A preparation of tial 3 Alloy and purify the method that contains Fe waste aluminum alloy

A technology for scrap aluminum alloy and aluminum alloy, which is applied in the direction of improving process efficiency to achieve the effects of sufficient heat and mass transfer, environmentally friendly recycling, and enhanced impurity removal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

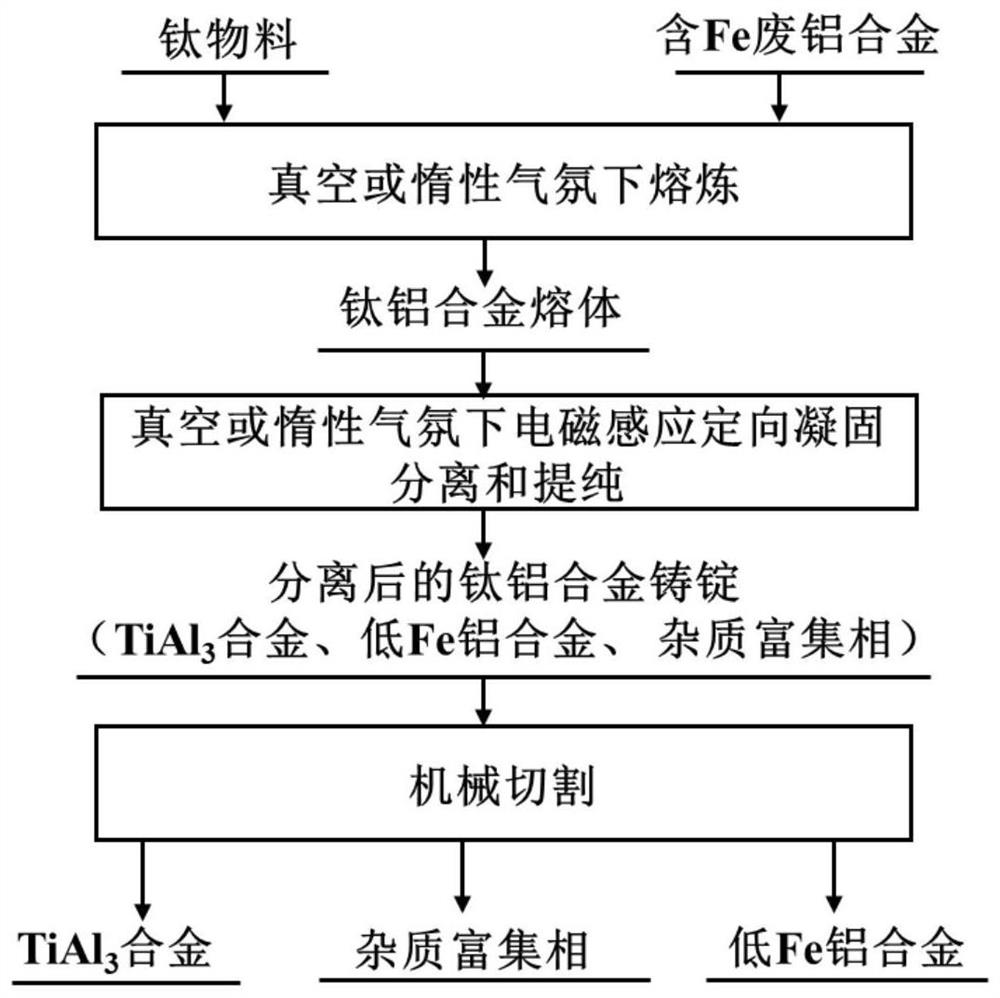

[0021] Example 1: A kind of preparation of TiAl 3 And the method for purifying Fe-containing scrap aluminum alloy (see figure 1 ), the specific steps include:

[0022] (1) The Fe-containing scrap aluminum alloy with a purity of 92.97% (main impurities and their contents are: 1.01% Fe, 2.41% Si, 0.89% Mg, 1.25% Zn, 0.52% Mn and 0.95% Cu) and a purity of 99.6% % sponge titanium (the main impurities and their contents are: 0.08% Fe, 0.02% Si and 0.01% Mg) are mixed uniformly to obtain a mixture, and then placed in a directional solidification furnace of electromagnetic induction heating under the condition of vacuum degree of 6Pa (frequency 30KHZ) ), electromagnetic induction heating the mixture to melting (1400) ℃ and smelting for 1h to fully volatilize the volatile impurities Mg and Zn to obtain a titanium-aluminum alloy melt with uniform composition; the mass ratio of Fe-containing scrap aluminum alloy to sponge titanium is 4 : 1; the removal rates of Mg and Zn were 51.9% an...

Embodiment 2

[0026] Example 2: A kind of preparation of TiAl 3 And the method for purifying Fe-containing scrap aluminum alloy (see figure 1 ), the specific steps include:

[0027] (1) The Fe-containing scrap aluminum alloy with a purity of 92.97% (main impurities and their contents are: 1.01% Fe, 2.41% Si, 0.89% Mg, 1.25% Zn, 0.52% Mn and 0.95% Cu) and a purity of 96.5% % of waste titanium-aluminum alloy (containing 93% Ti and 3.5% Al, the main impurities and their contents are: 1.8% Mn and 0.6% Fe) were mixed uniformly to obtain a mixture, and then placed in an electromagnetic induction heating furnace under the condition of vacuum degree of 1Pa. In a directional solidification furnace (frequency 45KHZ), electromagnetic induction heating the mixture to melting (1450) ℃ and smelting for 1.5h to fully volatilize the volatile impurities Mg and Zn to obtain a titanium-aluminum alloy melt with uniform composition; which contains Fe scrap aluminum alloy The mass ratio to sponge titanium is 7...

Embodiment 3

[0031] Embodiment 3: a kind of preparation TiAl 3 And the method for purifying Fe-containing scrap aluminum alloy (see figure 1 ), the specific steps include:

[0032] (1) The Fe-containing scrap aluminum alloy with a purity of 90.16% (main impurities and their contents are: 1.75% Fe, 3.18% Si, 0.58% Mg, 1.27% Zn, 1.56% Mn and 1.50% Cu) and a purity of 99.5% % sponge titanium (main impurities and their contents: 0.12% Fe, 0.03% Si, 0.04% Mg) are mixed uniformly to obtain a mixture, and then placed in an electromagnetic induction heating directional solidification furnace under an inert atmosphere (argon) ( Frequency 60KHZ), electromagnetic induction heating the mixture to melting (1350) ℃ and smelting for 1h to fully volatilize the volatile impurities Mg and Zn to obtain a titanium-aluminum alloy melt with uniform composition; the mass ratio of Fe-containing scrap aluminum alloy to sponge titanium is 5:1; the removal rates of Mg and Zn are 49.8% and 92.1%;

[0033] (2) Unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com