Array substrate and preparation method thereof and display panel

An array substrate and substrate layer technology, which is applied to instruments, semiconductor devices, electrical components, etc., can solve the problems of incompatibility between design and manufacturing process, damage to the electrical properties of the IGZO layer, and different etching of deep and shallow holes, so as to save manufacturing costs and save The overall process steps, the effect of optimizing the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

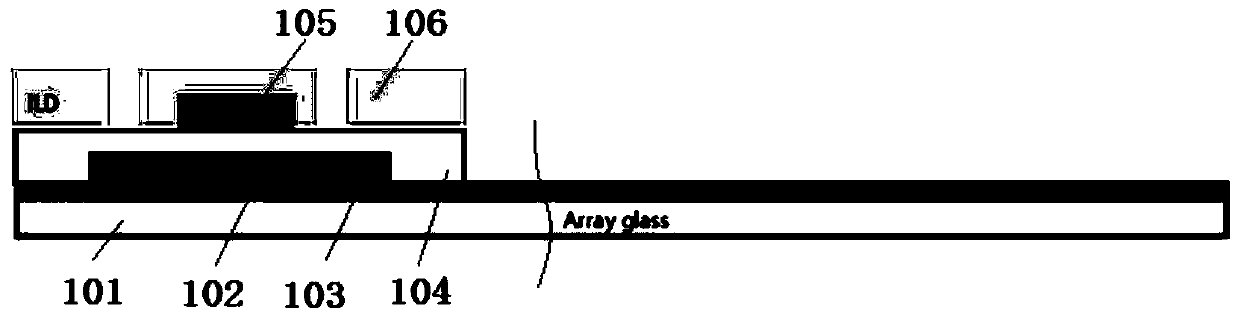

[0044] A TFT array substrate, a manufacturing method thereof and a technical solution of a display panel of the present invention will be further described in detail with reference to the accompanying drawings and embodiments.

[0045] Wherein, since the present invention also relates to a TFT array substrate and its preparation method, in order to avoid unnecessary repetition, the structure of the TFT array substrate involved in the present invention will be described below in conjunction with the preparation method of the TFT array substrate involved in the present invention. Illustrate by example.

[0046] One embodiment of the present invention provides a method for preparing a TFT array substrate, which includes the following steps:

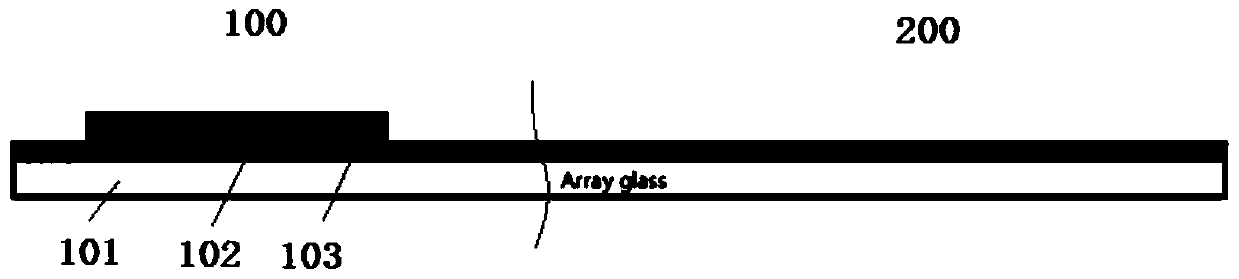

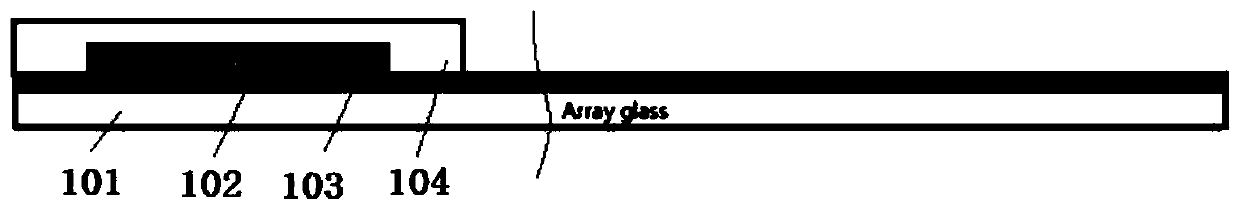

[0047] Step S1 , providing a substrate layer, which defines a first region 100 and a second region 200 , and the first TFT is fabricated in the first region of the substrate layer. Wherein the first area 100 is preferably a GOA area, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com