Method for eliminating carbon deposition in roller-bottom continuous nodulizing annealing furnace

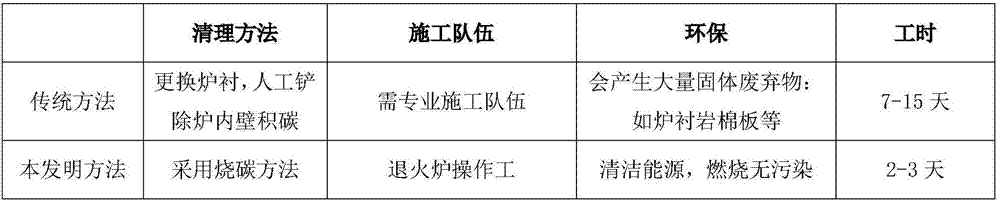

A technology of spheroidizing annealing furnace and annealing furnace, which is applied in furnaces, heat treatment furnaces, furnace types, etc., can solve the problems of solid waste environmental pollution, carbonization of annealing materials, and high degree of specialization, and achieves a short cleaning operation period and a high level of operation. Process stability and pollution reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Remove the carbon deposits in the roller-hearth continuous spheroidizing annealing furnace as follows:

[0020] a. Keep the roller hearth continuous spheroidizing annealing furnace in an empty state, close the RX gas inlet valve of the annealing furnace, and close the furnace doors on both sides of the annealing furnace; RX gas is a protective gas to prevent the furnace body steel of the annealing furnace under high temperature The structure, furnace bottom roller and annealing material are oxidized to provide protective gas, the main components are carbon monoxide and carbon dioxide;

[0021] b. Heat the annealing furnace by burning natural gas in the radiant tube to produce high-temperature radiation, control the temperature in the furnace to 650℃ and keep it at a constant temperature for 4-5 hours, and detect the exhaust gas of the annealing furnace and CO in the exhaust gas 2 The content value continues to rise, when CO 2 The content value reaches a constant value and doe...

Embodiment 2

[0025] Remove the carbon deposits in the roller-hearth continuous spheroidizing annealing furnace as follows:

[0026] a. Keep the roller-hearth continuous spheroidizing annealing furnace empty, close the RX gas inlet valve of the annealing furnace, and close the furnace doors on both sides of the annealing furnace;

[0027] b. Heat the annealing furnace by burning natural gas in the radiant tube to produce high-temperature radiation, control the temperature in the furnace to 650±10℃ and keep it at a constant temperature for 4-5 hours, and detect the exhaust gas of the annealing furnace and CO in the exhaust gas 2 The content value continues to rise, when CO 2 The content value reaches a constant value and does not change (keep it unchanged for 30 minutes), stop heating at this time, and open the furnace doors on both sides;

[0028] c. After the air enters the annealing furnace and fills the furnace (no need to control the temperature, 30 minutes after opening the furnace door), clos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com