Gasification oil range

An oil stove and oil pipeline technology, which is applied in the field of kitchen supplies, can solve the problems of unusable use effect of oil, low and poor fuel utilization rate, etc., and achieve the effects of sufficient gasification, energy saving, and high heat utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

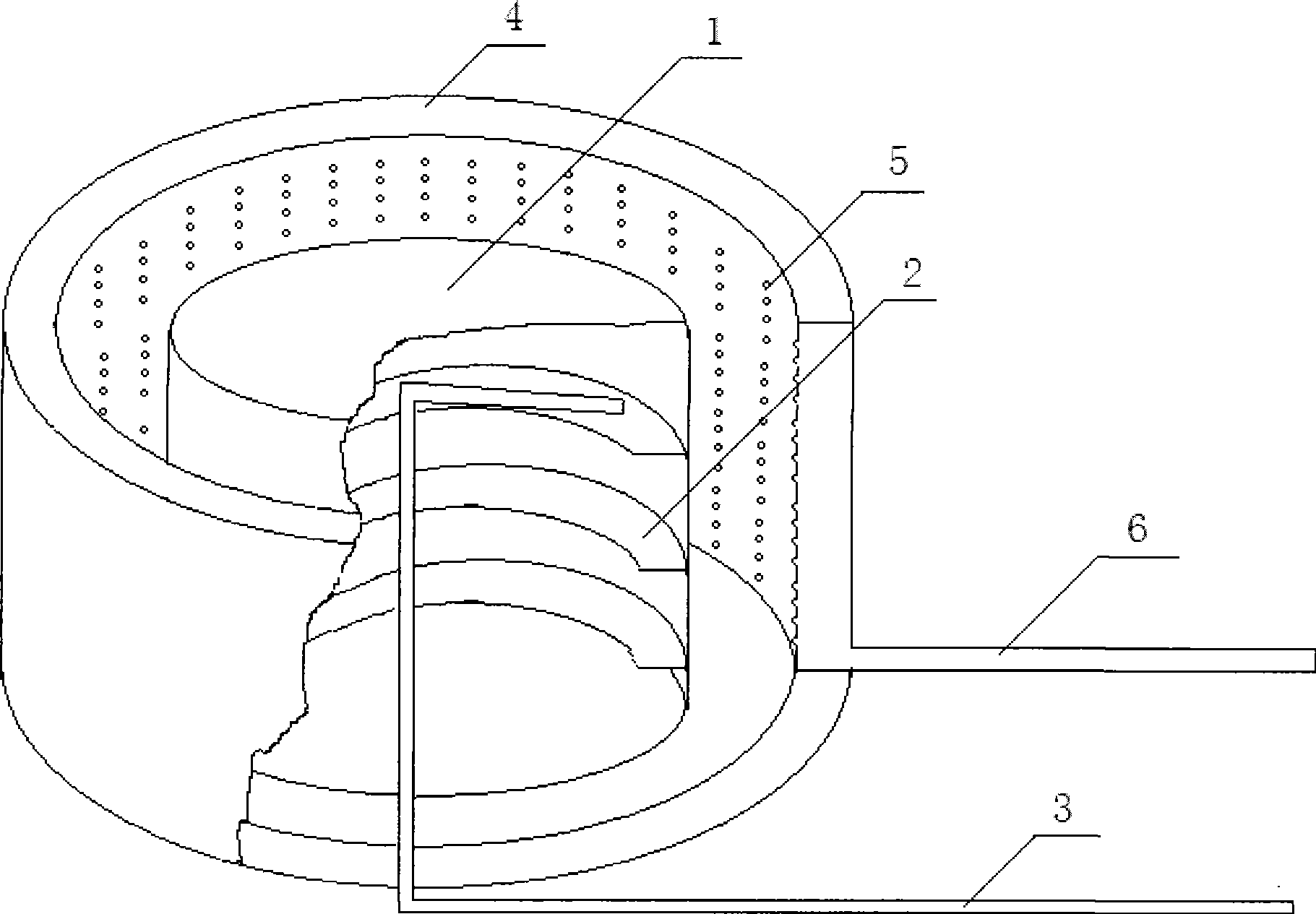

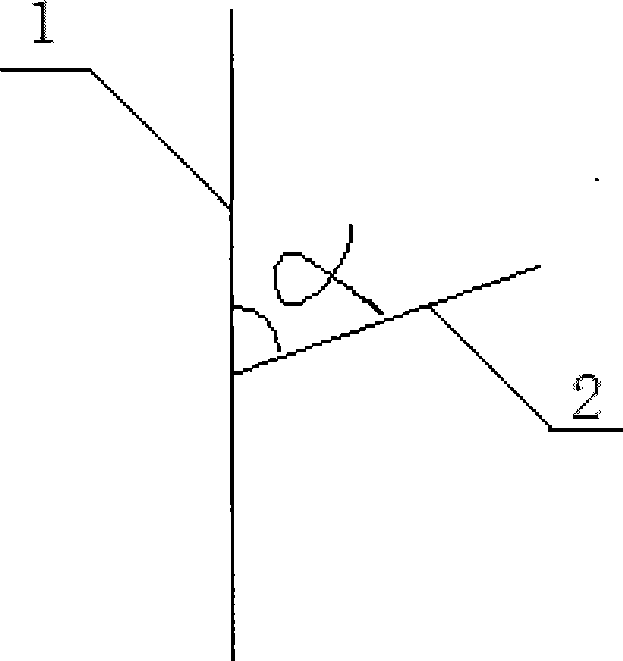

[0012] Embodiment 1 In the gasification oil stove of the present invention, the furnace 4, the gasification hood 1 and the deflector are all made of metal, and the furnace 4 is provided with a gasification hood 1, and the inner wall of the gasification hood 1 is provided with a deflector 2; The oil delivery pipe 3 is arranged in the gasification hood 1; the inner wall of the furnace 4 is provided with several air holes 5. The deflector 2 in the gasification hood 1 is an integral plate that rotates downward. The included angle between the deflector 2 in the gasification hood 1 and the inner wall of the gasification hood 1 is about 70 degrees. Gasification oil cooker first ignites fuel when in use, gasification hood 1 temperature rises very soon, after fuel gasification, escapes from gasification hood 1 bottom and contacts with the air that comes out from air hole 5 and burns.

Embodiment 2

[0013] Embodiment 2 In the gasification oil stove of the present invention, the furnace 4, the gasification hood 1 and the deflector are all made of metal, and the furnace 4 is provided with a gasification hood 1, and the inner wall of the gasification hood 1 is provided with a deflector 2; The oil delivery pipe 3 is arranged in the gasification hood 1; the inner wall of the furnace 4 is provided with several air holes 5. The deflector 2 in the gasification hood 1 is five mutually disconnected plates. The included angle between the deflector 2 in the gasification hood 1 and the inner wall of the gasification hood 1 is about 75 degrees. Gasification oil cooker first ignites fuel when in use, gasification hood 1 temperature rises very soon, after fuel gasification, escapes from gasification hood 1 bottom and contacts with the air that comes out from air hole 5 and burns.

Embodiment 3

[0014] Embodiment 3 In the gasification oil stove of the present invention, the furnace 4, the gasification hood 1 and the deflector are all made of metal, and the furnace 4 is provided with a gasification hood 1, and the inner wall of the gasification hood 1 is provided with a deflector 2; The oil delivery pipe 3 is arranged in the gasification hood 1; the inner wall of the furnace 4 is provided with several air holes 5. The deflector 2 in the gasification hood 1 is 8 mutually disconnected plates. The included angle between the deflector 2 in the gasification hood 1 and the inner wall of the gasification hood 1 is about 65 degrees. Gasification oil cooker first ignites fuel when in use, gasification hood 1 temperature rises very soon, after fuel gasification, escapes from gasification hood 1 bottom and contacts with the air that comes out from air hole 5 and burns.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com