New energy turbine engine

A turbine engine and engine technology, which is applied to machines/engines, gas turbine devices, mechanical equipment, etc., can solve the problems of low fuel utilization rate, low energy utilization efficiency, incomplete combustion, etc., so as to reduce the content of harmful toxic gases and alleviate Energy stress, the effect of removing glue carbon deposits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] specific implementation plan

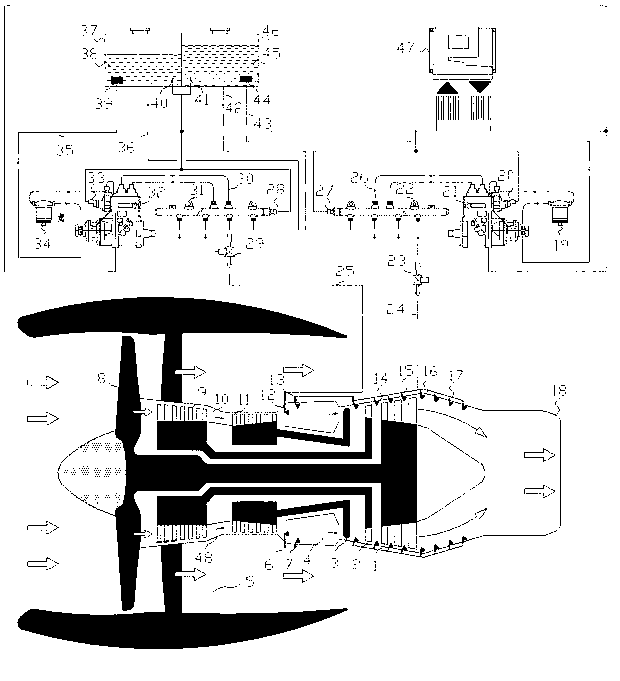

[0013] Refer to attached figure 1 :

[0014]Fuel injection system: computer ECU (47), fuel tank (37), fuel (38), fuel primary filter (39), fuel level sensor (40), fuel fine filter (34), annular fuel pipe (6), High-pressure fuel pump pressure sensor (33), fuel return pipe (36), low-pressure fuel pipe (35), high-pressure fuel pump (32), fuel common rail pipe sensor (28), fuel injection control valve (29), input high-pressure fuel pipe (30), annular fuel pipe (6), fuel injector (12).

[0015] Water injection system: computer ECU (47), water tank (46), water (45), water primary filter (44), water level sensor (41), water fine filter (19), high pressure water pump pressure sensor (20), high pressure water pump (21), high pressure water common rail pipe (22), input high pressure water pipe (26), high pressure common rail water pressure sensor (27), water injection control valve (23), output high pressure water pipe (24), water return pipe (42...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com