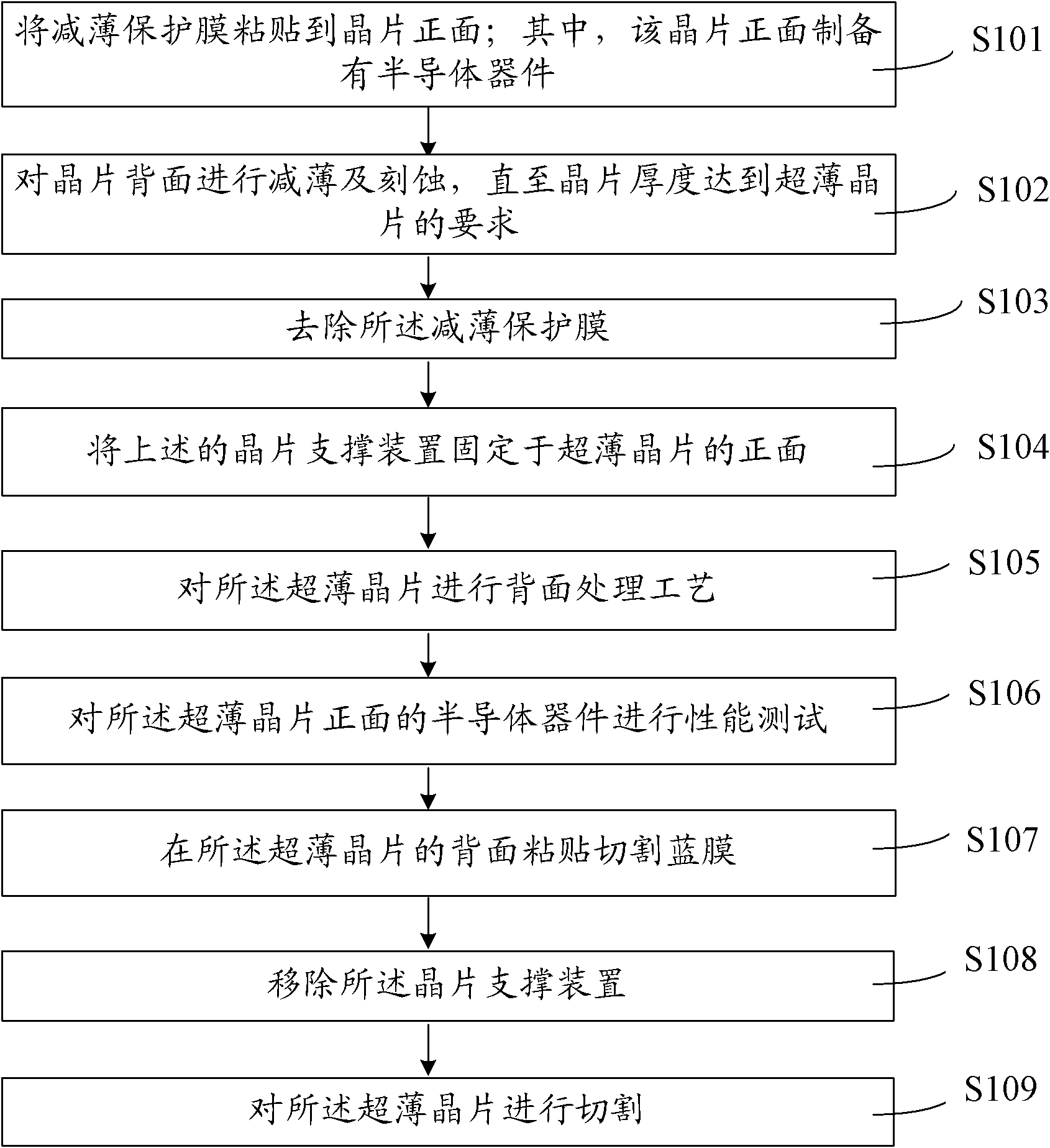

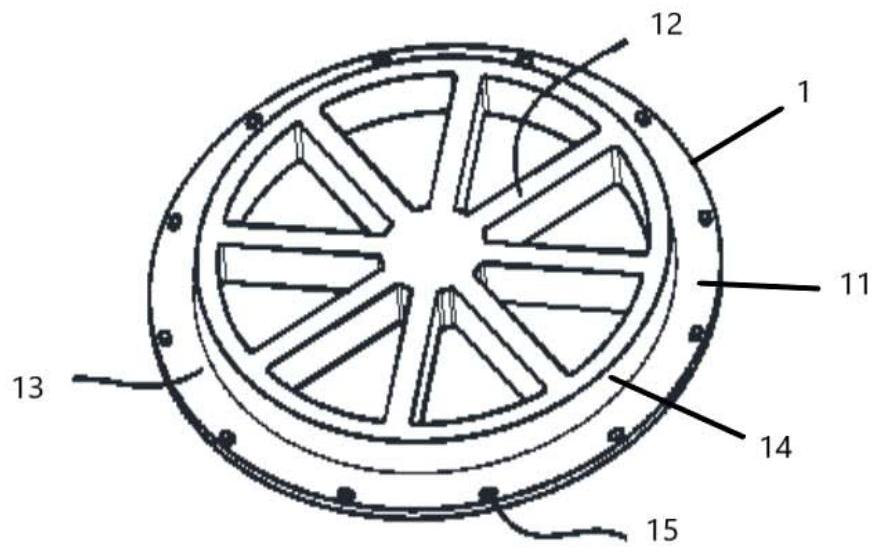

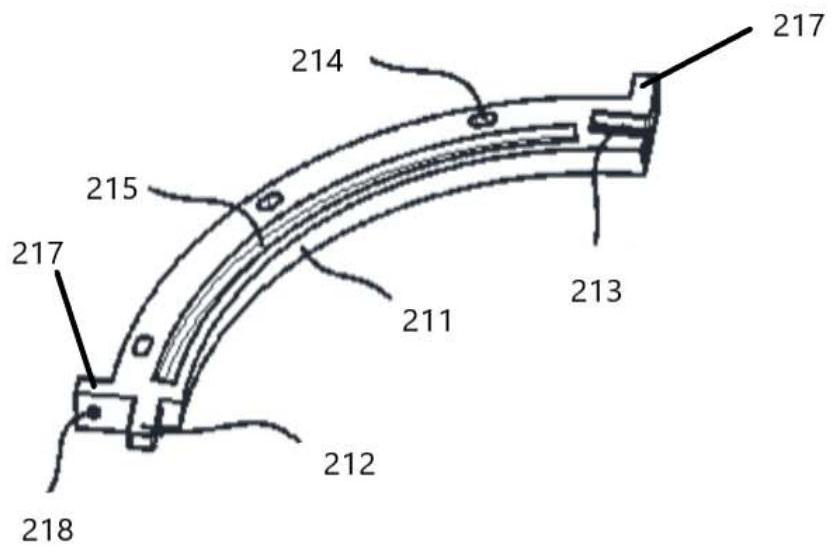

Wafer support device and wafer processing process

ActiveCN102157426ATimely feedbackTimely assessmentSemiconductor/solid-state device manufacturingSemiconductorSemiconductor device

The invention discloses a wafer support device. The device has an annular cylindrical structure so that a semiconductor device area on the front surface of an ultra-thin wafer cannot be blocked. Therefore, a performance test can be performed before encapsulating; problems in a process can be fed back and evaluated timely; and process risks are reduced. The invention also discloses a wafer processing process. In the processing process, the wafer support device is utilized for supporting the ultra-thin wafer in the process of a wafer back surface processing process and the performance test is performed after the wafer back surface processing, so that the problems in the process can be fed back and evaluated timely, and the process risks are reduced.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

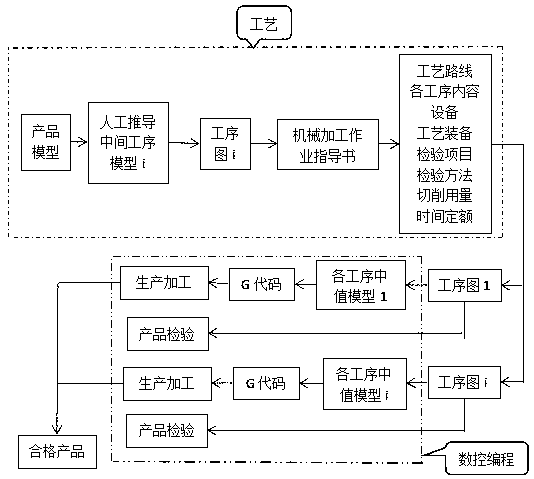

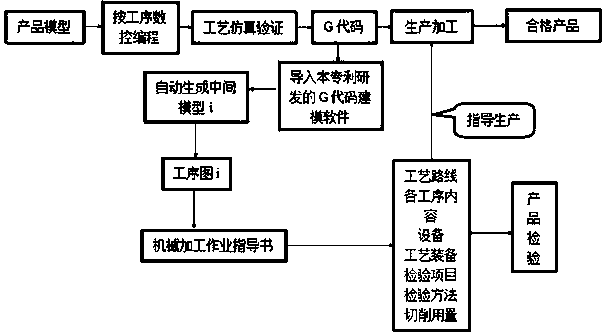

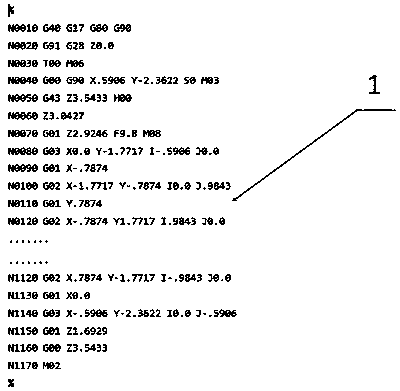

Mathematical modeling method based on G codes and application

PendingCN111353241AGuaranteed uniformityUniqueness guaranteedGeometric CADDesign optimisation/simulationCode generationAlgorithm

The invention discloses a mathematical modeling method based on G codes and an application. The mathematical modeling method actually comprises the following steps: importing the G codes of numericalcontrol machining into preset software, generating a tool path by utilizing the G code, and sweeping and cutting off a blank along the tool path by a tool so as to form a three-dimensional process intermediate model consistent with an actual machining process, wherein the three-dimensional process intermediate model is a three-dimensional mathematical entity model established on the basis of mathematical Boolean differencing operation, the same G codes are used for parametric modeling and also used for machine tool production and machining, and the uniformity, uniqueness and integrity of the model are ensured by utilizing data homology. According to the method and the application provided by the invention, existing processing programming software is utilized, modeling is carried out through G codes in a 3D environment, the bottleneck of three-dimensional digital design and manufacturing is solved by rapidly creating an intermediate model, a technical support is provided for datamationand intellectualization of a process platform, the compiling quality and efficiency of the process can be improved, and the method is good in universality and suitable for application and popularization.

Owner:GUIZHOU AEROSPACE PRECISION PRODS

Silver luster adhesive sticker label printed by adhesive sticker and preparation method thereof

The invention discloses a silver luster adhesive sticker label printed by an adhesive sticker and a preparation method of the silver luster adhesive sticker label. The silver luster adhesive sticker label comprises a transparent plastic layer, a high transparent double-sided adhesive layer, an ultraviolet (UV) ink printing layer and a silver luster adhesive sticker material composite layer, wherein the transparent plastic layer, the high transparent double-sided adhesive layer, the UV ink printing layer and the silver luster adhesive sticker material composite layer are composited in sequence. The silver luster adhesive sticker material composite layer comprises a silver luster adhesive sticker layer, an adhesive layer and a release film layer. The silver luster adhesive sticker layer contacts the UV ink printing layer. According to the silver luster adhesive sticker label printed by the adhesive sticker and the preparation method of the silver luster adhesive sticker label, only black UV ink is printed so as to play a role of light blocking. Highly difficult mirror surface silver wire mesh printing is changed to be ordinary adhesive sticker UV printing which is simple in craft. No special requirements aim at the cleanliness degree, the temperature and the humidity of a workshop. The silver luster adhesive sticker label printed by the adhesive sticker can be produced under an ordinary environment and is simple in craft, small in wastage and capable of greatly lowering the labor cost and the lost cost.

Owner:DALIAN SHENGFENG ADHESIVE PROD

Display device and display panel

PendingCN112002831AAvoid deficienciesThe problem of preventing overflow (over the first barrier dam)Solid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceInorganic layer

The invention relates to a display device and a display panel, and relates to the technical field of display. The display panel comprises a substrate, a driving layer, a light-emitting device layer, afirst blocking dam, a plurality of drainage strips and a packaging layer, wherein the driving layer is arranged on one side of the substrate and provided with a pixel circuit area, a peripheral circuit area and an edge area; the light-emitting device layer is arranged on one side, deviating from the substrate, of the pixel circuit region; the first barrier dam is arranged in the edge region and surrounds the peripheral circuit region; the drainage strips are arranged on the side, deviating from the substrate, of the edge area and located in the first blocking dam in a surrounding mode; each drainage strip extends to the peripheral circuit area from the edge area; the packaging layer comprises a first inorganic layer, an organic layer and a second inorganic layer; the first inorganic layercovers the light-emitting device layer, the first barrier dam and the drainage strip and protrudes in an area corresponding to the first barrier dam and the drainage strip; the organic layer is arranged on the surface, deviating from the substrate, of the first inorganic layer and is limited within the range surrounded by the first barrier dam; the second inorganic layer covers the organic layerand the first inorganic layer.

Owner:BOE TECH GRP CO LTD

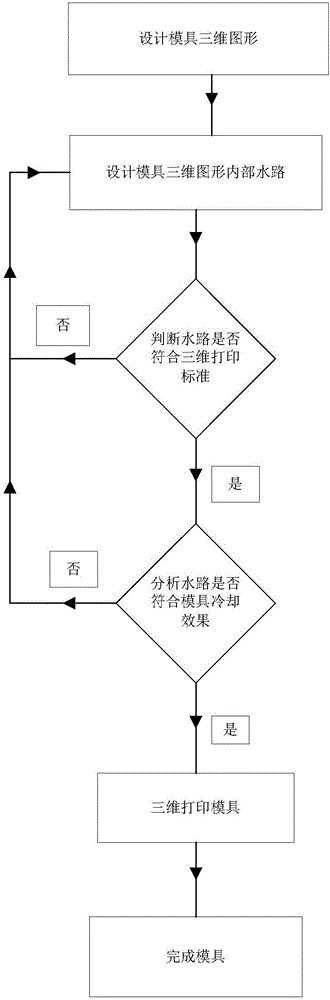

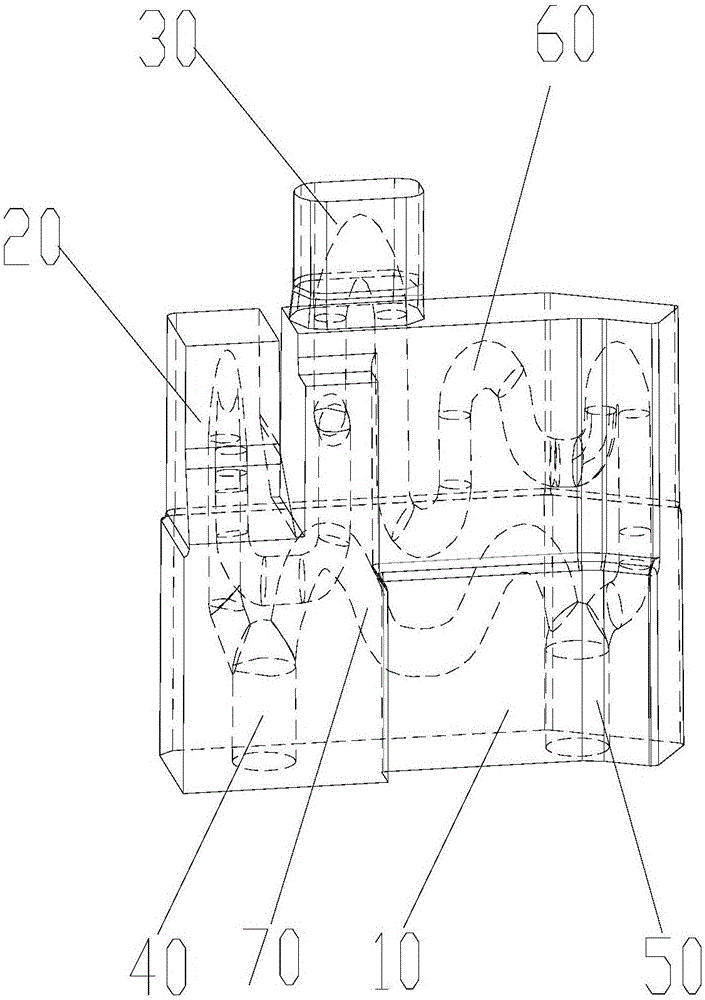

Mold manufacturing method based on three-dimensional printing

InactiveCN105082483AShorten the processing cycleReduce processing riskBiomedical engineeringComplex problems

The invention provides a mold manufacturing method based on three-dimensional printing. The mold manufacturing method based on three-dimensional printing is characterized by comprising the following steps of designing a three-dimensional mold figure; designing a water channel inside the three-dimensional mold figure; judging whether the water channel meets the standard of three-dimensional printing, if not, returning to the step of designing the water channel inside the three-dimensional mold figure to design the water channel again, and if yes, continuing the follow-up steps; analyzing whether the water channel meets the request for the cooling effect of a mold, if not, returning to the step of designing the water channel inside the three-dimensional mold figure, and if yes, continuing the follow-up steps; and printing the mold figure through a three-dimensional printer to form a mold. The mold manufacturing method based on three-dimensional printing can solve the design problem that a water channel of a traditional mold has poor the cooling effect, and can also solve the problem that traditional mold machining is long in period and complex in technological process.

Owner:BEIJING UREAL 3D TECH CO LTD

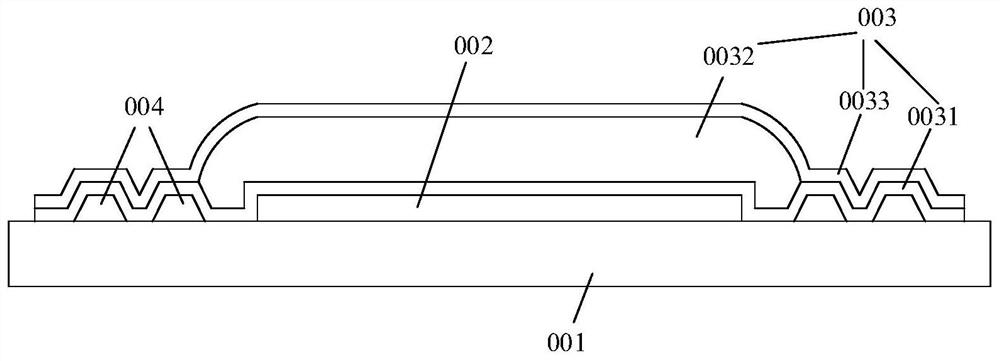

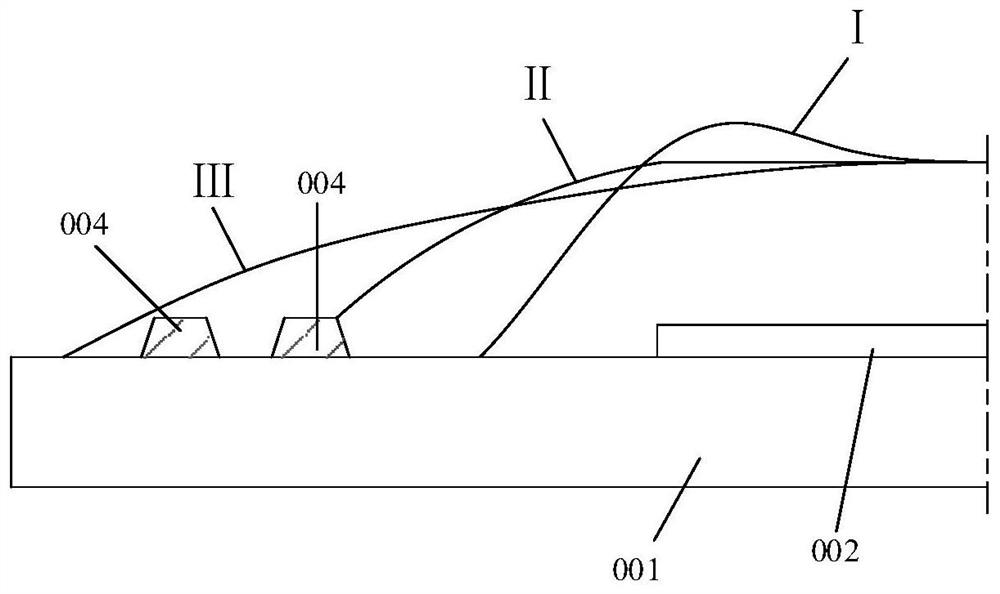

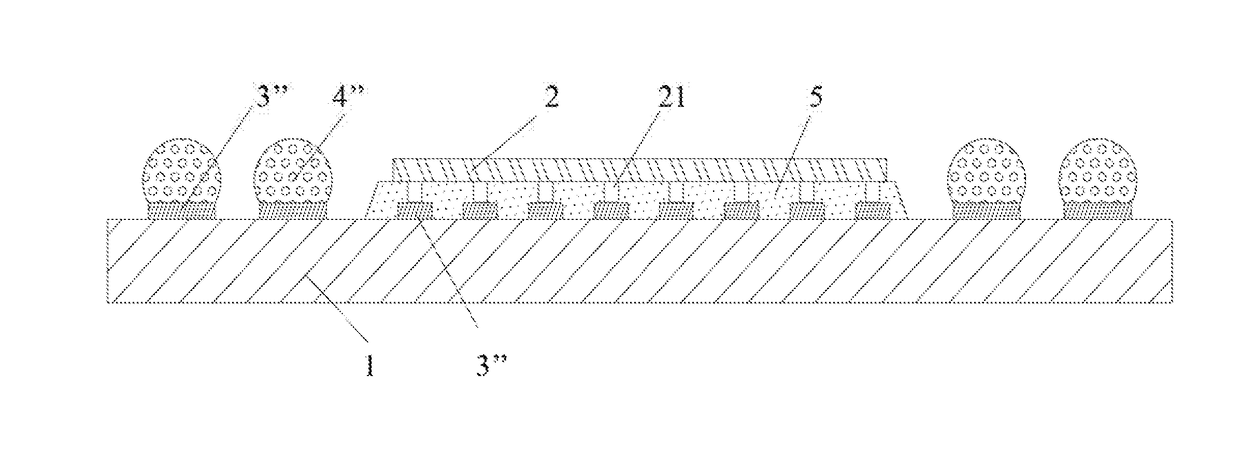

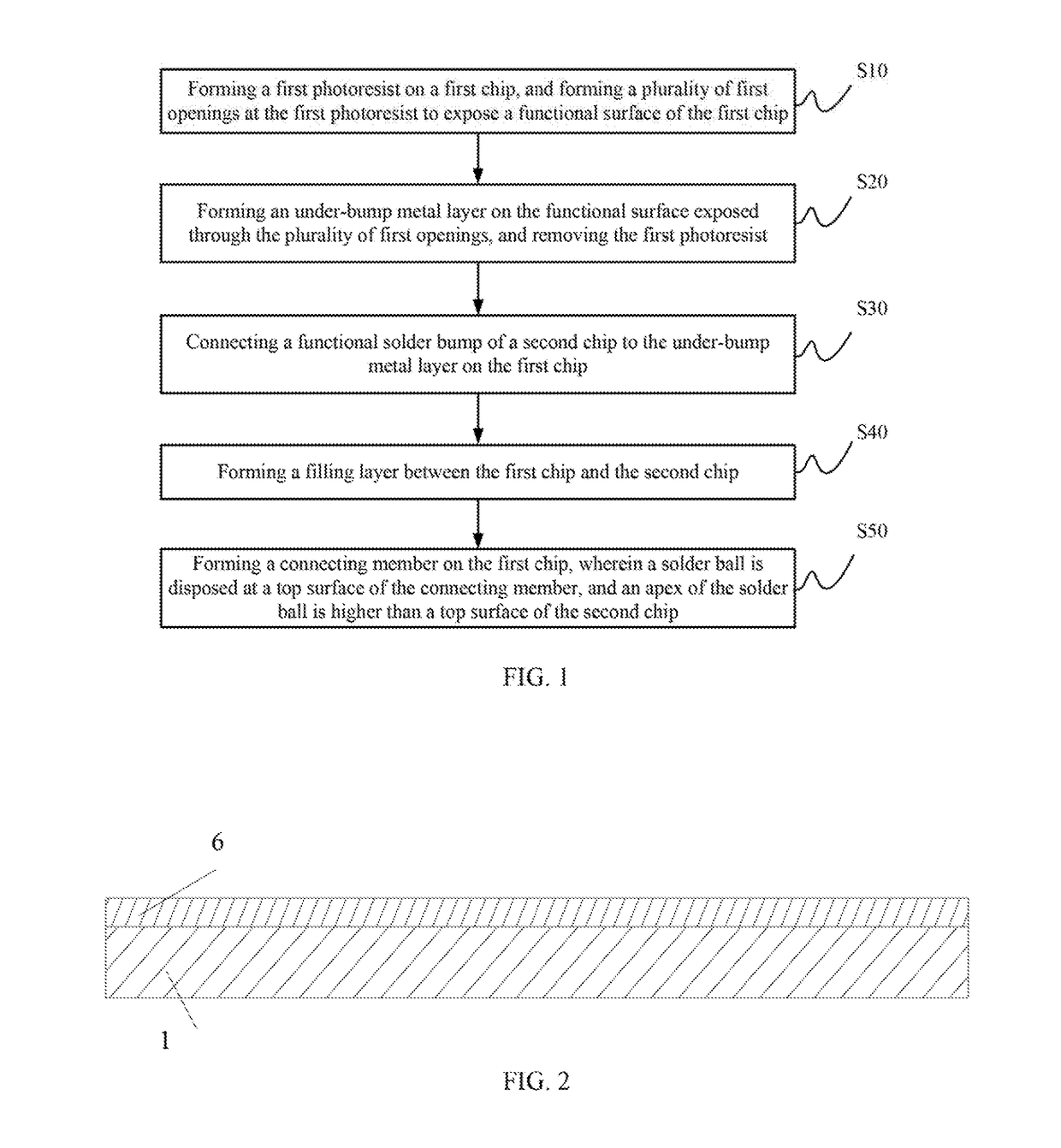

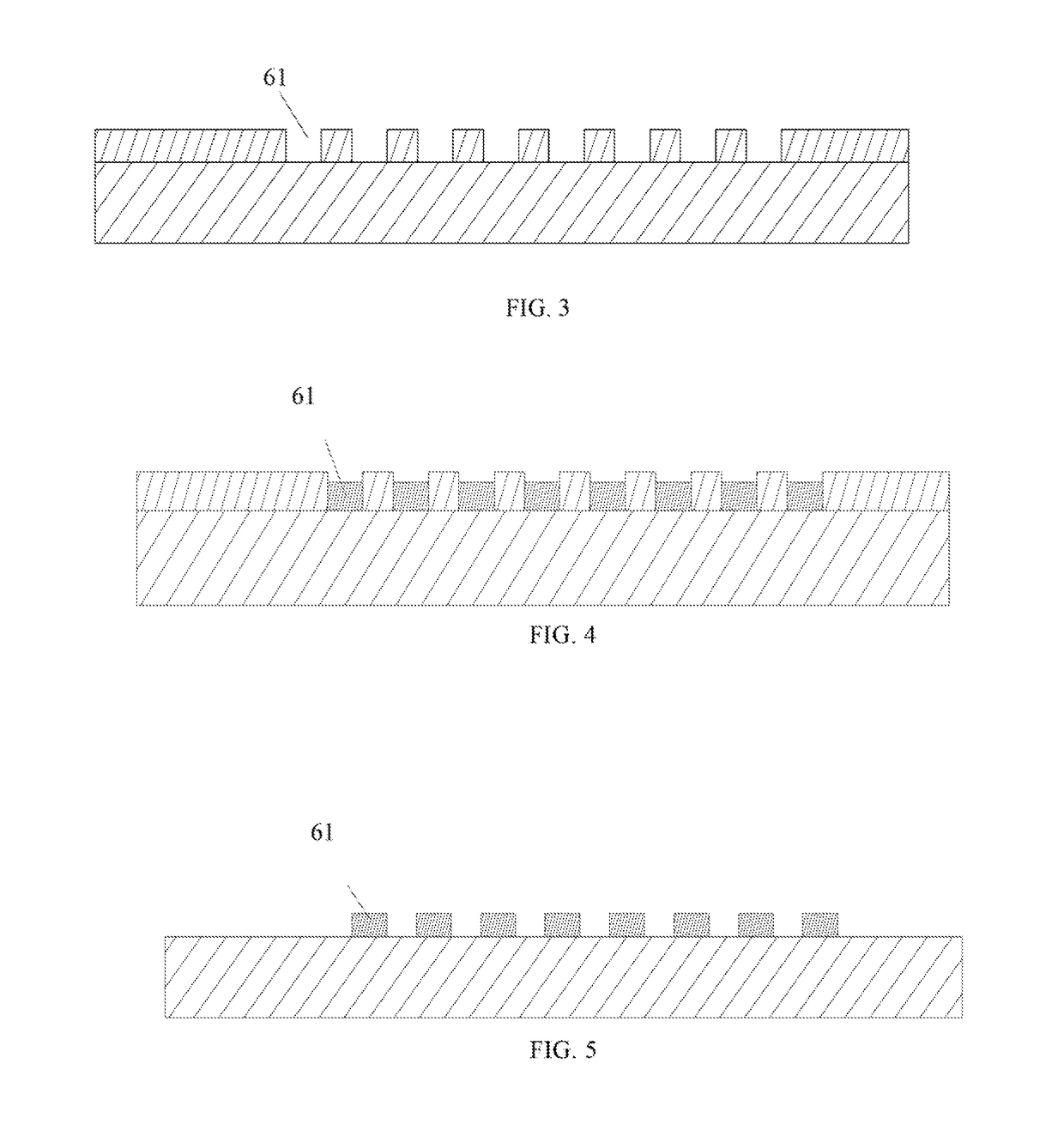

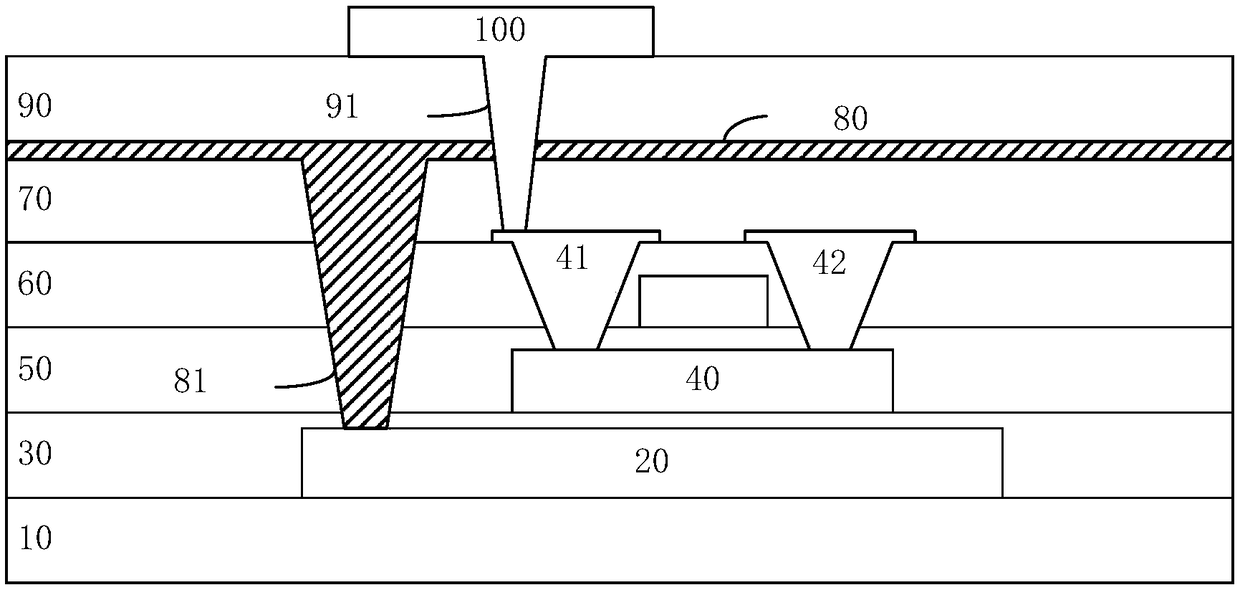

Fabricating method for wafer-level packaging

ActiveUS20170213810A1Reduce Process RiskReduce thicknessSemiconductor/solid-state device detailsSolid-state devicesPhotoresistWafer-level packaging

The present disclosure discloses a fabrication method for wafer-level packaging, comprising: forming a first photoresist on a first chip and a plurality of first openings at the first photoresist to expose a functional surface of the first chip, forming an under-bump metal layer on the functional surface exposed through the plurality of first openings, and removing the first photoresist; connecting a functional solder bump of a second chip to the under-bump metal layer on the first chip; forming a filling layer between the first chip and the second chip; and forming a connecting member on the first chip, wherein a solder ball is disposed at a top surface of the connecting member, and an apex of the solder ball is higher than a top surface of the second chip. The first chip and the second chip are disposed face-to-face, and the filling layer is formed between the first chip and the second chip. The solder ball is mounted on the connecting member. A certain height difference is formed between the solder ball and the second chip, such that a flip packaging of the chip is realized while the chip is not destroyed. The second chip will not be destroyed during the flip packaging, thereby reducing the processing risks.

Owner:NANTONG FUJITSU MICROELECTRONICS

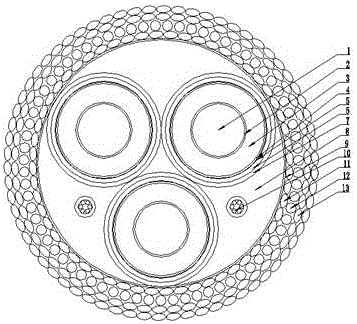

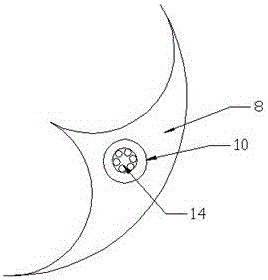

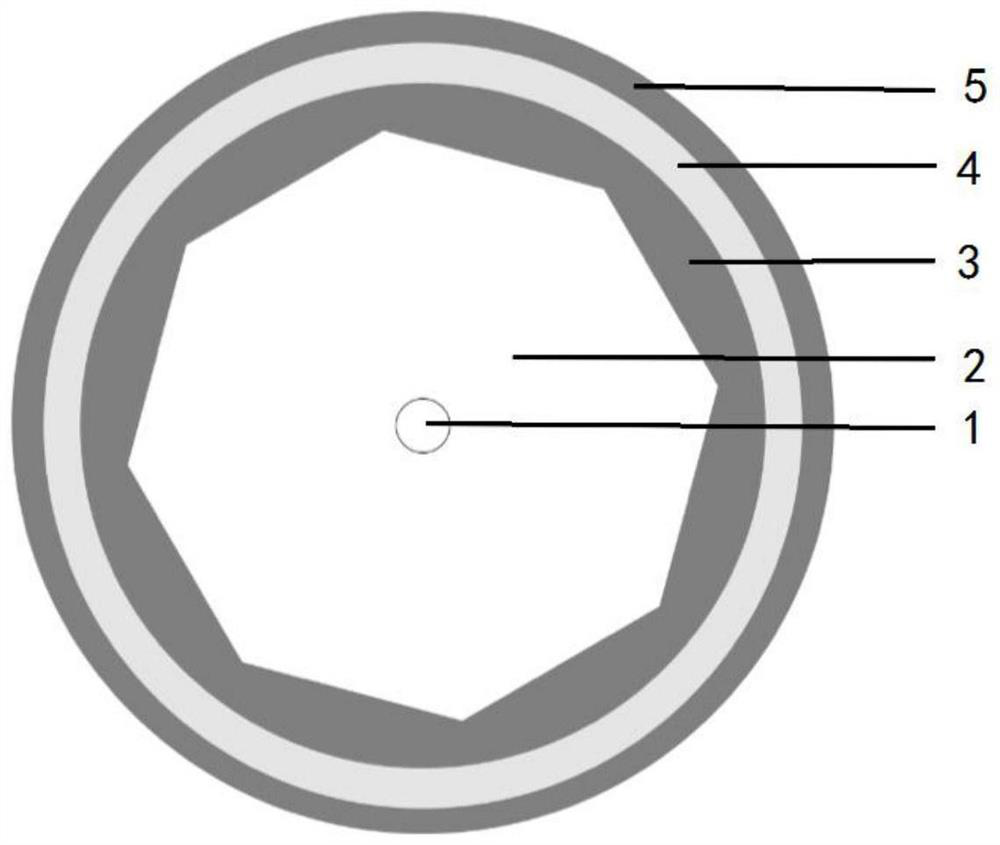

Cross-linked-polyethylene insulating optical-fiber composite three-core submarine power cable

InactiveCN105913966ASimple structureReasonable designInsulated cablesCommunication cablesCross-linked polyethyleneSubmarine power cable

The invention discloses a cross-linked-polyethylene insulating optical-fiber composite submarine power cable. The cable comprises a cable core, an optical unit, a reinforced filling strip, a wrapping tape, an inside liner, an armor layer and an outer covering layer, wherein the wrapping tape, the inside liner, the armor layer and the outer covering layer successively wrap outer sides of the cable core, the optical unit and the reinforced filling strip. The reinforced filling strip is filled in a cable core gap of an inner side of the wrapping tape and is provided with a preformed hole. The optical unit is placed in the preformed hole. By using the cross-linked-polyethylene insulating optical-fiber composite submarine power cable of the invention, the structure is simple; the design is reasonable; the reinforced filling strip is filled in the cable core gap and the optical unit is placed in the preformed hole of the reinforced filling strip so that on one hand, effects of protecting and fixing the optical unit are achieved, the optical unit can be prevented from being damaged during a laying process and a processing risk is reduced; and on the other hand, a degree of density and a spherical degree of a cabling product are increased.

Owner:HENGTONG SUBMARINE POWER CABLE CO LTD

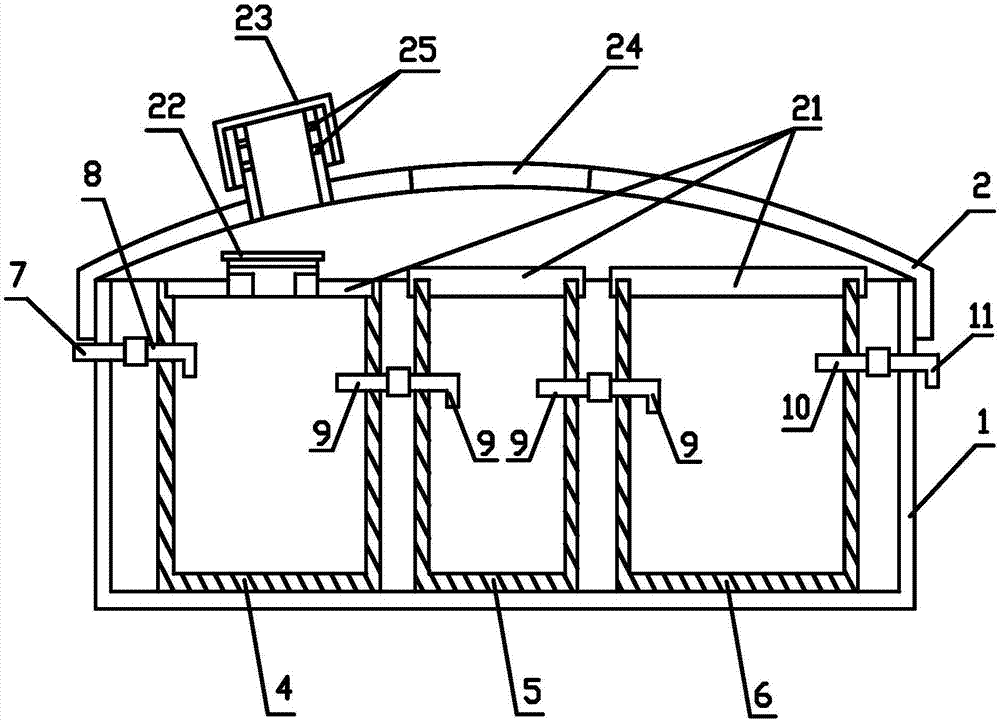

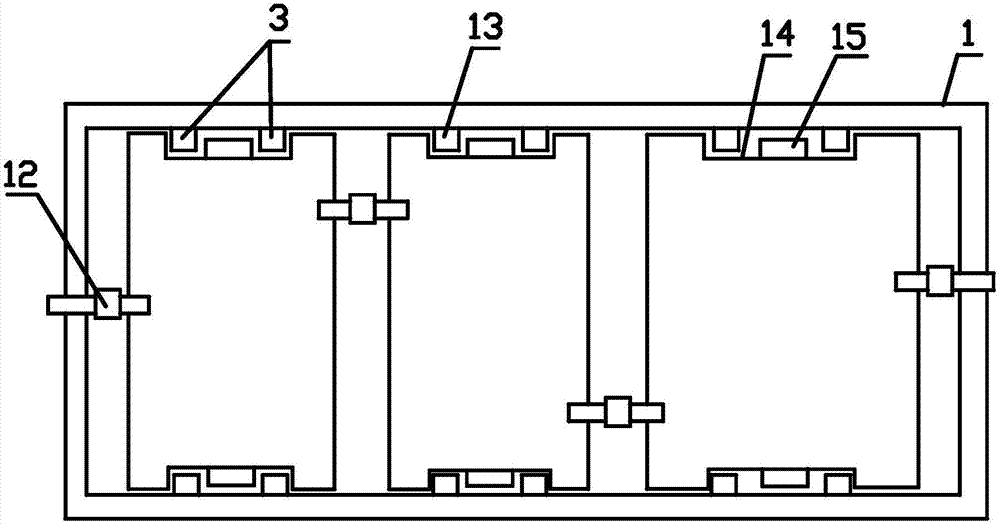

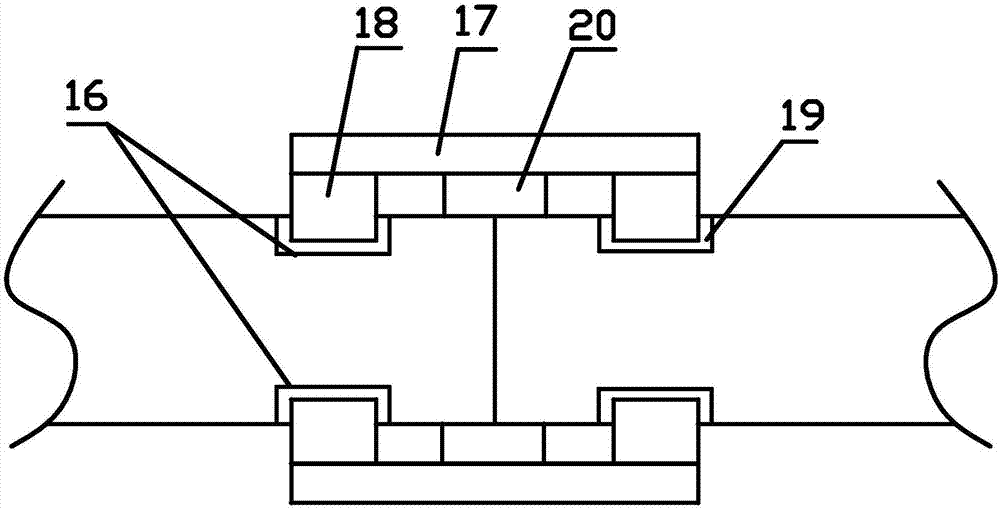

Integrated rural domestic wastewater treatment system

PendingCN107253760AGood leakproofEasy to installTreatment with anaerobic digestion processesBiological sludge treatmentWastewaterSewage

The invention discloses an integrated rural domestic wastewater treatment system. The integrated rural domestic wastewater treatment system comprises a fixing groove and a top cover formed in an opening end of the fixing groove; a fermenting tank, a manure through tank and a manure storage tank; a first-level water inlet pipe is arranged on the side wall of the fixing groove, a second-level water inlet pipe is arranged on the side wall of the fermenting tank, conduits are arranged on the opposite side walls between the fermenting tank and the manure through tank and on the opposite side walls between the manure through tank and the manure storage tank, a first-level drain pipe is further arranged on the side wall of the manure storage tank, a second-level drain pipe is arranged on the side wall of the fixing tank opposite to the manure storage tank, and the first-level water inlet pipe and the second-level water inlet pipe, the conduit of the fermenting tank and the conduit of the manure through tank, the conduit of the manure through tank and the conduit of the manure storage tank, and the first-level drain pipe and the second-level drain pipe are respectively detachably connected through sealing connecting pipes. The integrated rural domestic wastewater treatment system is a septic tank combined by various function modules, is convenient to install and prevents seepage, the septic tank can be conveniently cleaned by staff, and the processing risk is reduced.

Owner:李华

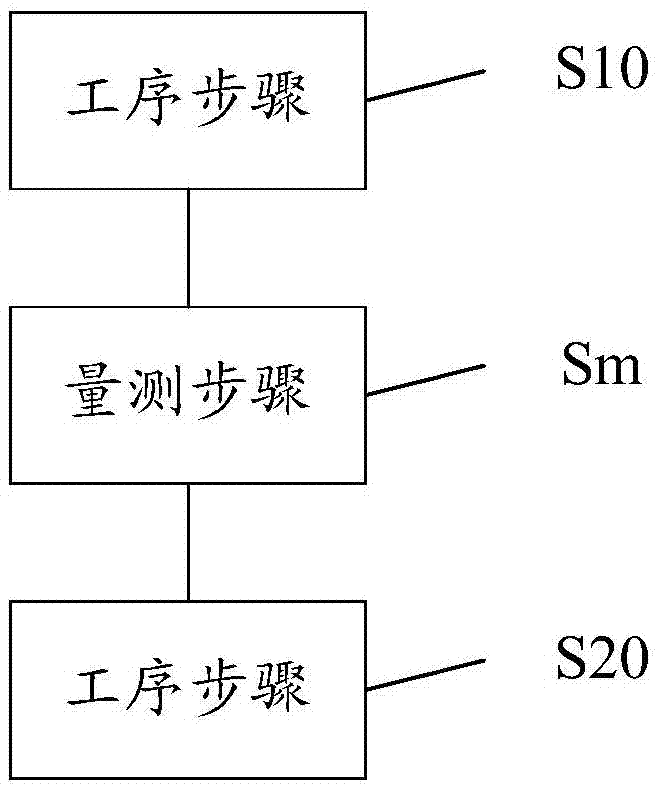

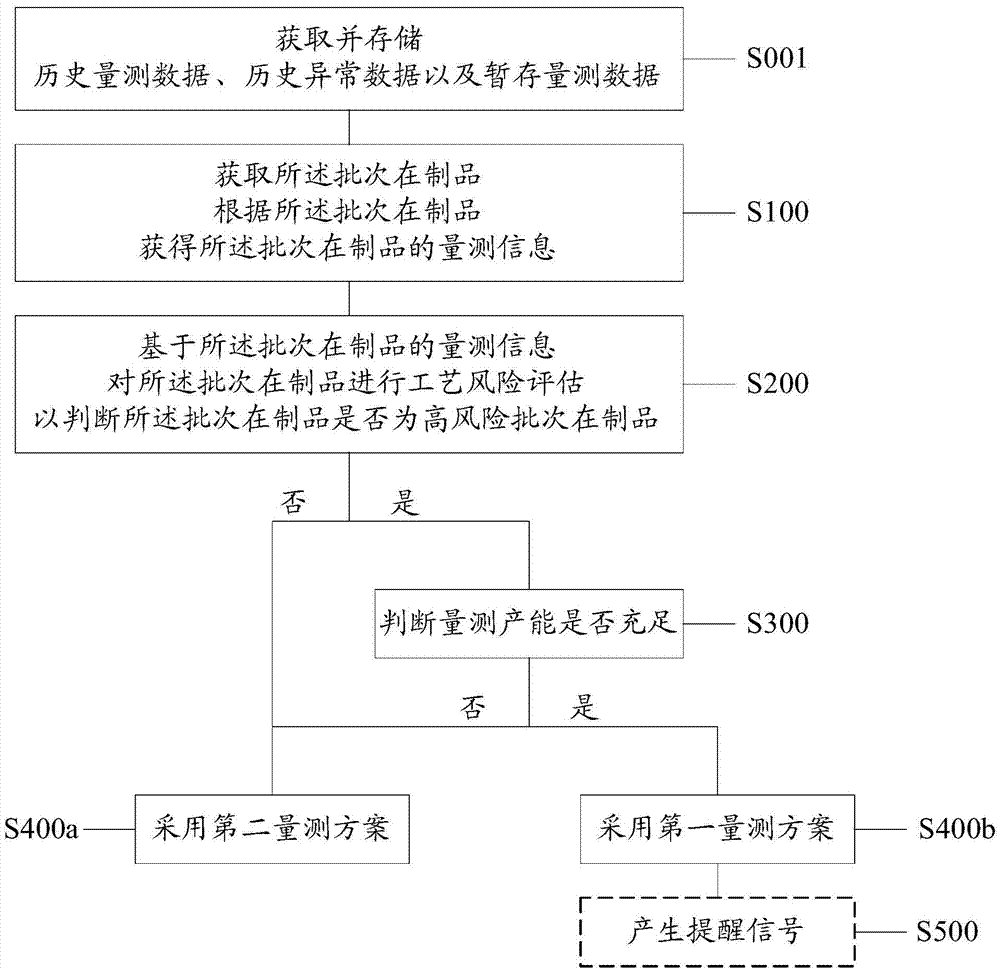

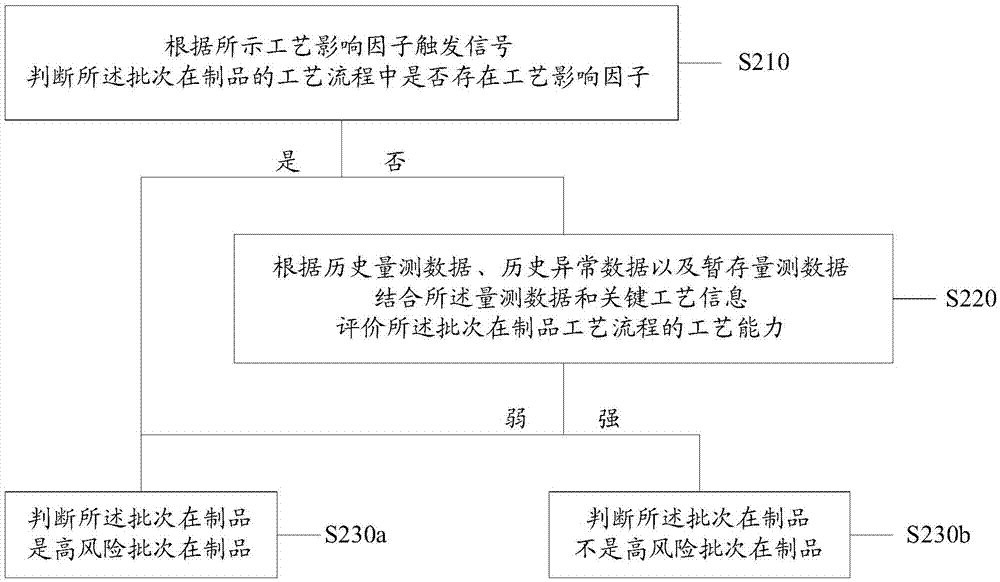

Sampling measurement system and sampling measurement method

ActiveCN106952842AKeep abreast ofTimely Workmanship PerformanceSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingRisk levelComputer science

The invention relates to a sampling measurement system and a sampling measurement method. By setting a first measurement scheme and a second measurement scheme in advance, the sampling rate of the first measurement scheme is larger than the sampling rate of the second measurement scheme, the first measurement scheme with relatively large sampling rate is employed when a batch product in production is judged to be a high-risk batch product in production and the measurement yield is judged to be enough, the process expression can be timely understood, the scrap rate of the product is reduced, and the manufacturing yield is improved; and the second measurement scheme with relatively small sampling rate is employed when the batch product in production is judged not to be the high-risk batch product in production or the measurement yield is judged not to be enough, so that the production period of the product is shortened. Therefore, the process risk estimation can be performed on the batch product in production based on the measurement information of the batch product in production, the measurement schemes with different sampling rates are selected to be employed according to the process risk level of the batch product in production, and the requirements that the production period of the product is shortened and the process expression is timely fed back can be compatible.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

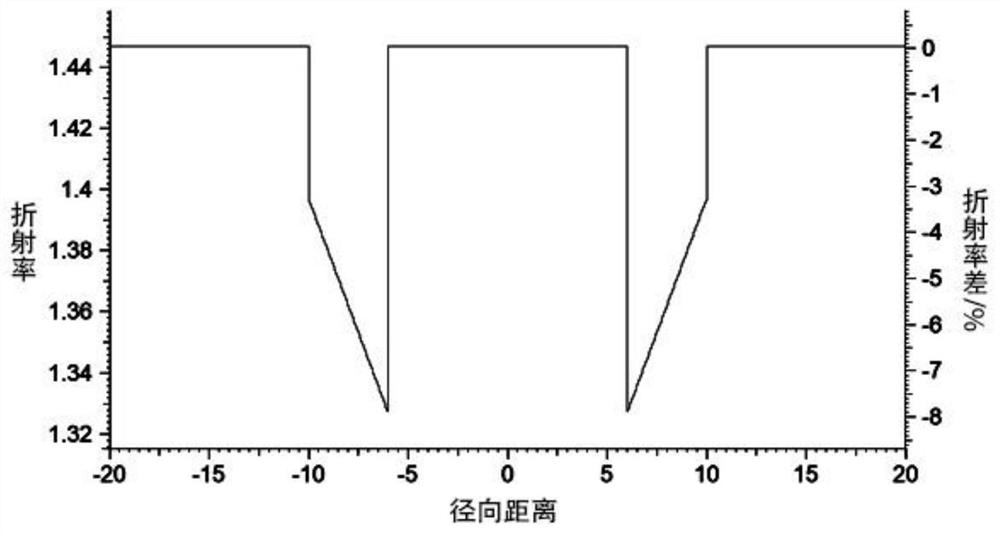

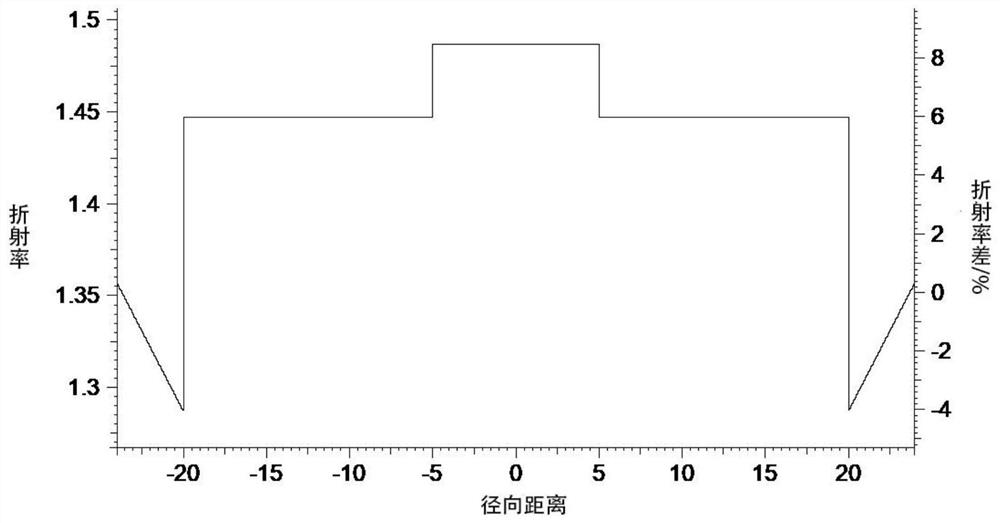

Hard cladding rare-earth-doped optical fiber and preparation method thereof

PendingCN112764155AMeet light limit requirementsReduce manufacturing difficultyGlass optical fibreGlass making apparatusHigh concentrationRare earth ions

The invention relates to a hard cladding rare-earth-doped optical fiber and a preparation method thereof. The hard cladding rare-earth-doped optical fiber comprises a core layer, a quartz cladding and a fluorine-doped cladding which are arranged from inside to outside in the radial direction, wherein the core layer is doped with rare earth ions; and the refractive index of the fluorine-doped cladding is gradually increased from inside to outside in the radial direction. The part playing a light limiting role in the fluorine-doped quartz layer of the hard cladding optical fiber is mainly the part closest to the quartz cladding, so that in the embodiment, the fluorine-doped quartz layer is optimized, that is, the fluorine-doped cladding is designed into a form that the refractive index of the fluorine-doped cladding is gradually increased from inside to outside in the radial direction, and during manufacturing, high-concentration doping is carried out on the innermost side to ensure that the fluorine doping concentration meets the requirement, so that the light limiting requirement of the optical fiber can be met, and meanwhile, the fluorine doping amount is gradually reduced towards the outer side instead of carrying out high-concentration doping on the whole fluorine-doped cladding, so that the manufacturing difficulty of the fluorine-doped tube can be reduced.

Owner:FENGHUO COMM SCI & TECH CO LTD +1

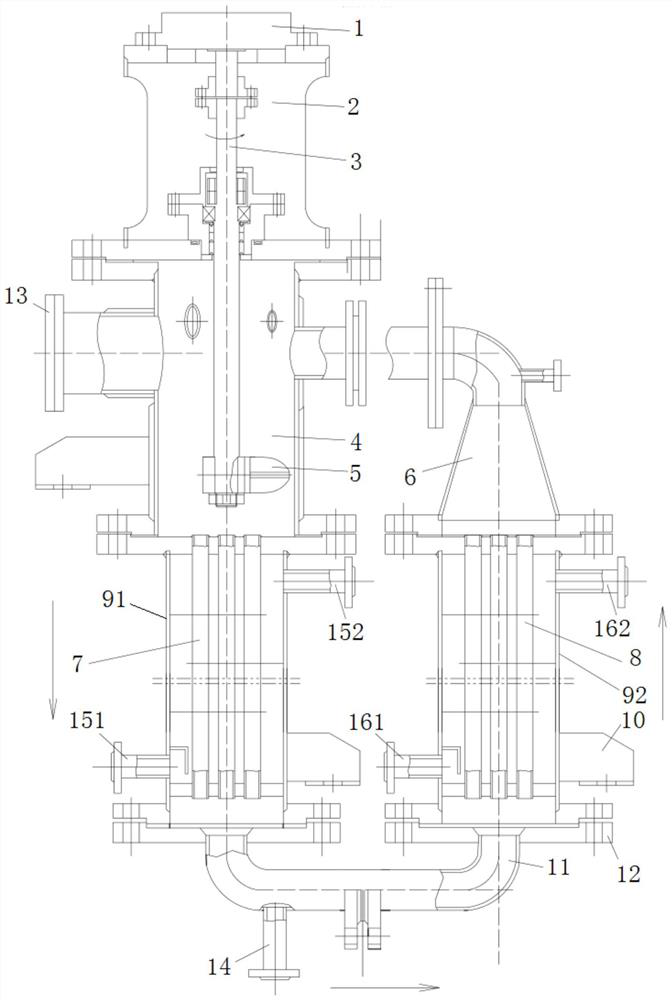

Self-powered continuous nitration method and device

ActiveCN113121356AShort stayReduced risk of thermal runawayOrganic compound preparationChemical/physical/physico-chemical stationary reactorsChemical industryOrganic synthesis

The invention belongs to the technical field of organic synthesis application, and particularly relates to a self-powered continuous nitration method and device. According to the method, a raw material (or a raw material solution) and mixed acid (or nitric acid) are added into a self-powered continuous reactor at the same time, reaction feed liquid continuously and circularly flows, is mixed and reacts in a tube pass through self-propelling force generated by stirring of an impeller, the mass and heat transfer process is completed, and the target requirement is met. According to the invention, the mass transfer and heat transfer efficiency can be improved, the heat exchange and heat transfer capabilities are improved, the reaction time is shortened, the risk degree of art is reduced, the thermal runaway risk is avoided, the reaction safety is improved, and the realization of chemical industry intrinsic safety large scale production is facilitated.

Owner:SHENYANG RES INST OF CHEM IND

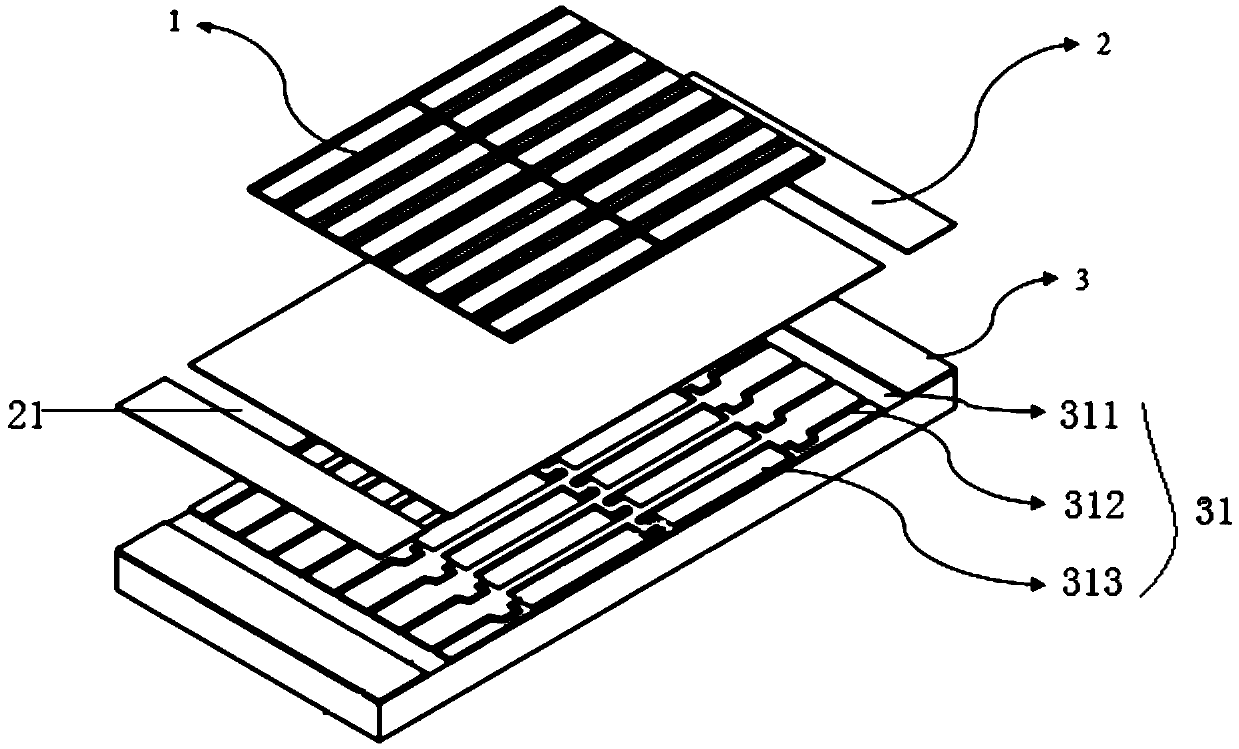

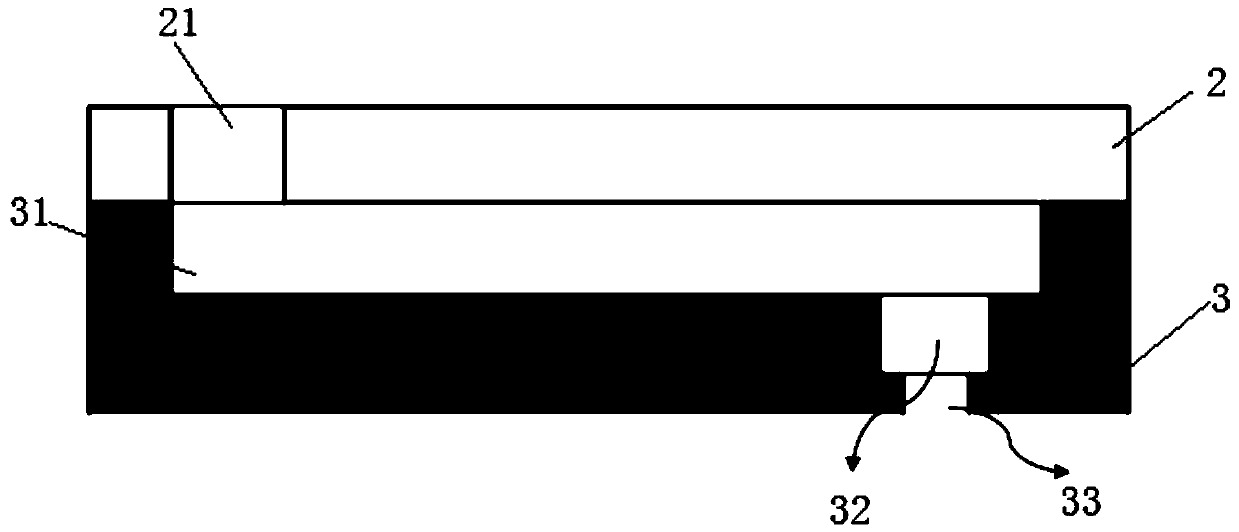

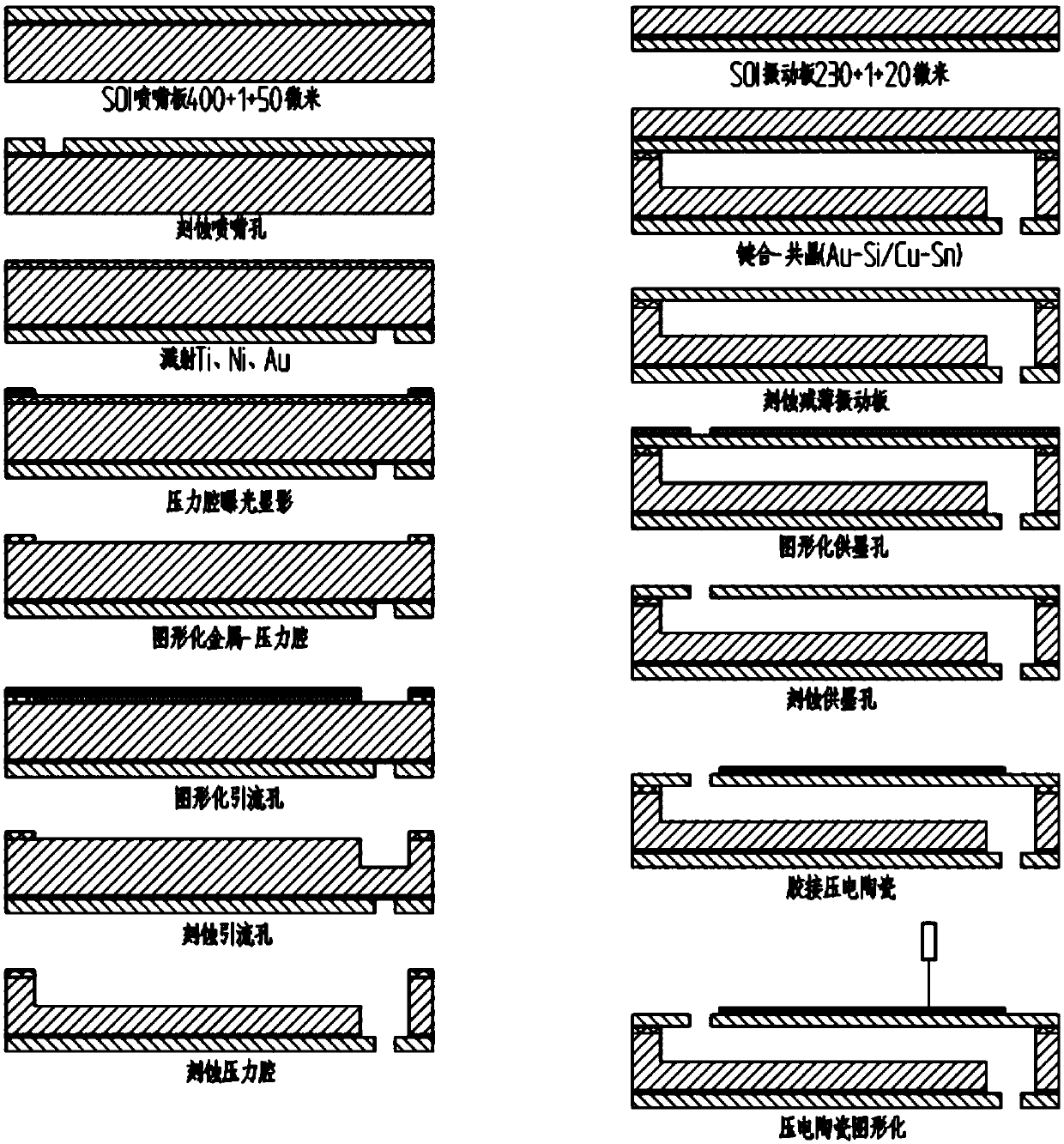

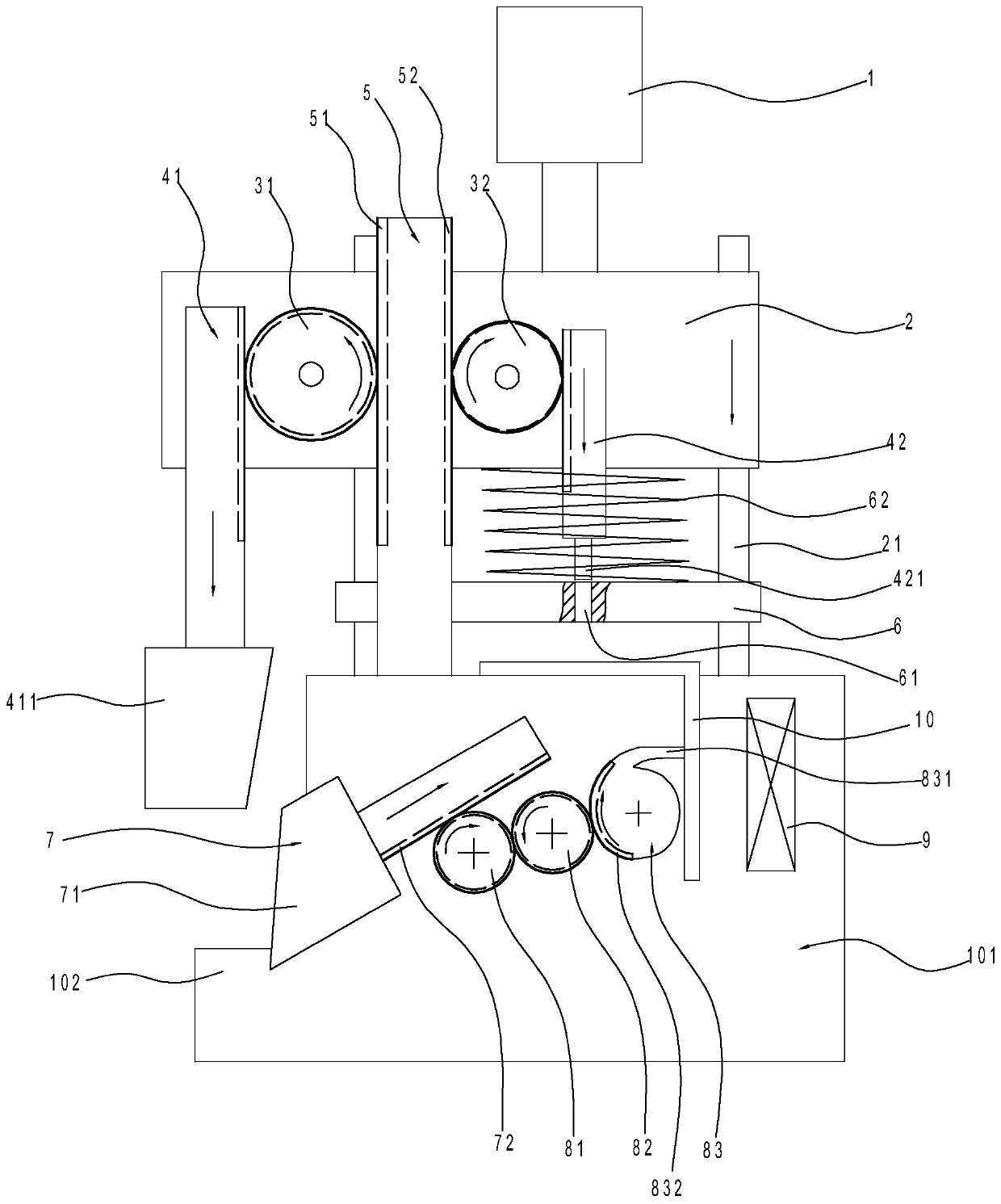

Piezoelectric MEMS ink-jet printing head and manufacturing method

ActiveCN111216452AReduce Process RiskImprove spraying effectInking apparatusPiezoelectric memsThin membrane

The invention relates to a piezoelectric MEMS ink-jet printing head and a manufacturing method. An SOI silicon wafer is used as a processing raw material of a vibration plate and a nozzle plate; structures of a pressure cavity, a drainage hole and a nozzle hole of the printing head are all integrally designed on the nozzle plate; a metal thin film layer is manufactured before the pressure cavity is manufactured, and the metal thin film layer is used as a masking layer for ICP dry etching of the pressure cavity; in addition, the masking layer serves as a bonding metal layer when the vibration plate and the nozzle plate are bonded in the later period. Compared with the existing manufacturing method of the MEMS ink-jet printing head, the manufacturing method of the piezoelectric MEMS ink-jetprinting head has the advantages of fewer overall process steps, fewer related process types, higher dimensional accuracy and higher efficiency, the technical problems that an existing piezoelectric MEMS ink-jet printing head manufacturing method relates to a large number of process types, the quality of a vibration plate is difficult to guarantee, and potential risks generated by bonding are large are solved.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN

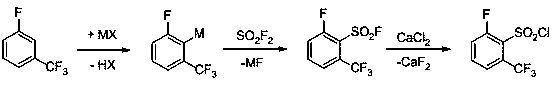

Preparation method of 2-fluoro-6-trifluoromethylbenzenesulfonylchloride

InactiveCN107935891AReduce Process RiskLithium organic compoundsSulfonic acid preparationBenzeneOrganic solvent

The invention provides a preparation method of 2-fluoro-6-trifluoromethylbenzenesulfonylchloride. The method comprises the following steps: reacting fluoro-3-benzene and alkali serving as main raw materials in an organic solvent to generate a corresponding salt; reacting the generated salt with sulfuryl fluoride under a certain pressure to generate 2-fluoro-6-trifluoromethanesulphonyl fluoride; reacting filtered and distilled reaction liquid with calcium chloride in a mixed solution; filtering, separating and desolventizing the reaction liquid to obtain liquid-state 2-fluoro-6-trifluoromethylbenzenesulfonylchloride of which the yield is 85 percent or more and the purity is 96 percent or more. The preparation method of the 2-fluoro-6-trifluoromethylbenzenesulfonylchloride provided by the invention has the advantages of no use of highly-toxic or poisonous gas, mild conditions, easiness in controlling, adoption of readily-available raw materials, lower cost, no three waste (waste water, waste solid and waste gas) discharge, and suitability for industrial production.

Owner:HANDAN ZHAODU FINE CHEM CO LTD

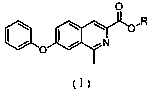

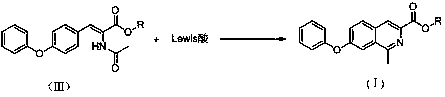

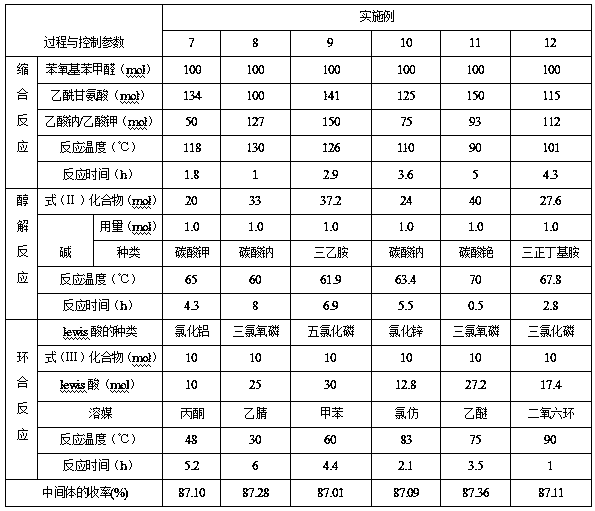

Roxadustat key intermediate and synthetic method thereof

ActiveCN109305940AReaction raw materials are readily availableReduce manufacturing costOrganic chemistrySodium acetateAlcohol

The invention discloses a Roxadustat key intermediate and a synthetic method thereof. The Roxadustat key intermediate is 1-methyl-7-phenoxyisoquinoline-3-carboxylate. The synthetic method for the Roxadustat key intermediate comprises the following three steps that firstly, 4-phenoxybenzaldehyde and N-acetylglycine are subjected to Erlenmeyer-Pl-chl condensation reaction in the presence of acetic anhydride and sodium acetate or potassium acetate, then alcoholysis reaction is carried out with alcohol in the presence of alkali, and finally, Bischler-Napieralski cyclization reaction is carried outwith leiws acid in the presence of a solvent so as to obtain the Roxadustat key intermediate. The synthetic method has the advantages that the raw materials are easy to obtain, the reaction conditions are mild, the requirement for equipment is low, the yield is high, the synthesis steps of Roxadustat are shortened, and the method is suitable for industrial production.

Owner:HEBEI DONGKANG BIOTECH CO LTD

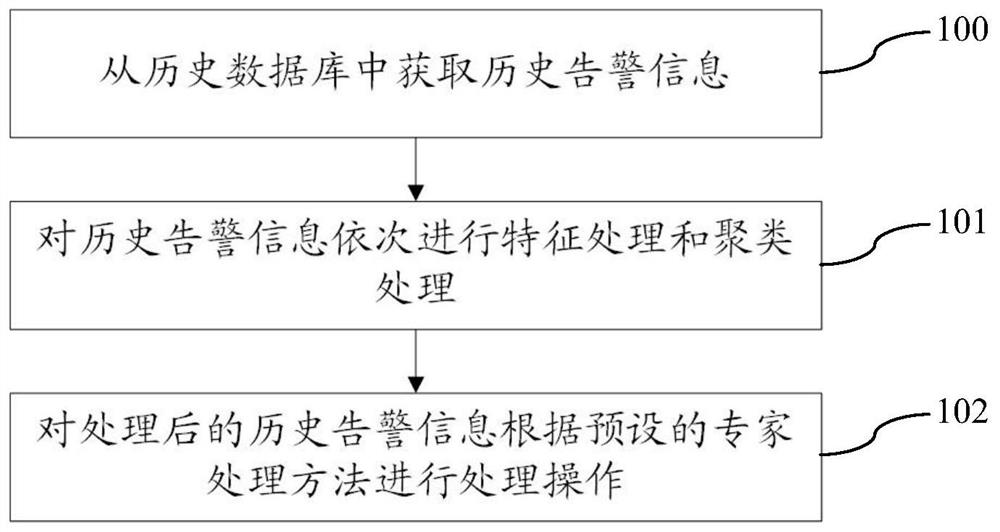

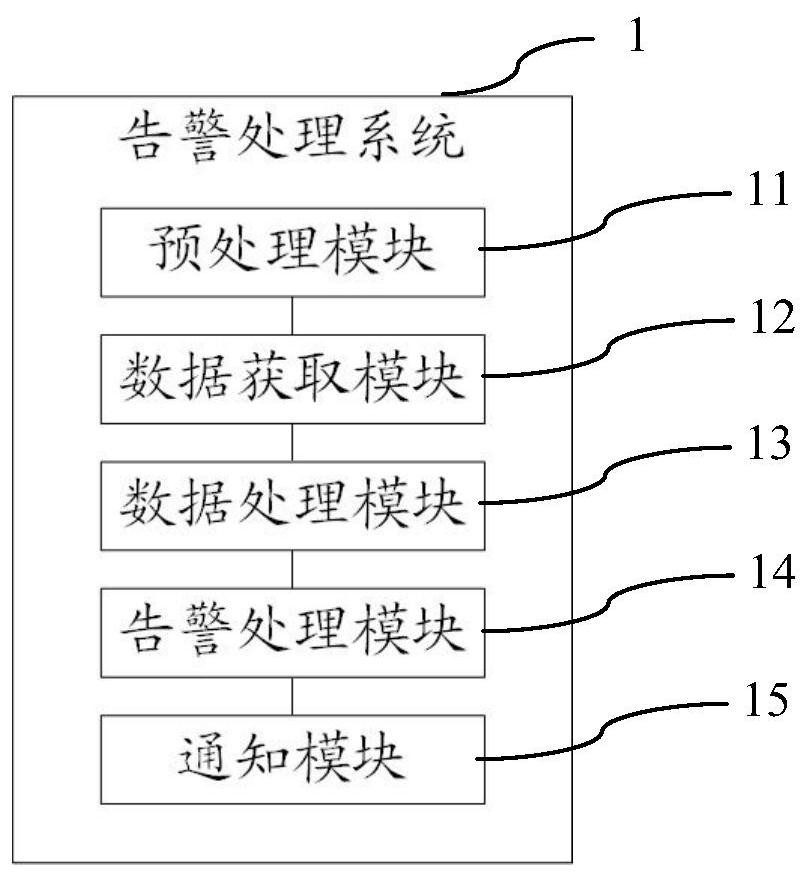

Alarm processing method, system and device and storage medium

ActiveCN112468339ARelieve pressureReduce processing dimensionalityData switching networksSpecial data processing applicationsFeature extractionDatabase

The invention provides an alarm processing method, system and device and a storage medium, and the method comprises the steps: obtaining historical alarm information from a historical database; sequentially carrying out feature processing and clustering processing on the historical alarm information; and processing the processed historical alarm information according to a preset expert processingmethod. According to the alarm processing method provided by the invention, the alarm is converged based on feature extraction and clustering, the processing dimension is reduced, and meanwhile, differences between manufacturers and systems are shielded through structured processing, clustering processing, classification processing and the like. In combination with domain expert operation and maintenance experience, intelligent alarm processing is realized, so that the fault processing efficiency is improved, and the pressure of operation and maintenance personnel is reduced. Besides, the method supports intelligent creation of ITSM event lists and change lists for various fault scenes and intelligent notification of related personnel so that the process risk can be reduced and audit can be avoided.

Owner:CHINA CONSTRUCTION BANK

Array substrate, display panel and electronic equipment

ActiveCN112198729AReduce depthImprove stabilityTransistorSolid-state devicesEngineeringMaterials science

The invention discloses an array substrate, a display panel and electronic equipment. The array substrate comprises a substrate which comprises a first conductive layer disposed on a third insulatinglayer; the first conductive layer comprises a first connecting part; the first connecting part is connected with a first metal part; a fourth insulator is arranged on the first conductive layer; a second via hole is formed in the fourth insulator; the second conducting layer is arranged on the fourth insulator and in the second via hole; the second conducting layer comprises a second electrode; the second electrode covers a PIN diode; and the second electrode is connected with the first connecting part through the second via hole. According to the array substrate, the display panel and the electronic equipment, the stability of an optical sensor can be improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Touch display panel and manufacturing method thereof

ActiveCN108447875ARealize the touch functionLow costSolid-state devicesSemiconductor/solid-state device manufacturingShielding blockMetal

The invention discloses a touch display panel and a manufacturing method thereof. The touch display panel comprises a substrate, a first metal layer, a TFT functional layer, and a common electrode layer, wherein the first metal layer comprises a touch line and light shielding blocks arranged on the substrate; the TFT functional layer is positioned on the first metal layer, and a first via hole isformed in the TFT functional layer; and the common electrode layer is positioned on the TFT functional layer and connected with the first via hole through the touch line. By virtue of the mode, the manufacturing cost can be lowered and the processing reliability can be improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

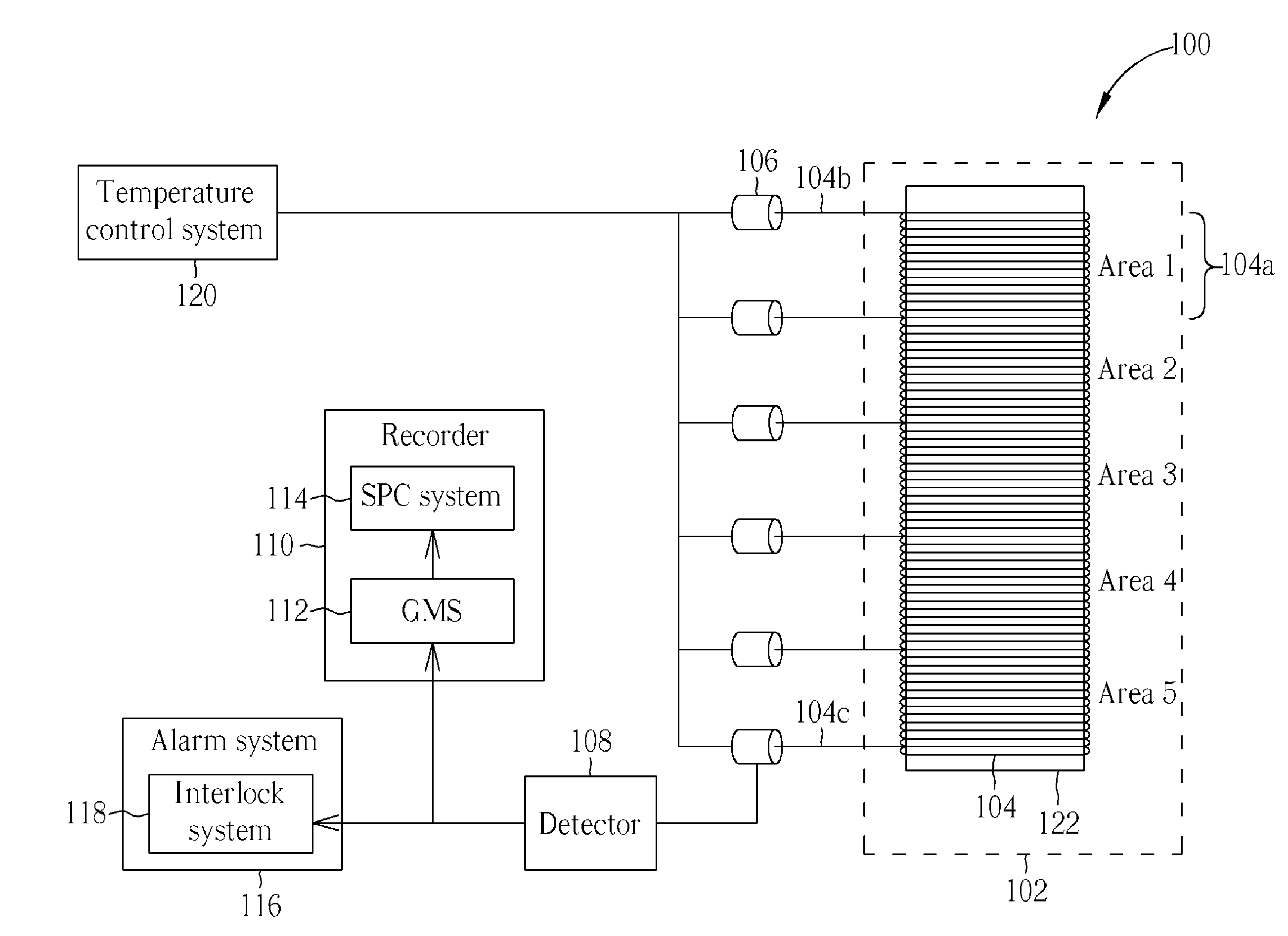

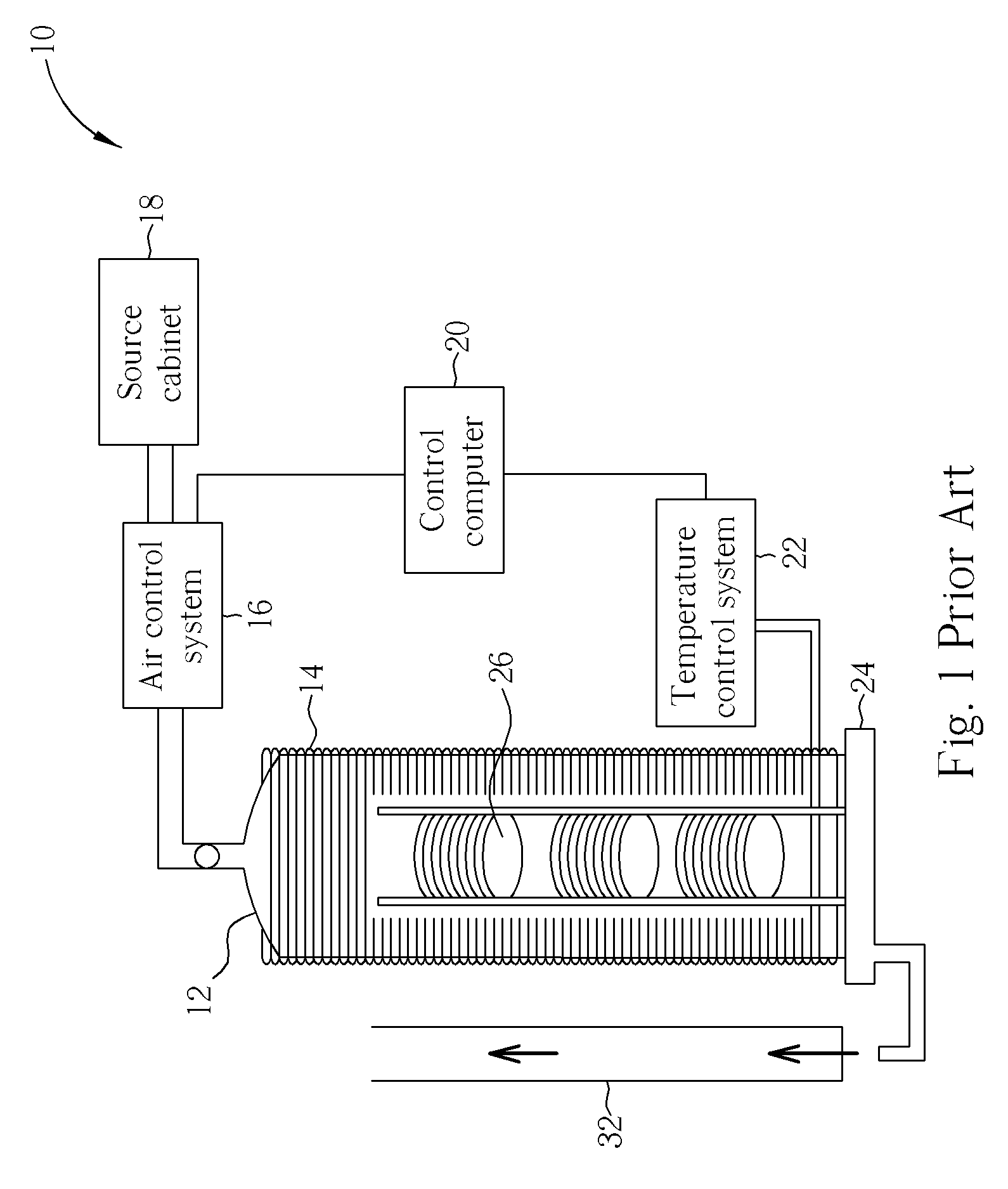

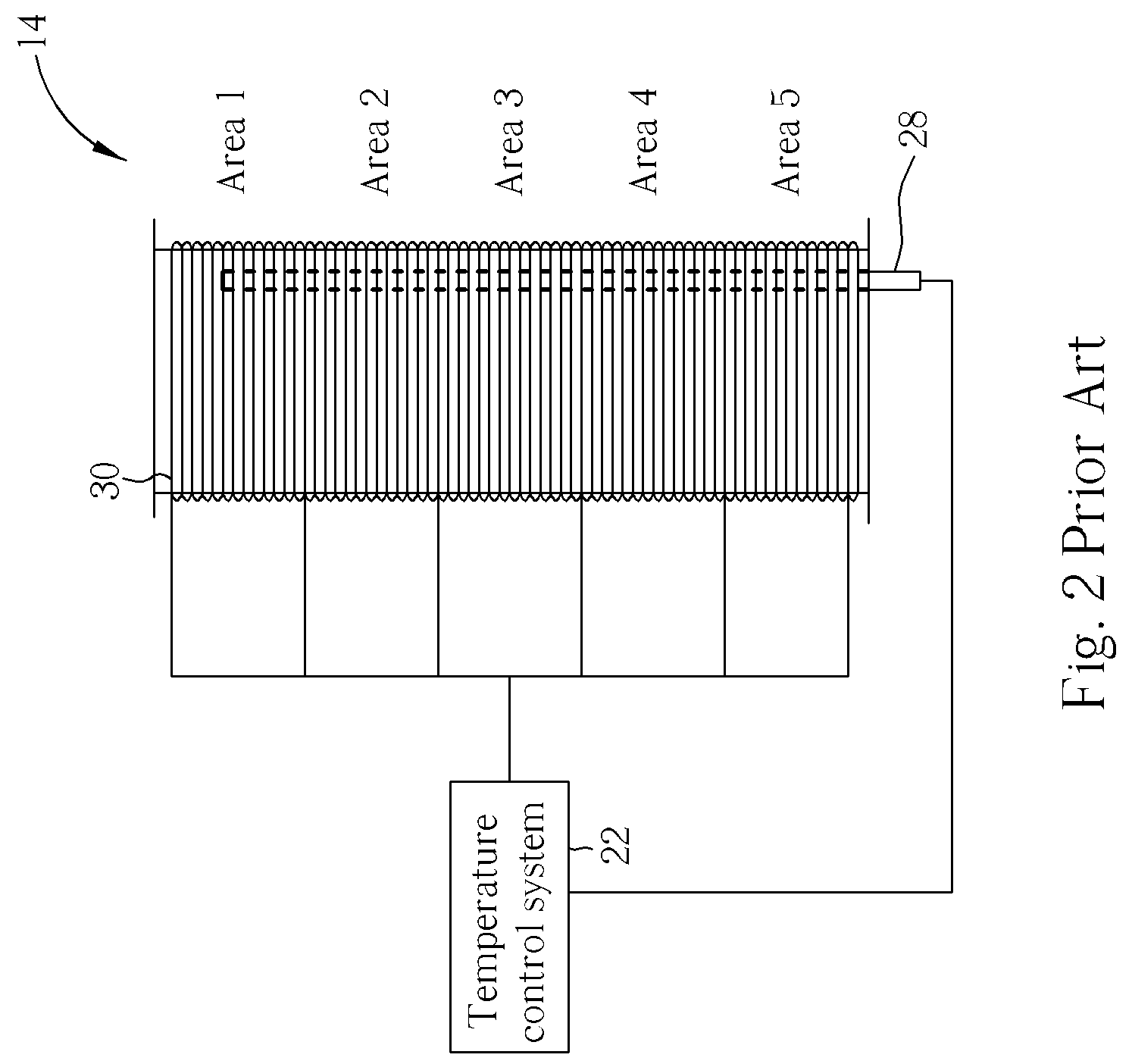

Semiconductor equipment and breakdown precautionary system and method thereof

InactiveUS20090039070A1Reduce Process RiskUndesirable costCharge supportsBaking ovenEngineeringFault prevention

A breakdown precautionary system of a semiconductor equipment includes a semiconductor equipment with a coil heater, at least a voltage / current detector, and an alarm system. The voltage / current detector detects the voltage and current of the coil heater at the same time. An alarm system will send an alarm signal and initiate an interlock safety measure of the semiconductor equipment when the detected current of the coil heater is 0 ampere.

Owner:UNITED MICROELECTRONICS CORP

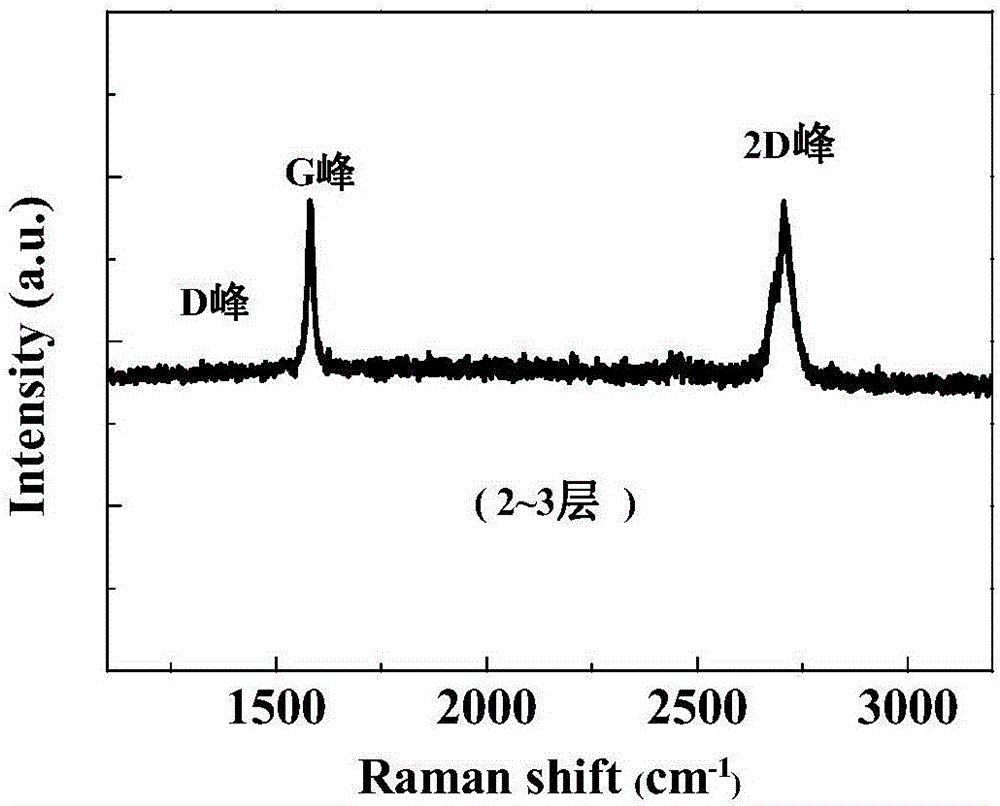

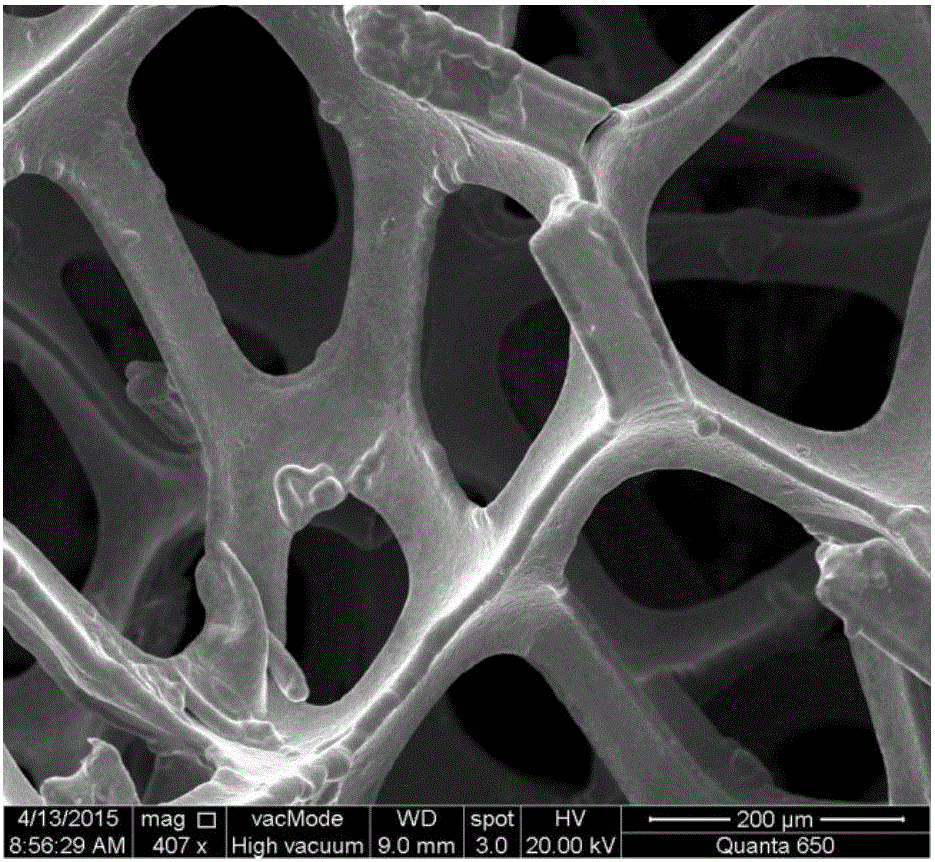

Direct preparation method of graphene/metal or alloy composite material

InactiveCN106087038AMeet application requirementsFast preparationPolycrystalline material growthFrom chemically reactive gasesAlloy substrateAlloy composite

The invention relates to a direct preparation method of a graphene / metal or alloy composite material. A cheap and easily available carbon source gas is adopted as a reaction raw material, active metal or alloy foil is adopted as a substrate, and graphene catalytically grows on the surface of the metal or alloy substrate through a CVD technology in reducing gas and protection atmosphere to prepare the graphene / metal (alloy) composite material through one step, so problems brought by routine synthesis, separation and transfer of graphene and a target material recompounding technology are solved, rapid preparation of the high-quality graphene / metal (alloy) composite material is realized, and requirements for graphene applied to parts of electronic devices and composite materials are met. The method has the advantages of simple process flow, low cost, controllable graphene layer number, elimination of destroys of the separation and transfer process to the quality of graphene, and reduction of the recompounding technology risk of graphene and metal (alloy).

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

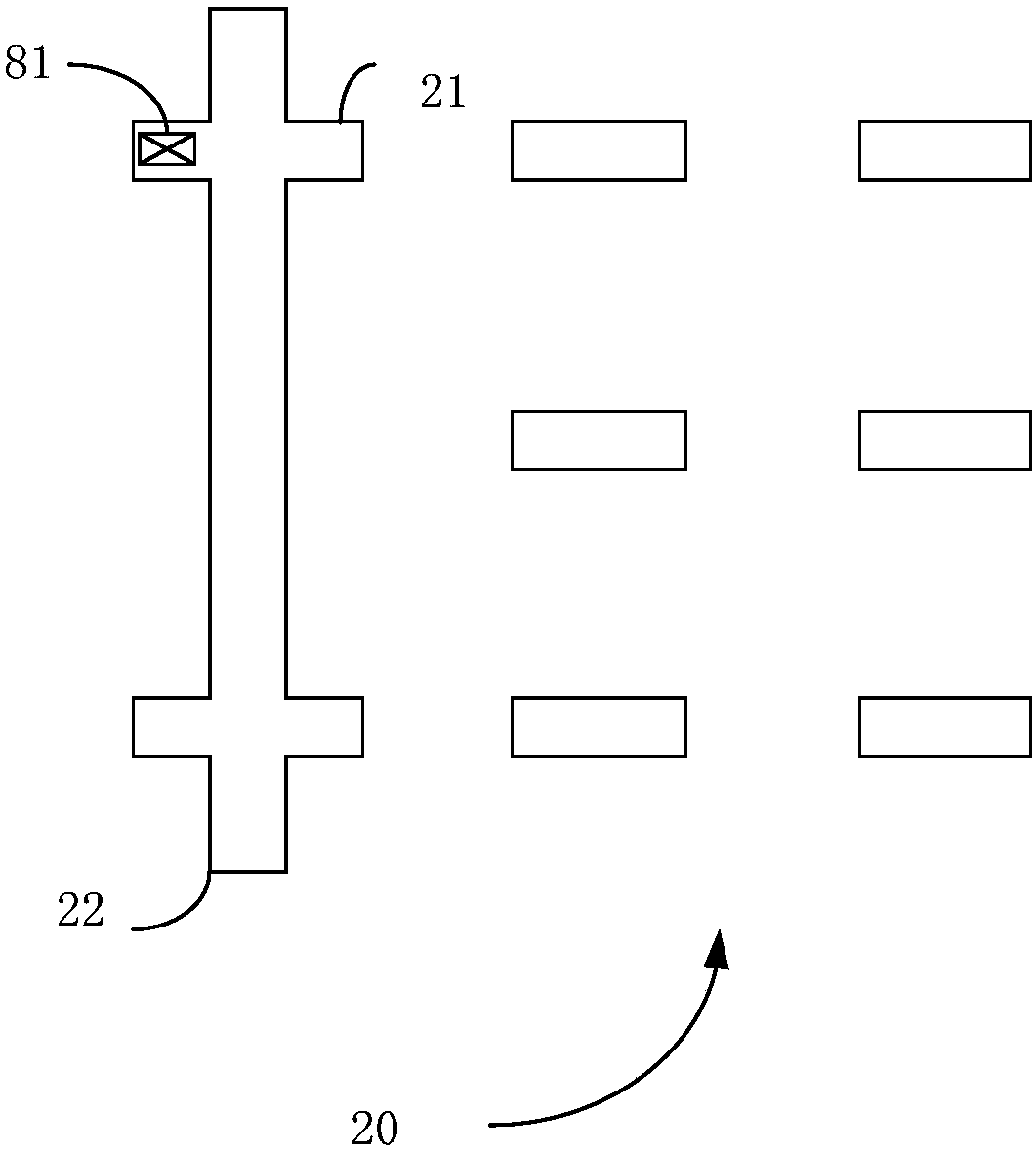

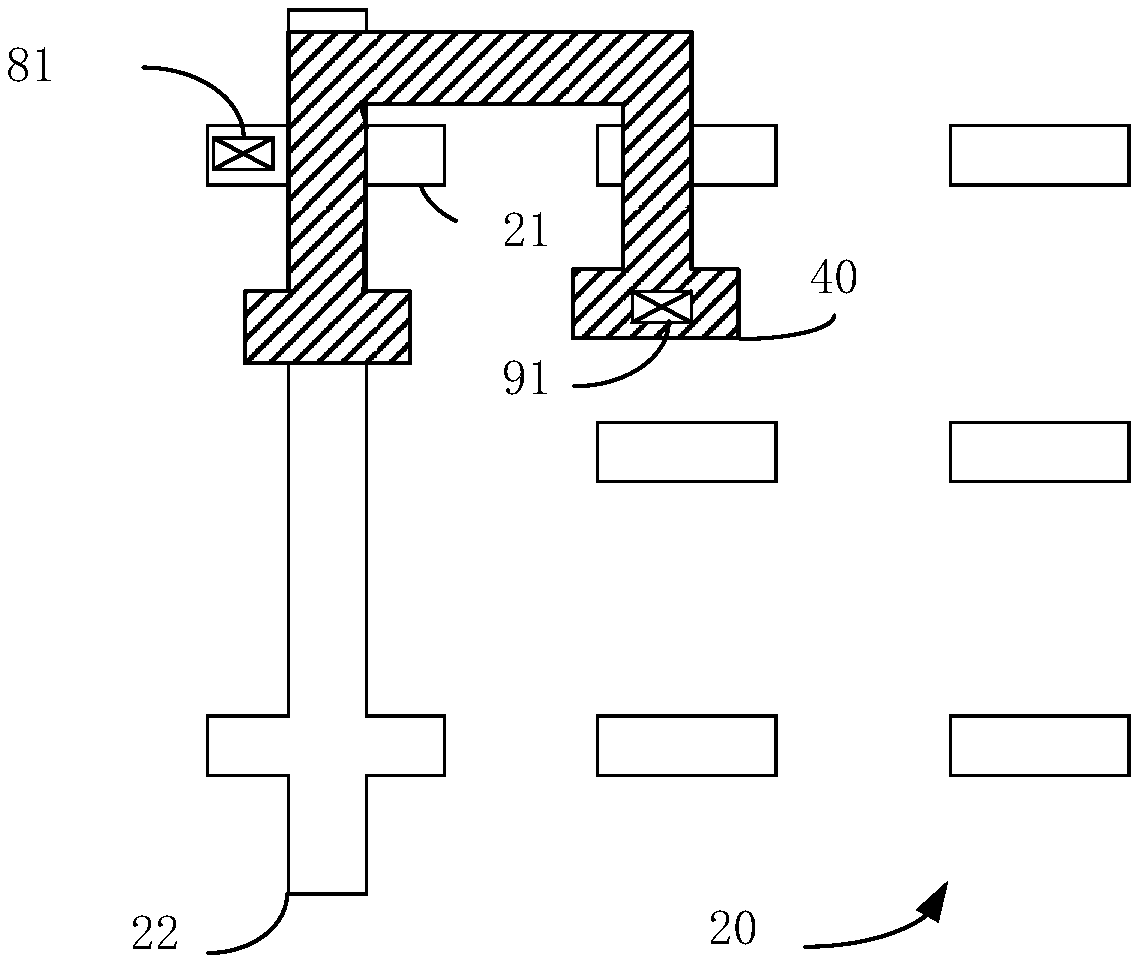

Array substrate and preparation method thereof and display panel

InactiveCN110828477AReduce Process RiskPreparation does not affectSolid-state devicesNon-linear opticsBottom gateMaterials science

The invention provides a TFT array substrate and a preparation method thereof and a display panel. The TFT array substrate is defined with a first area and a second area, a first TFT is arranged on the first area, and a second TFT is arranged on the second area. The first TFT is a top gate type TFT, the second TFT is a bottom gate type TFT, and the material adopted by a source-drain layer of the first TFT is consistent with the material adopted by a gate layer of the second TFT. The TFT array substrate provided by the invention is designed by adopting a novel film layer structure, so that thefirst TFT and the second TFT arranged on the TFT array substrate can be well compatible in design and manufacturing process, and the manufacturing process risk of the array substrate where the first TFT and the second TFT are located is reduced.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

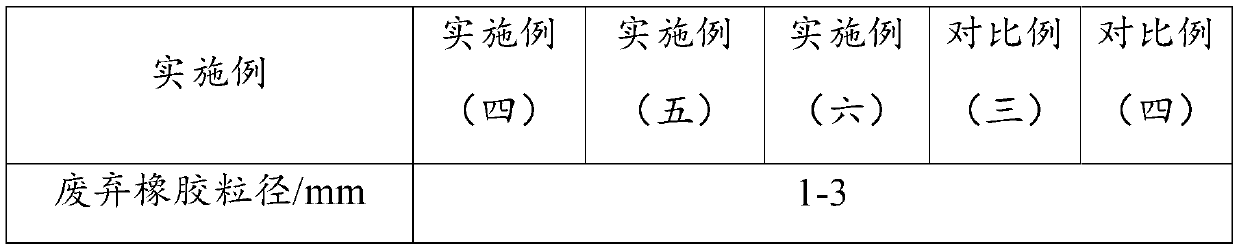

High-efficiency cracking recovery method for silicone rubber waste

ActiveCN111040243AReduce dosageImprove stabilitySilicon organic compoundsPlastic recyclingPolymer scienceDepolymerization

The invention relates to a cracking recovery method of silicone rubber waste. The method comprises the following steps: crushing of the silicone rubber waste; double cracking: putting crushed siliconerubber particles into a cracking reaction kettle, then adding a high-temperature-resistant inert solvent, alkali metal hydroxide and a Schiff base metal complex, and carrying out depolymerization ata high temperature of 140-200 DEG C in a nitrogen atmosphere to obtain crude DMC, wherein the usage amount of the alkali metal hydroxide is 5-8% of the weight of the silicone rubber waste; polymerizing and rearranging; and decolorizing and deodorizing, thereby obtaining the refined cyclosiloxane DMC. According to the cracking recovery method of the silicone rubber waste, double cracking and polymerizing and rearranging are organically combined and reasonably arranged, so the method has the advantages of low use of basic catalyst in recovery, high waste silicone rubber recovery efficiency, litter generated waste and accordance with circular economy.

Owner:GUANGZHOU BAIYUN CHEM IND

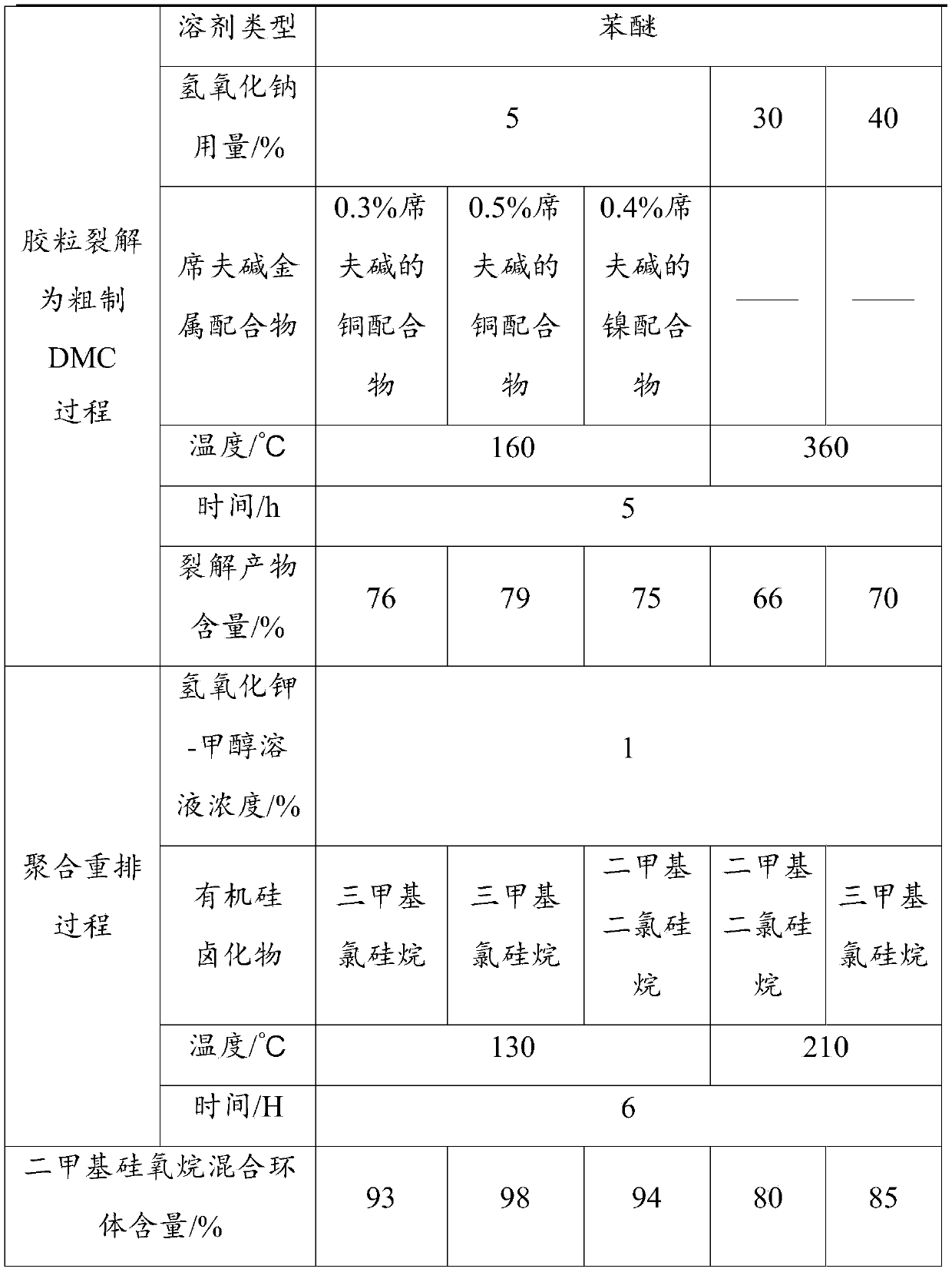

Shape correcting device for titanium alloy hemispherical shell and shape correcting method of shape correcting device

ActiveCN112246915AReduce rework costsSimple structureMetal-working feeding devicesPositioning devicesThermal deformationTitanium alloy

The invention relates to a shape correcting device for a titanium alloy hemispherical shell. The shape correcting device comprises a mold core tool, an external shape restraining tool and a locking assembly; a tool base of the mold core tool is provided with a step surface capable of being embedded into the internal molded surface of the titanium alloy hemispherical shell to be corrected, and a plurality of first through holes are formed in the step surface along the circumferential direction of the step surface; the external shape restraining tool comprises a plurality of arc-shaped tool parts, each tool part comprises a tool external shape restraining face matched with the step face to press the internal molded surface, a plurality of second through holes are formed in each tool part inthe circumferential direction of the tool part, locking through holes are formed in the two ends of each tool part, and the locking assembly comprises first locking bolts and second locking bolts, wherein the first locking bolts are connected with the first through holes and the second through holes, and the second locking bolts are used for connecting the locking through holes in every two adjacent tool parts; and the internal molded surface is pressed in the mold core tool and the external shape restraining tool through the locking assembly, the external shape restraining tool always generates radial acting force on the internal molded surface in the thermal deformation process, and therefore the purpose of shape correction is achieved.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

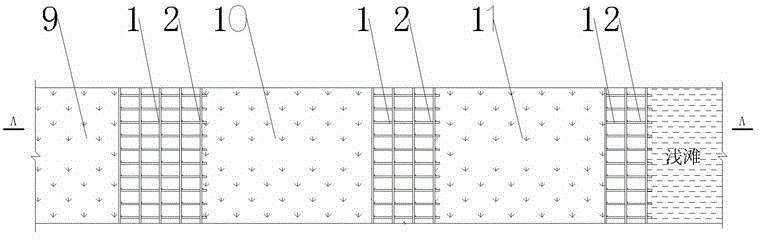

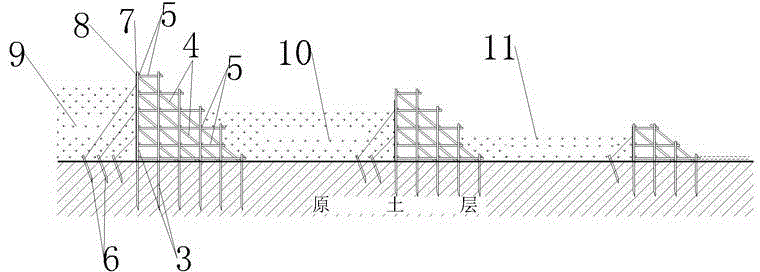

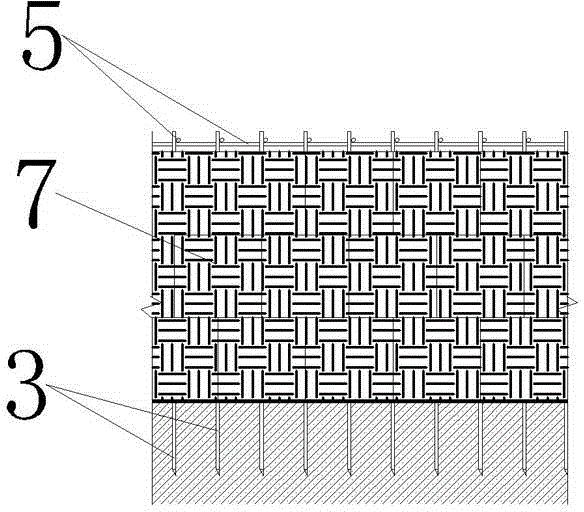

Bamboo raft pile oversized cofferdam and construction method for sea reclamation by adopting same

ActiveCN104594368AEasy constructionShort construction periodFoundation engineeringLand reclamationEngineering

The invention discloses a bamboo raft pile oversized cofferdam. The bamboo raft pile oversized cofferdam comprises at least three layers of bamboo fence retaining walls of which the heights are gradually reduced from inside to outside; each bamboo fence retaining wall comprises a moso bamboo frame erected by moso bamboo poles; a blow-filling region is formed in the inner layer of the bamboo fence retaining walls in a surrounding way; a first suppression region is formed between the second layer of the bamboo fence retaining walls and the inner layer of the bamboo fence retaining walls; a second suppression region is formed between the second layer of the bamboo fence retaining walls and the third layer of the bamboo fence retaining walls; each of the first suppression region and the second suppression region is filled with a sludge suppression layer; the height of the top surface of sludge of the blow-filling region is greater than that of the top surface of sludge of the first suppression region; the height of the top surface of the sludge of the first suppression region is greater than that of the top surface of sludge of the second suppression region. The bamboo raft pile oversized cofferdam has the following advantages that the construction is simple and convenient, and the construction duration is short; the construction cost is low; the environment-friendly degree of construction is high, and the environment cost investment is favorably reduced. The invention also provides a construction method for sea reclamation by adopting the bamboo raft pile oversized cofferdam.

Owner:泰昌建设有限公司

L-shaped profile punching device

InactiveCN111360137ARealize pressing positioningRealize automatic punchingMetal-working feeding devicesPositioning devicesPunchingGear wheel

The invention discloses an L-shaped profile punching device. The device comprises a punching table and a moving plate and is characterized in that a vertical rod is erected on the punching table, racks are arranged on the left and right sides of the vertical rod correspondingly, a left gear and a right gear are rotationally arranged in the moving plate, a left punching rod and a right punching rodare arranged in the moving plate in a sliding mode, an oblique block is arranged at the lower end of the left punching rod, an oblique sliding block is arranged in the punching table obliquely, a sliding block portion is formed at the lower end of the oblique sliding block, a rack portion is arranged at the upper end of the oblique sliding block, and a meshing gear, an intermediate gear and a rotating wheel are arranged in the punching table rotationally; and an arc toothed belt is formed on the side wall of the rotating wheel, and a second puncher pin used for punching one side of an L-shaped profile is arranged at the outer edge of the rotating wheel. According to the L-shaped profile punching device provided by the invention, the machining efficiency for L-shaped profile punching is improved, and the machining risk is reduced.

Owner:郑冬青

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com