Self-powered continuous nitration method and device

An automatic and continuous technology, applied in chemical instruments and methods, preparation of nitro compounds, preparation of organic compounds, etc., can solve the problems of large accumulation of materials and heat, high risk of reaction process, and high risk of thermal runaway. Increased heat exchange area, reduced risk of thermal runaway, effect of short residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

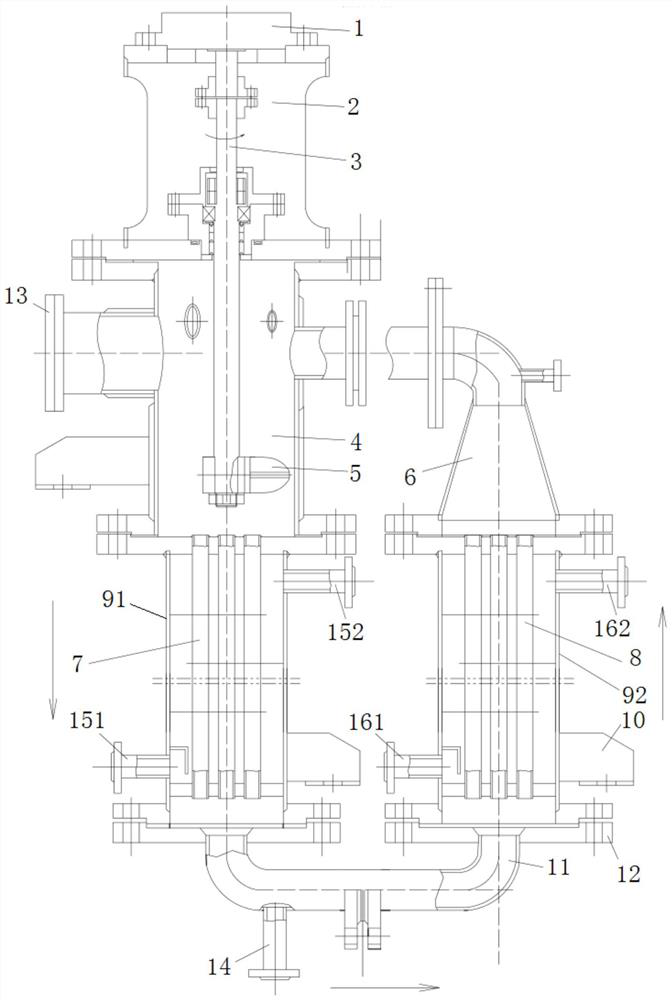

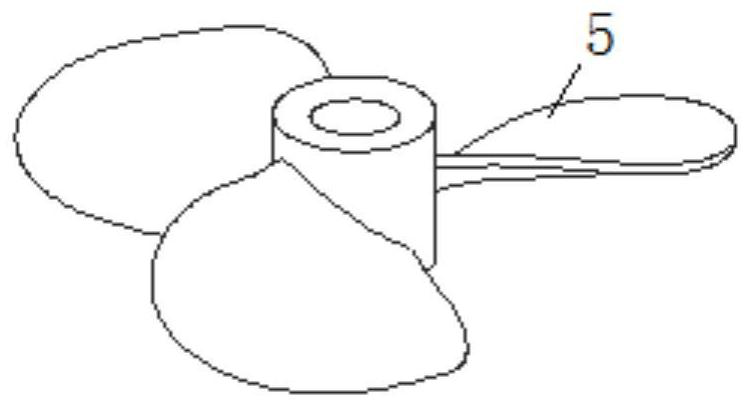

[0031] Such as figure 1 As shown, the device of the present invention includes an automatic power generation chamber 4 and two sections of circulation chambers, wherein the automatic power generation chamber 4 is provided with a rotating shaft 3 rotating in the horizontal direction and an impeller 5 integrated with the rotating shaft, and the design of the impeller angle should meet Circulation technical parameter requirements. The lower end of the automatic power generation chamber 4 is fixedly connected to the upper end of the first-stage circulation chamber, and the lower end of the first-stage circulation chamber is slowed down by the amplifying connecting pipe 11 and then connected to the lower end of the second-stage circulation chamber, and the upper end of the second-stage circulation chamber is connected to the automatic The force generating chambers 4 are connected so as to form a complete circulation. The first-stage circulation chamber is filled with heat exchange...

Embodiment 2

[0040] Utilize the device described in Example 1 to prepare 4-chloro-3,5-dinitrobenzotrifluoride using 4-chloro-3-nitrobenzotrifluoride

[0041]

[0042] In this example, 4-chloro-3-nitrobenzotrifluorotoluene, fuming nitric acid (content 98%) and fuming sulfuric acid (content 106.8%) are used as raw materials to generate 4-chloro-3-nitro Trifluorotoluene is an example, fuming nitric acid and fuming sulfuric acid are formulated into mixed acid according to the mass ratio of 1:4.45, and then the waste acid after nitrification is added through the feed port of the device to make a base, accounting for about 85% of the total volume- 90%, turn on the explosion-proof motor 1 and heat up to 118°C after the circulation of the motor is stable, mix 4-chloro-3-nitrobenzotrifluorotoluene and mixed acid at a mass ratio of 1:3.93, and then continuously add it to the reactor from the feed port after mixing. Adjust the heat exchange medium to control the temperature in the reactor to 120° ...

Embodiment 3

[0044] Preparation of 4-chloro-3,5-dinitrobenzotrifluoride from 4-chloro-3-nitrobenzotrifluoride

[0045]

[0046] In this example, 4-chloro-3-nitrotrifluorotoluene, fuming nitric acid (content 98%) and fuming sulfuric acid (content 104.5%) were used as raw materials to generate 4-chloro-3-nitrotrifluorotoluene through automatic nitration. Fluorotoluene as an example, mix fuming nitric acid and fuming sulfuric acid at a mass ratio of 1:6.67, control the temperature at 125°C, and simultaneously mix 4-chloro-3-nitrobenzotrifluoride and mixed acid at a mass ratio of 1:6.93 Feed from the kinetic reactor with a residence time of 2.5 hours. After the reaction, the material enters the layered kettle, cools down to 100°C, and stands still for 30 minutes. The organic phase is washed with aqueous sodium carbonate solution to pH = 8-9, and the product 4-chloro-3,5-dinitrobenzotrifluoride is obtained. , the content is 96.5%, and the yield is 94.2%. Using an automatic power reactor, o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com