A compression head and a compression device

A technology of a pressing device and a pressing head, which is applied to auxiliary devices, metal processing equipment, auxiliary welding equipment, etc., can solve the problems of scrapped mask 100', uneven surface, weak welding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

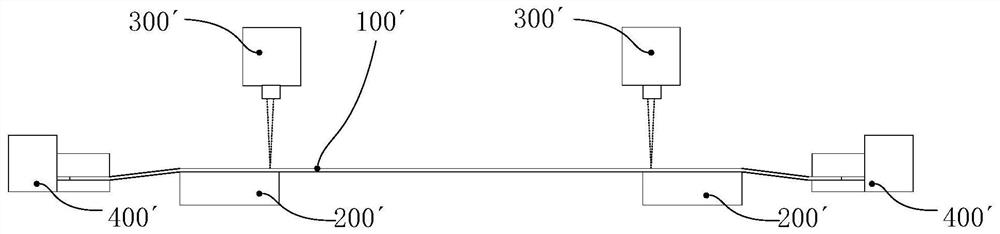

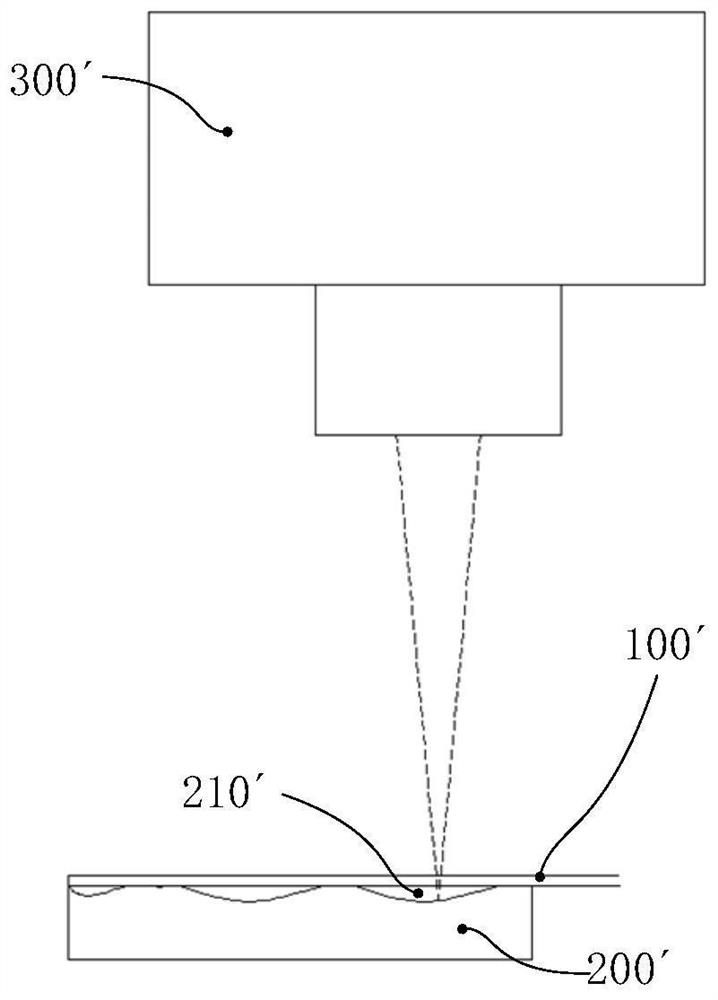

[0056] Such as Figure 4 As shown, this embodiment provides a pressing device, including a pressing head 10 and a driving mechanism 20 capable of driving the pressing head 10 to move, so that the pressing head 10 can move to the position where the object to be pressed needs to be pressed. Among them, the pressing device can be used in many welding fields, and this embodiment is used to illustrate the application of the pressing device to the welding of the mask 100 . The pressing head 10 mainly presses the mask 100 on the frame 200 connected thereto, and then uses the welding device 300 to perform welding.

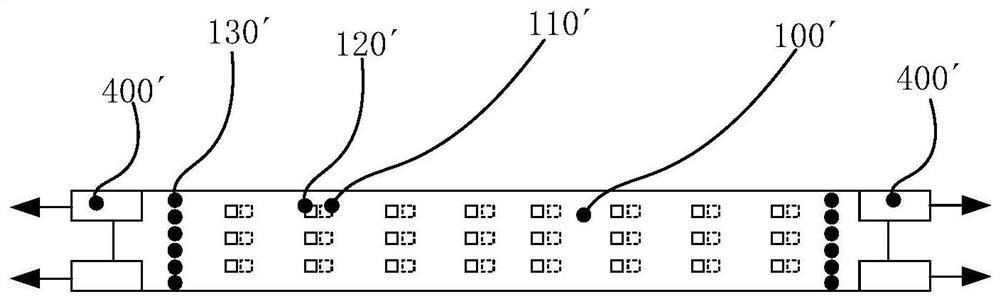

[0057] Specifically, as Figure 5 and 6 As shown, the compression head 10 includes a mounting frame 11, and the mounting frame 11 is provided with a through hole 12 for the welding beam 310 to pass through; The elastic claws can contact the mask 100 and press it elastically. After the elastic claws press the mask 100 and the frame 200 tightly, the welding beam 310 gene...

Embodiment 2

[0067] Such as Figure 10 As shown, the structure of the compression head 10 in this embodiment is basically the same as that in Embodiment 1, the difference between the two is that the elastic claws of the compression head 10 in this embodiment are made of heat-resistant rubber 15, The heat-resistant rubber 15 itself has a certain degree of compressibility, and it can be directly snapped into the installation groove of the installation frame 11 , and there is no need to reserve a space 14 between the installation frame 11 and the installation frame 11 . Wherein the heat-resistant rubber 15 can be selected from nitrile rubber, fluorine rubber and the like.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com