Sulfur-nitrogen crystalline silica cracking tube

A pyrolysis tube and quartz technology, applied in the direction of combustion method, laboratory equipment, combustion type, etc., can solve the problems of lowering the sample temperature, incomplete gasification of the sample, and affecting the accuracy of the test results, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

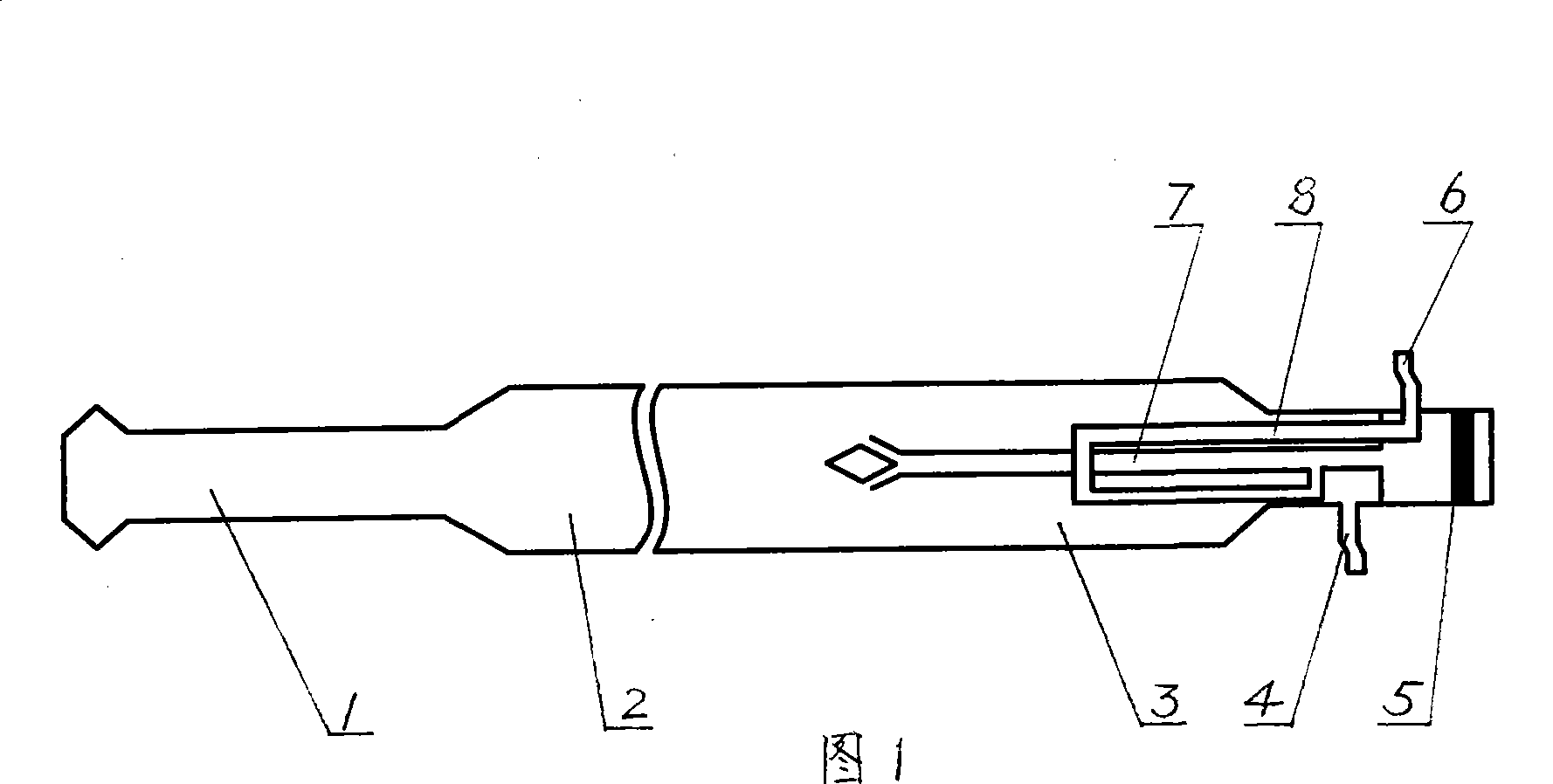

[0009] Example 1: Referring to Figure 1, the middle section of the sulfur nitrogen quartz cracking tube is the combustion chamber 2, and the two ends are the gasification end 3 and the stable end 1 respectively. There is a gasification chamber 7 inside the gasification end, and a U-shaped carrier gas preheating pipe 8 is arranged between the inner wall of the gasification end and the outer wall of the gasification chamber. One end of the preheating pipe communicates with the gasification chamber, and the other end communicates with the carrier gas port. There is a gap with the inner wall of the gasification end, and the connection between the preheating tube and the gasification chamber is 5cm away from the gasification end port.

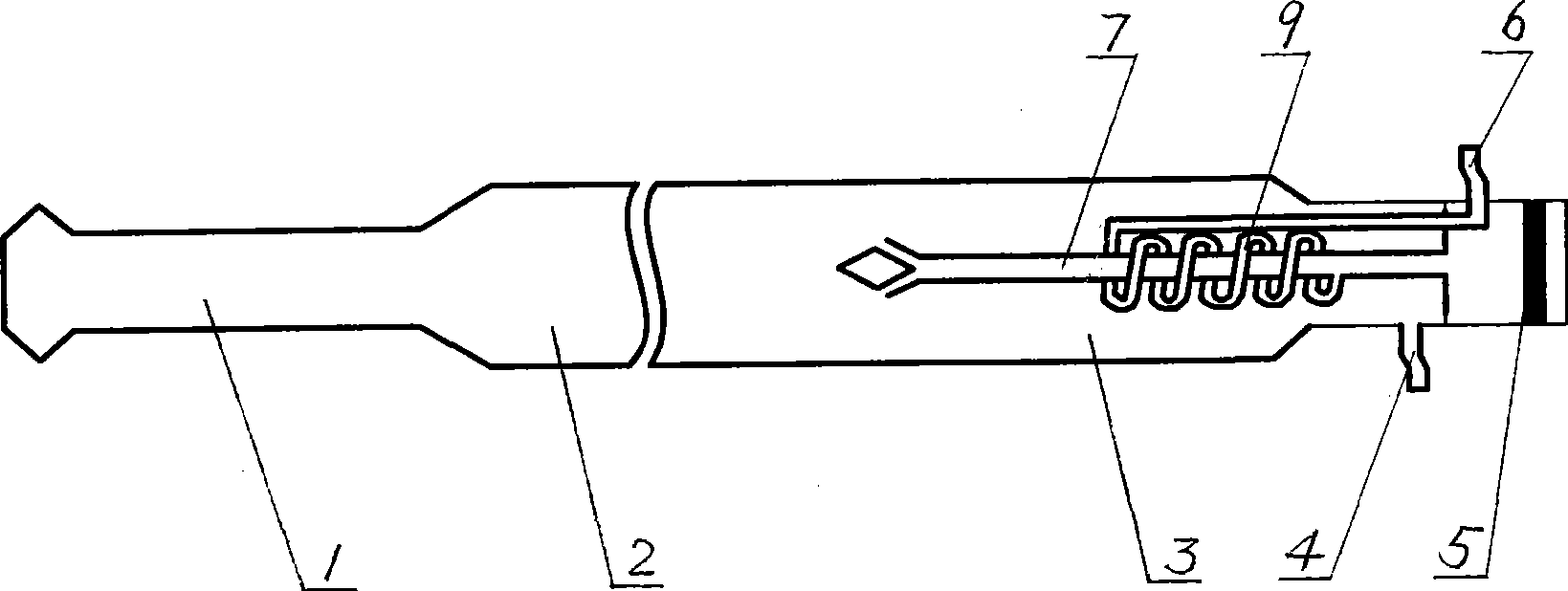

[0010] Example 2: see figure 2 , between the inner wall of the gasification end 3 and the outer wall of the gasification chamber 7, there is a spiral carrier gas preheating tube 9 surrounding the gasification chamber. Same example one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com