Bridge frame dedicated for nuclear power and length connecting component thereof

A technology for connecting components and bridges, applied in the direction of pipes/pipe joints/pipes, pipe supports, mechanical equipment, etc., can solve the problems of reducing the strength and bearing capacity of the bridge, the connection between the edge of the ladder and the ladder is not strong enough, and the connection cannot be tightly combined, etc. , to achieve the effect of being conducive to heat dissipation, improving service life and safety performance, and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing.

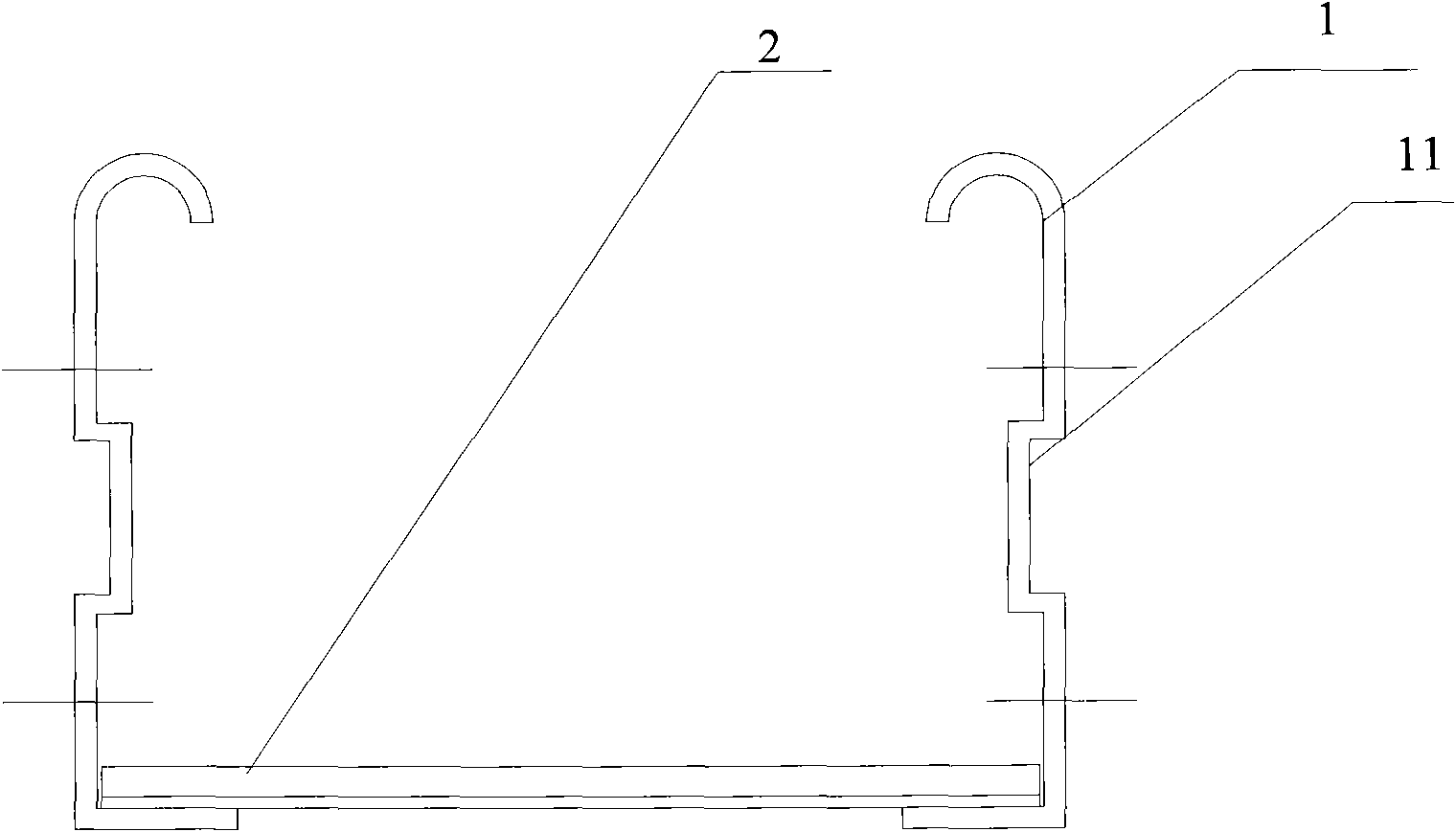

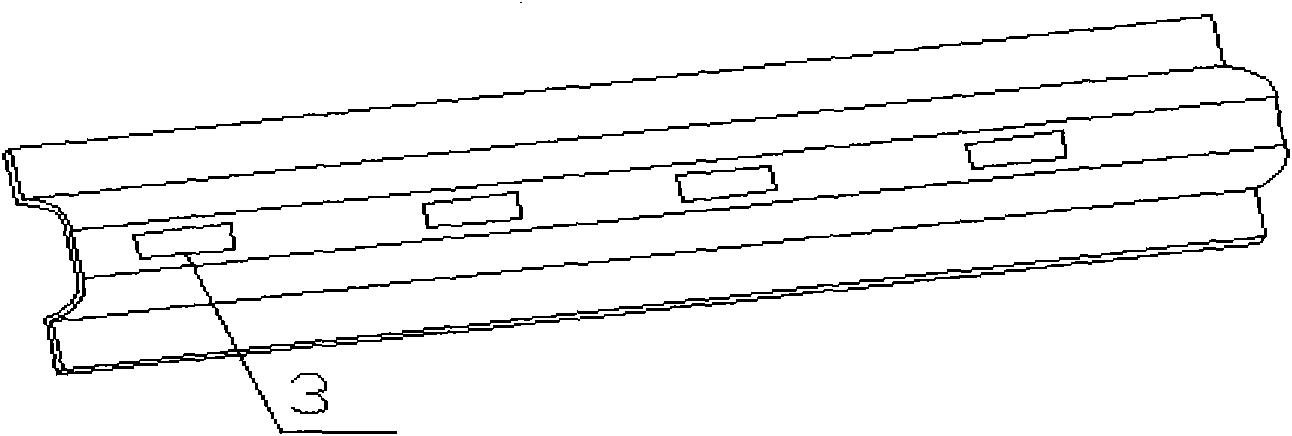

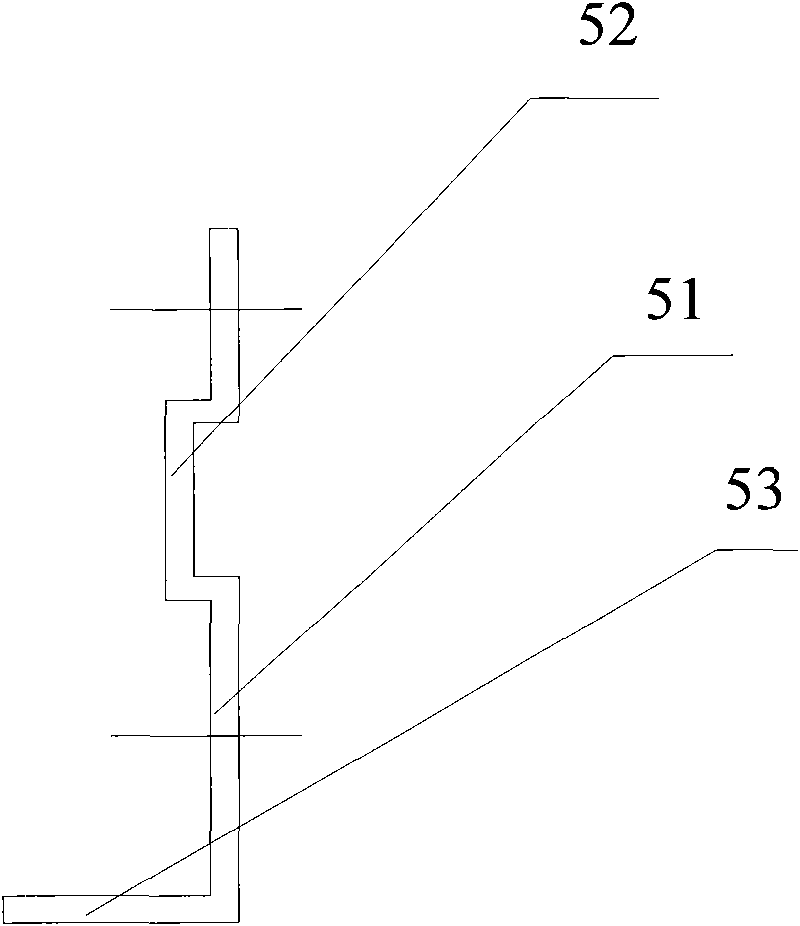

[0019] As shown in the figure, in order to solve the above technical problems, the present invention provides a special bridge for nuclear power, including a ladder side 1 and a ladder bar 2, and the ladder side 1 is fixedly connected to the two ends of the ladder bar 2 by welding or other means. In the shape of a groove, the side of the step edge 1 is provided with a longitudinal groove 11, the shape of the longitudinal groove 11 is not limited, it can be a square groove, or an arc-shaped groove, and the longitudinal groove The number of 11 is not limited, can be designed according to actual needs, can be one, also can be multiple. Since the side of the ladder side 1 is provided with a groove 11, the ladder side of this shape has the characteristics of strong load capacity and high seismic strength, thereby improving the overall strength and strong bearing capacity of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com