Reasonably-structured special power vaporizer for high-efficiency methanol burner

A vaporizer and burner technology, which is applied in the field of high-efficiency methanol burner special power vaporizers, can solve problems such as a large amount of exhaust gas and pollute the environment, and achieve the effects of low production cost, long service life and easy realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

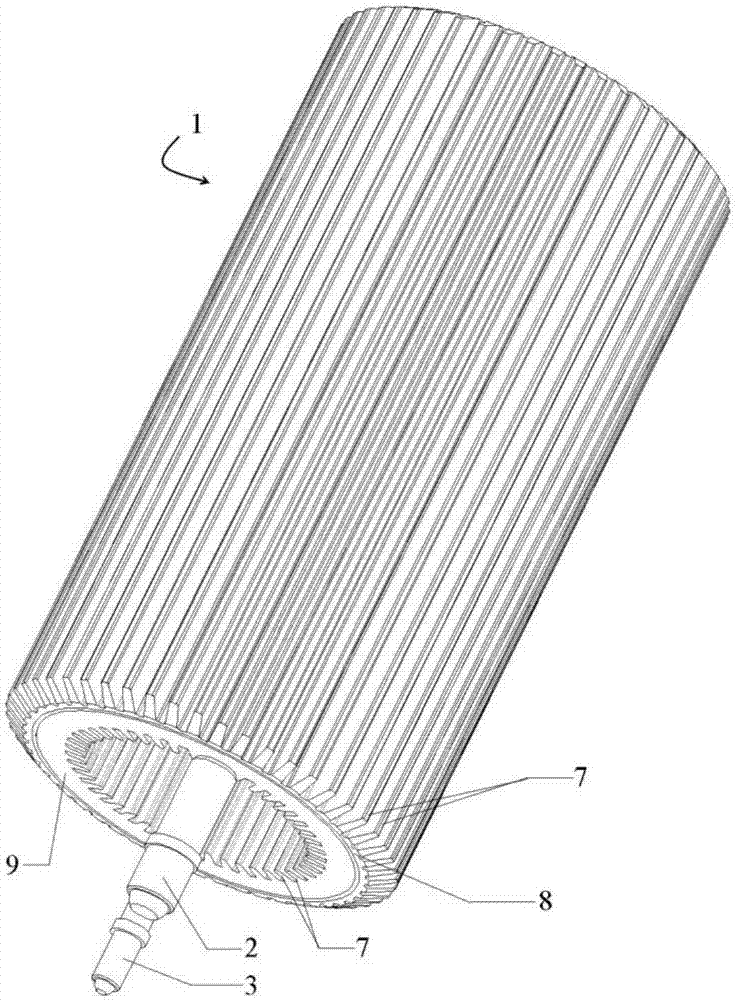

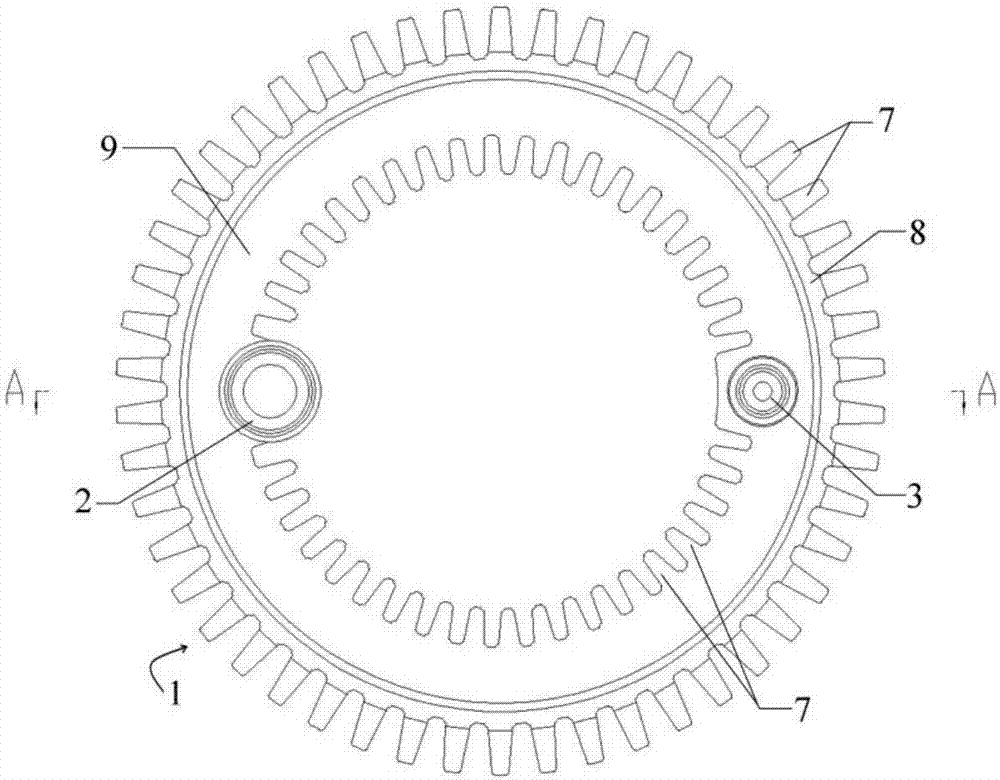

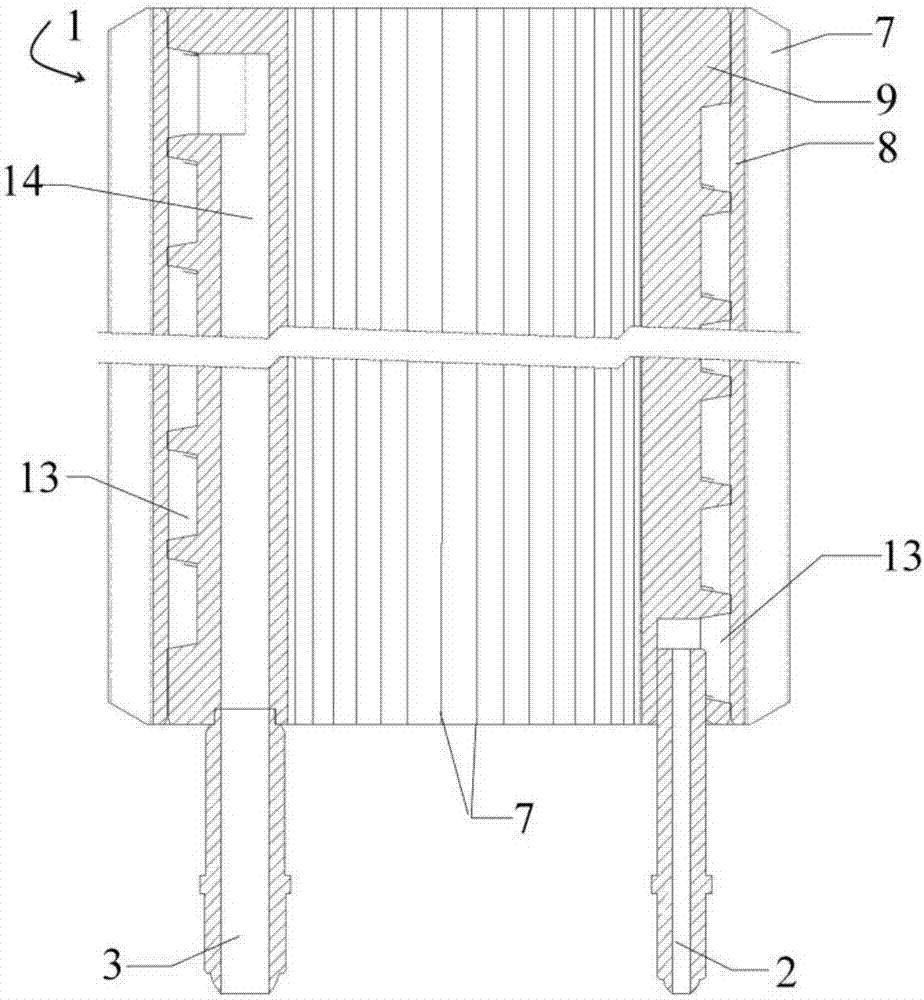

[0032] Such as Figure 1-2 The shown power carburetor with reasonable structure and dedicated to high-efficiency methanol burners includes a power carburetor body 1, and the bottom of the power carburetor body 1 is respectively provided with a methanol liquid inlet 2 and a methanol vaporization outlet 3. The power carburetor body 1 includes a carburetor outer casing 8 and a carburetor inner casing 9 , wherein the power carburetor body 1 is a hollow cylindrical power carburetor body 1 . In addition, a group of ribs 7 are uniformly provided on the carburetor outer casing 8 and the carburetor inner casing 9 . Moreover, the fins 7 are arranged on the carburetor outer casing 8 and the carburetor inner casing 9 from top to bottom. The carburetor body 1 , methanol liquid inlet 2 , methanol vaporization outlet 3 and fins 7 are made of stainless steel, and a high-temperature-resistant coated sand layer is provided on the outside of the stainless steel material.

[0033] In addition, ...

Embodiment 2

[0035] Such as Figure 1-2The shown power carburetor with reasonable structure and dedicated to high-efficiency methanol burners includes a power carburetor body 1, and the bottom of the power carburetor body 1 is respectively provided with a methanol liquid inlet 2 and a methanol vaporization outlet 3. The power carburetor body 1 includes a carburetor outer casing 8 and a carburetor inner casing 9 , wherein the power carburetor body 1 is a hollow cylindrical power carburetor body 1 . In addition, a group of ribs 7 are uniformly provided on the carburetor outer casing 8 and the carburetor inner casing 9 . Moreover, the fins 7 are arranged on the carburetor outer casing 8 and the carburetor inner casing 9 from top to bottom. The carburetor body 1 , methanol liquid inlet 2 , methanol vaporization outlet 3 and fins 7 are made of stainless steel, and a high-temperature-resistant coated sand layer is provided on the outside of the stainless steel material.

[0036] In addition, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com