Infrared flameless gasification stove

A gasification stove and infrared technology, applied in the field of gasification stoves, can solve the problems of incomplete combustion, low calorific value, easy blockage of preheating oil pipes, etc., and achieve the effect of protecting the environment and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

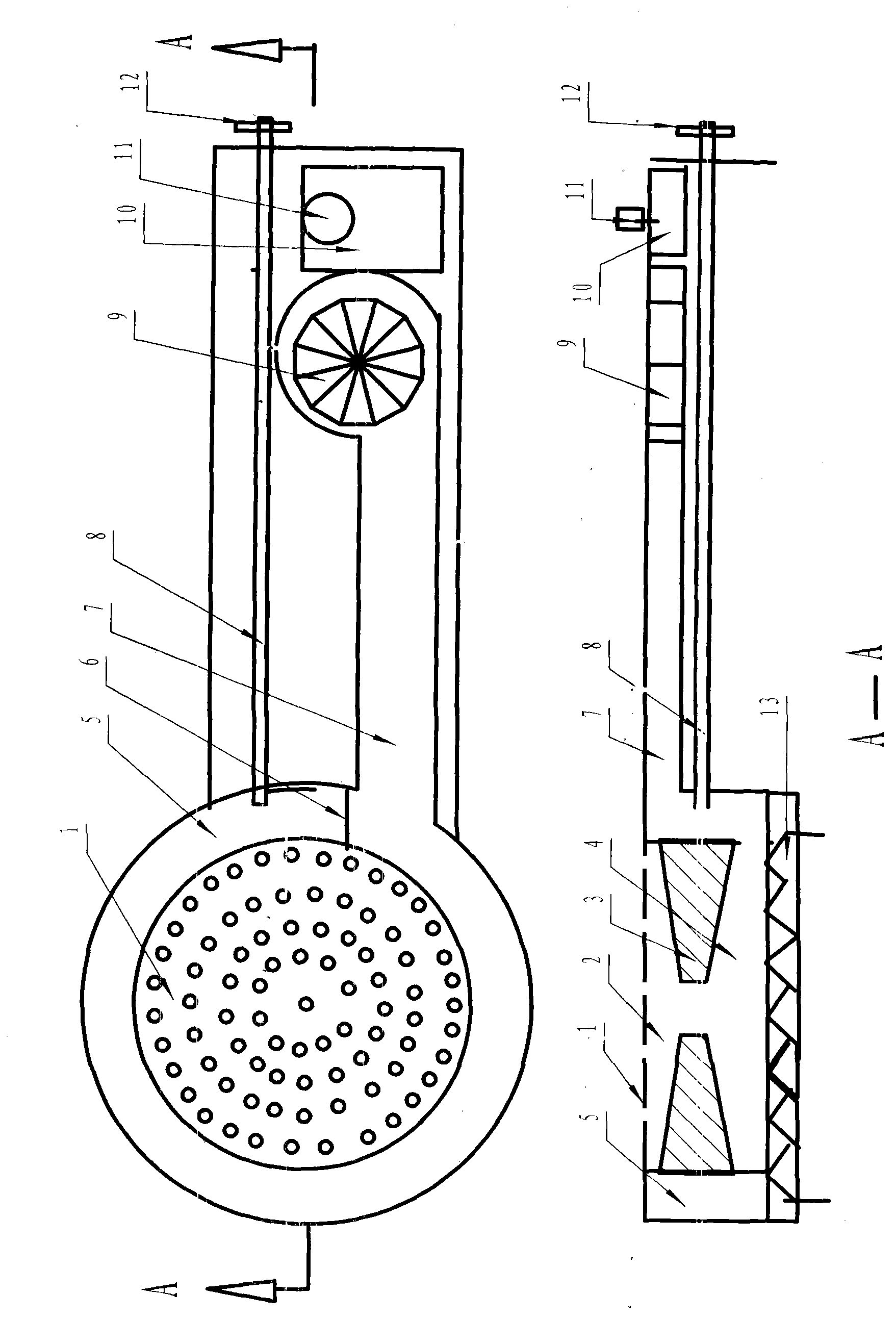

[0018] As shown in Figure 1, the ceramic infrared combustion disc 1 is a cake-shaped disc with a number of air-permeable holes evenly distributed on the plane, and the outer wall of the annular preheating air duct 5 is a barrel-shaped structure with a bottom and a flange on the mouth edge. The ceramic infrared combustion disk 1 and the ceramic fire gathering ring 3 are a cylindrical structure with no cover on the top, bottomless bottom, and a flange on the mouth. The inner diameter of the annular preheating air duct 5, when the components 1, 3, and 5 are combined according to the design, the annular preheating air duct 5, the combustion chamber 2, and the fuel gasification chamber 4 are formed between them. The windshield 6 is vertical Placed in the ring-shaped preheating air duct 5, so that the air must go around the ring-shaped preheating air duct 5 before entering the gasification chamber, so as to increase the temperature of the incoming air

[0019] The heating wire is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com