Miniature throttling refrigerating machine based on micro-electro-mechanical system heating technology

A technology of throttling refrigerators and micro-electromechanical systems, which is applied in the direction of refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems that impurity water molecules cannot be prevented from directly sublimating and depositing, so as to reduce irreversible heat transfer losses and reduce processing Difficulty, the effect of shortening the cooling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail in conjunction with the accompanying drawings, but this embodiment does not limit the present invention, and all similar structures and similar changes of the present invention should be included in the protection scope of the present invention.

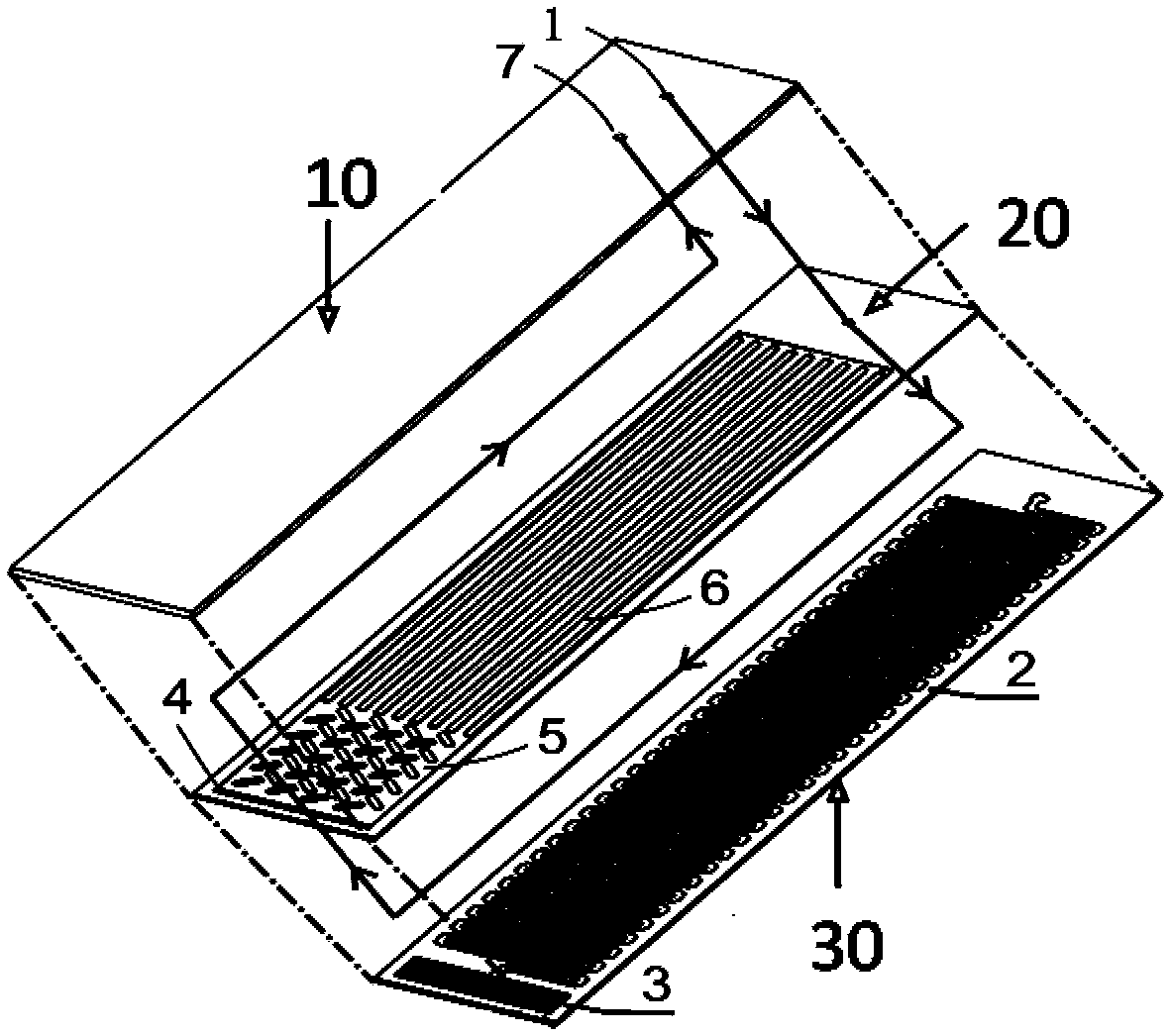

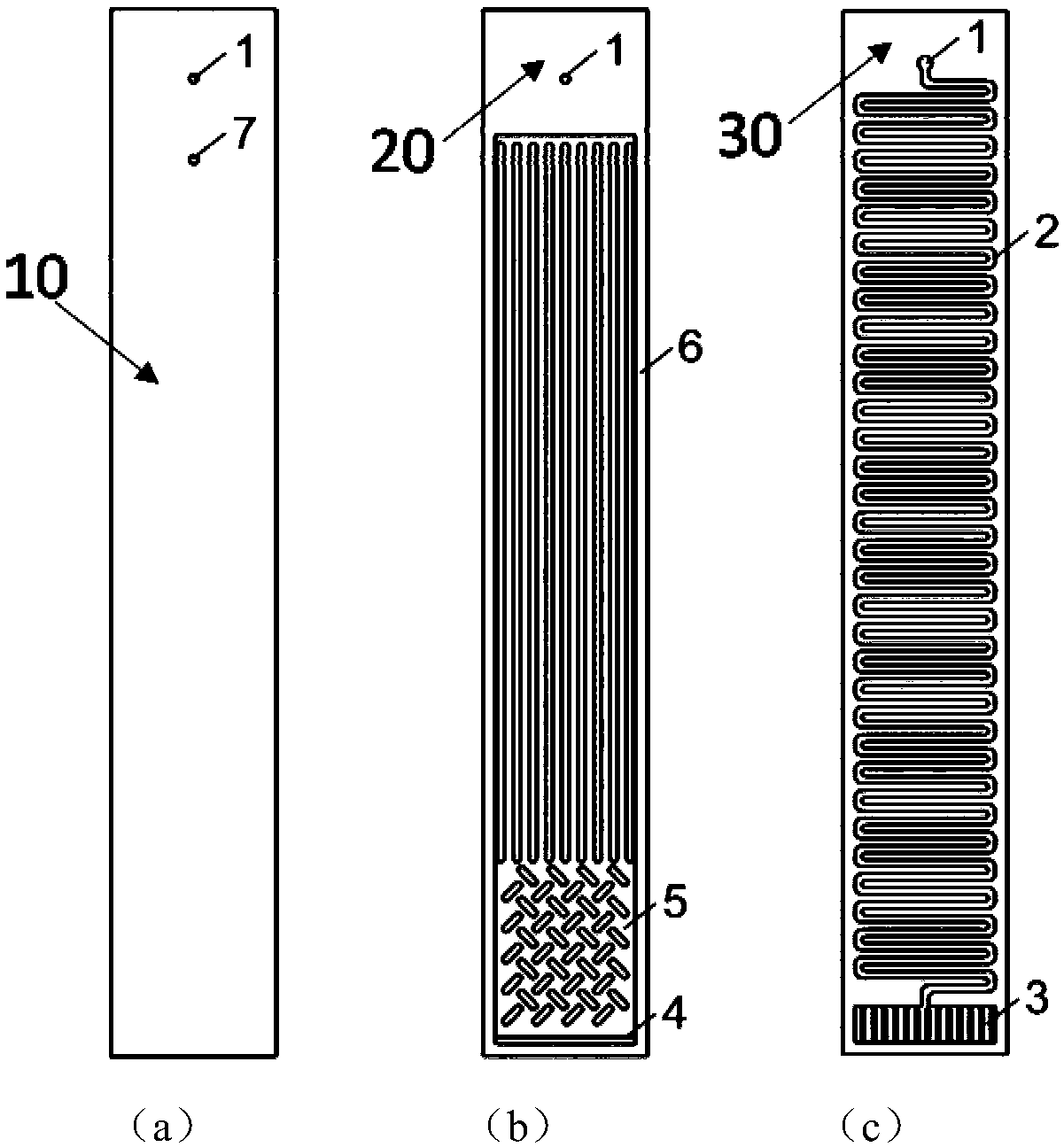

[0023] figure 1 It is an exploded view of the structure of the miniature throttling refrigerator based on the micro-electromechanical system processing technology of the present invention. The refrigerator is welded into an integrated structure by successively stacking upper, middle and lower substrates (10, 20, 30). and the lower substrates (20, 30) jointly form a microchannel heat exchanger. see figure 2, (a), (b), and (c) are the schematic structural diagrams of each layer of substrates (10, 20, 30) respectively, and the corresponding positions at one end of each layer of substrates (10, 20, 30) are provided as working The through hole of the medium inlet 1 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com