socket

A technology of sockets and conductive sheets, applied in the direction of fixed/insulated contact components, electrical components, coupling devices, etc., can solve the problems of time-consuming and labor-consuming welding process, low production efficiency, unsafe use, etc., and achieve a reasonable and compact space distribution. The effect of solving false welding and false welding and improving the safety of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

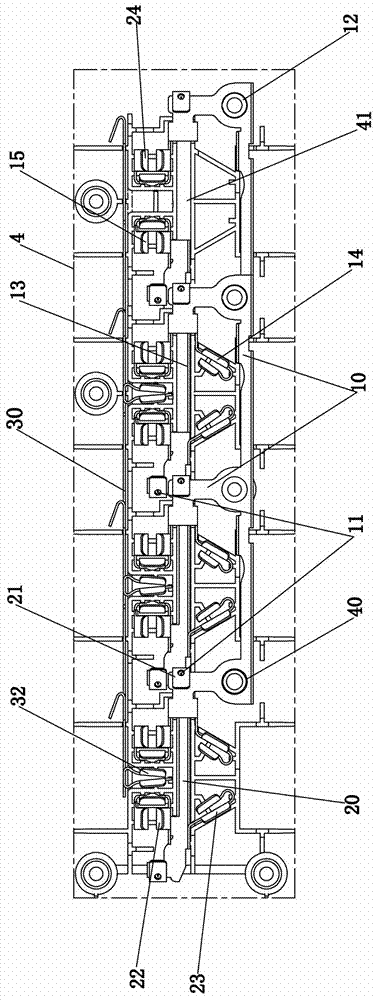

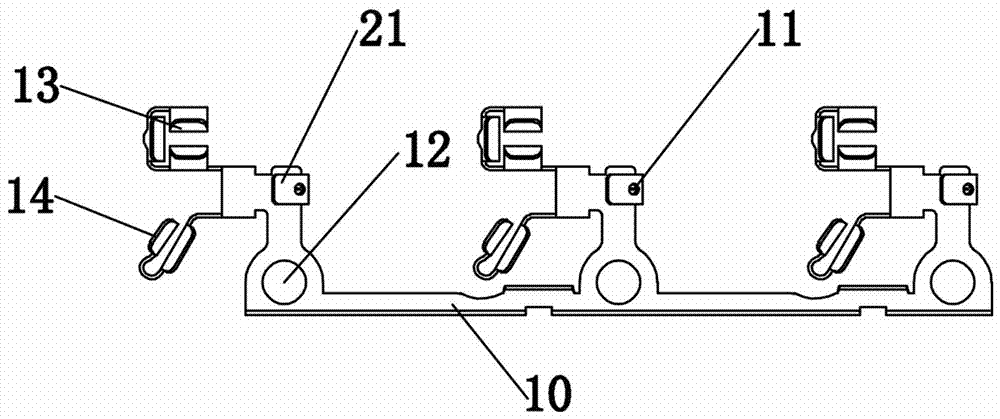

[0026] Embodiment one, such as Figure 1 to Figure 6 As shown, a socket includes a base 4, a three-phase plug (not shown in the figure), an N-pole conductive sheet 20, a two-pole N-pole socket 22, a three-pole N-pole socket 23, an independent two-pole N-pole socket Sleeve 15, L pole conductive sheet 10, two-pole L pole socket sleeve 13, three-pole L pole socket sleeve 14, independent two-pole L pole socket sleeve 24, E pole conductive sheet 30 and E pole socket sleeve 32, the base 4 The middle part is provided with a mounting groove 41 along its length direction, the three-pole N pole socket sleeve 23 and the three pole L pole socket sleeve are set on one side of the installation groove 41, the E pole conductive sheet 30, the two pole N pole socket sleeve 22 and the two-pole L-pole socket 13 are located on the other side of the installation groove 41 .

[0027] The E pole socket 32 is arranged on the E pole conductive piece 30, the E pole socket 32 is located between the ...

Embodiment 2

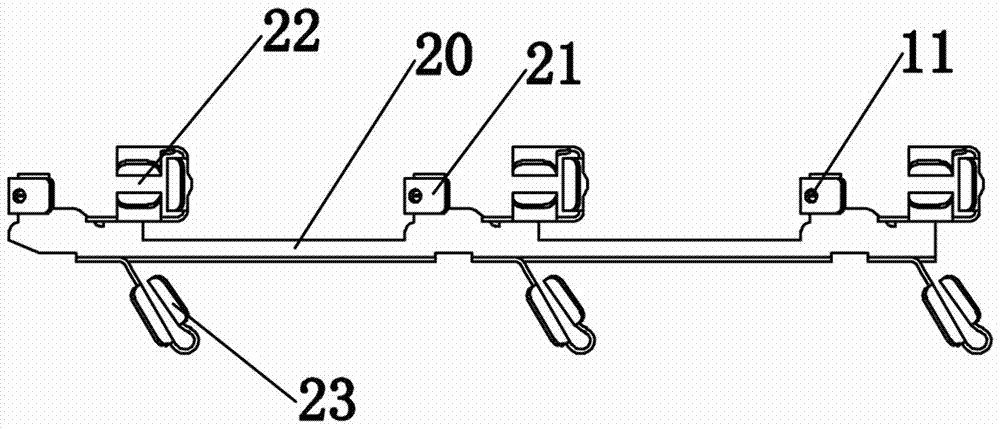

[0035] Embodiment 2. Embodiment 2 is similar to Embodiment 1. The only difference is that: the L-pole conductive strip 10 is arranged in the installation groove 41 and connected to the three-pole L-pole socket sleeves 14 on both sides of the installation groove 41. It is integrated with the two-pole L-pole socket 13, and the N-pole conductive sheet 20 is arranged on the upper side of the installation groove 41. The L-pole conductive sheet 10 straddles the installation groove 41 and connects with the three-pole N-pole on both sides of the installation groove 41. The socket 23 and the two-pole N pole socket 22 are connected into one body.

[0036] The E-pole conductive sheet 30 , the L-pole conductive sheet 10 , and the N-pole conductive sheet 20 are arranged in the base 4 in a left, middle, and right arrangement.

[0037] The base 4 is provided with a positioning column 40, and the corresponding positioning column 40 is provided with a positioning hole 12 on the N pole conducti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com