Throttle valve structure and self-cleaning method for throttle valve carbon deposit

A throttle and self-cleaning technology, which is applied to engine components, engine control, machine/engine, etc., can solve the problems of the engine not working normally, and achieve the effect of solving the carbon deposit of the throttle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

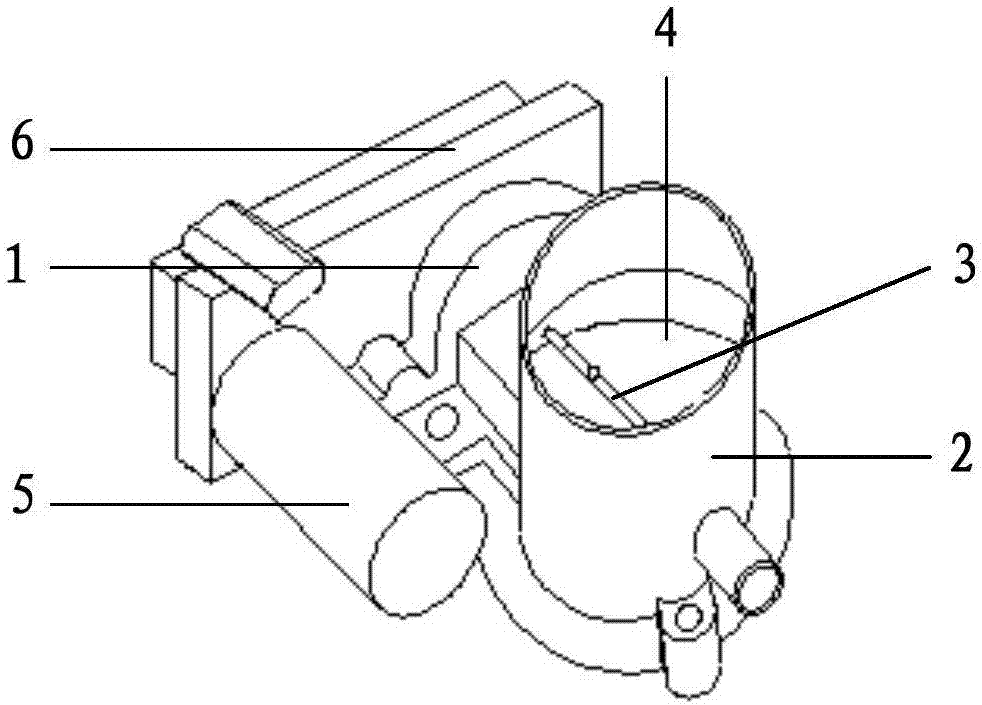

[0050] Such as figure 1 As shown, the embodiment of the present invention provides a throttle valve structure, including:

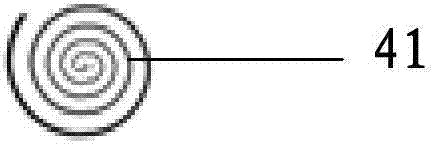

[0051] Valve body 1; intake pipe 2 installed on the valve body 1; butterfly valve shaft 3 vertically arranged inside the intake pipe 2; butterfly valve 4 installed on the butterfly valve shaft 3; integrated inside the butterfly valve 4 The heating wire 41; the power regulator connected with the heating wire 41; and the engine control unit ECU connected with the power regulator and the butterfly valve shaft 3;

[0052] Wherein, the ECU obtains the preset system value of the throttle valve by controlling the rotation of the butterfly valve shaft 3 and driving the butterfly valve 4; obtains the degree of carbon deposit in the throttle valve according to the system value; The degree of controlling the power regulator selects the heating mode of the heating wire 41, and controls the heating of the heating wire 41 according to the heating mode of the heating w...

Embodiment 2

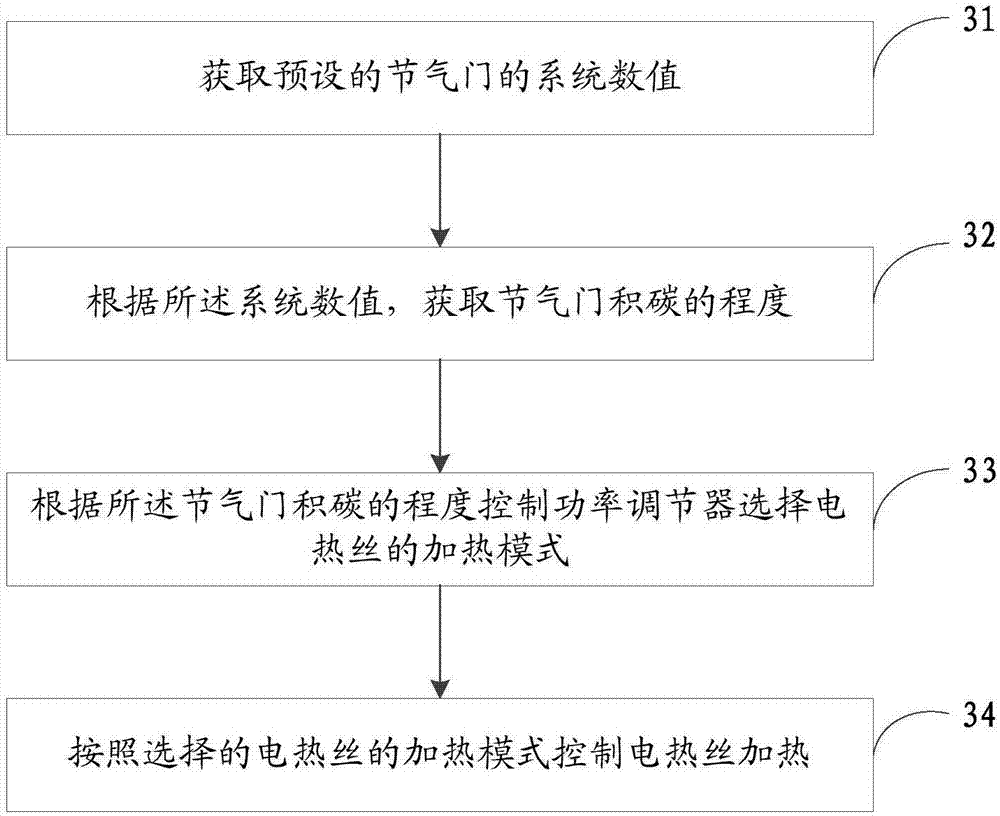

[0065] Such as image 3 Shown, the embodiment of the present invention also provides a kind of self-cleaning method of throttle valve carbon deposition, comprising:

[0066] Step 31, obtaining the preset system value of the throttle;

[0067] Step 32, according to the system value, obtain the degree of carbon deposit in the throttle valve;

[0068] Step 33. Control the power regulator to select the heating mode of the heating wire according to the degree of carbon deposit in the throttle valve;

[0069] Step 34: Control the heating of the heating wire according to the heating mode of the heating wire selected.

[0070] In this embodiment, before the ECU controls the carbon deposit self-cleaning of the throttle valve, it is necessary to first judge whether the vehicle system meets the self-cleaning condition, that is, whether there is a fault related to the throttle body in the vehicle engine control system, and if the self-cleaning condition is not satisfied, then Exit self...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com