Motor vehicle heating system

A heater, automotive technology, used in lighting and heating equipment, heating/cooling equipment, vehicle components, etc., to solve problems such as unstable burners, no support, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

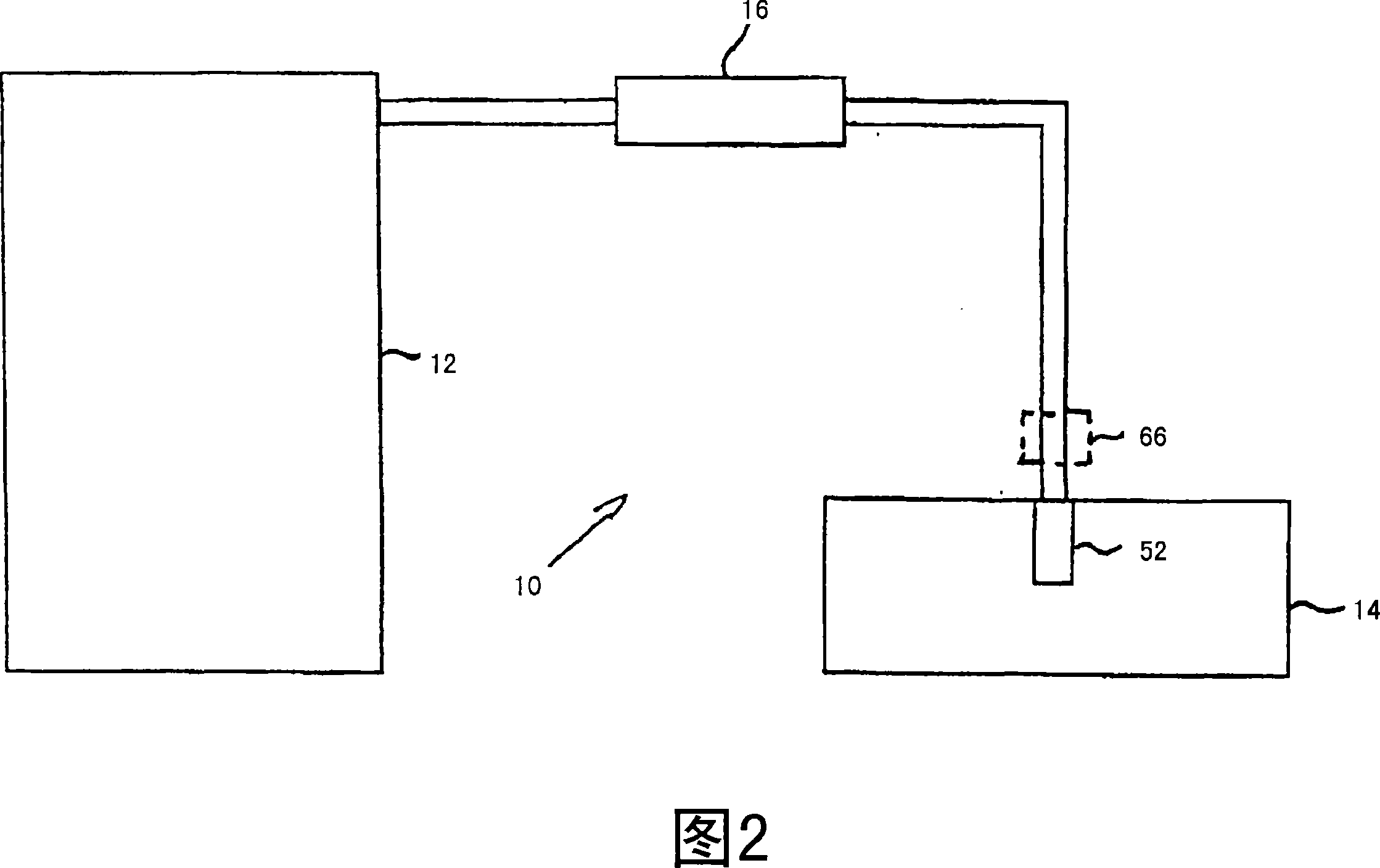

[0025] FIG. 2 shows a schematic block diagram illustrating an embodiment of the vehicle heater of the present invention. The vehicle heater 10 shown here can be a further heater or, for example, an auxiliary heater. The vehicle heater 10 shown here includes a reciprocating piston fuel pump 16 by means of which liquid fuel can be delivered from a fuel tank 12 to a burner / heat exchanger unit 14 . Depending on whether air heating or water heating is used, the burner / heat exchanger unit is connected to other air and / or water lines (not shown here), which are well known to those skilled in the art. The burner / heat exchanger unit 14 also comprises a fuel valve 52, by means of which the fuel supply can be partially or completely cut off. This fuel valve 52 does not have to be integrated in the fuel / heat exchanger unit 14 , but can actually also be arranged between the reciprocating piston fuel pump 16 and the burner / heat exchanger unit 14 .

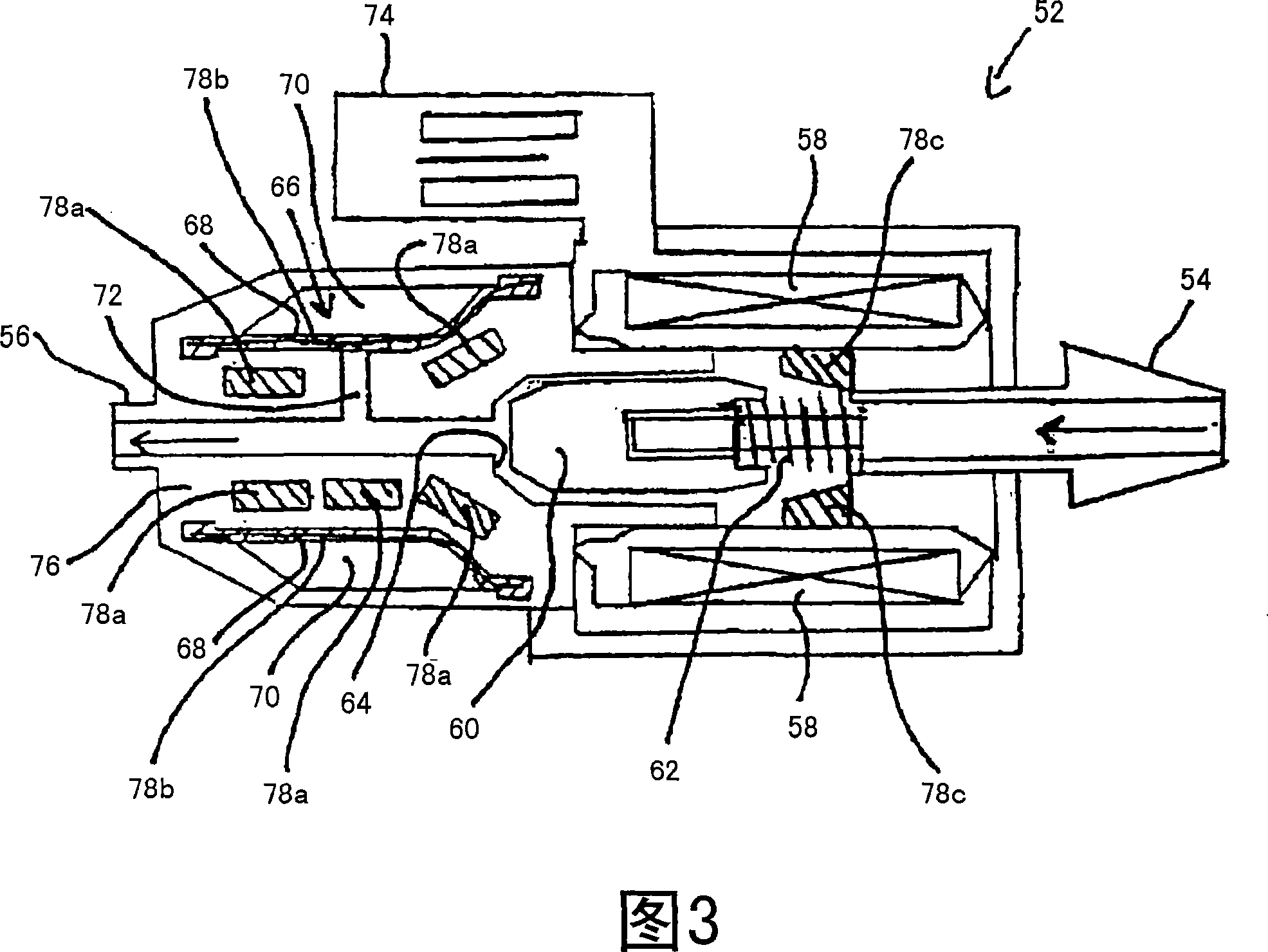

[0026] The damping element 66 and the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com