Alloy resistor processed by composite material and preparation method thereof

A technology of alloy resistors and composite materials, used in resistor manufacturing, resistors, resistor parts and other directions, can solve problems such as solder loss, unstable resistivity, welding deviation, etc., to reduce equipment investment and solve problems of resistivity. Stable, reduced operator effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings. It should be noted that this embodiment is based on the premise of this technical solution, and provides detailed implementation and specific operation process, but the protection scope of the present invention is not limited to the present invention. Example.

[0029] The invention is a method for preparing an alloy resistance processed by composite materials, the method comprising the following steps:

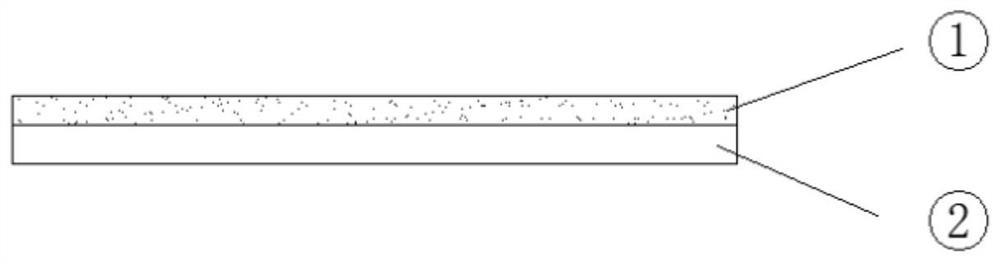

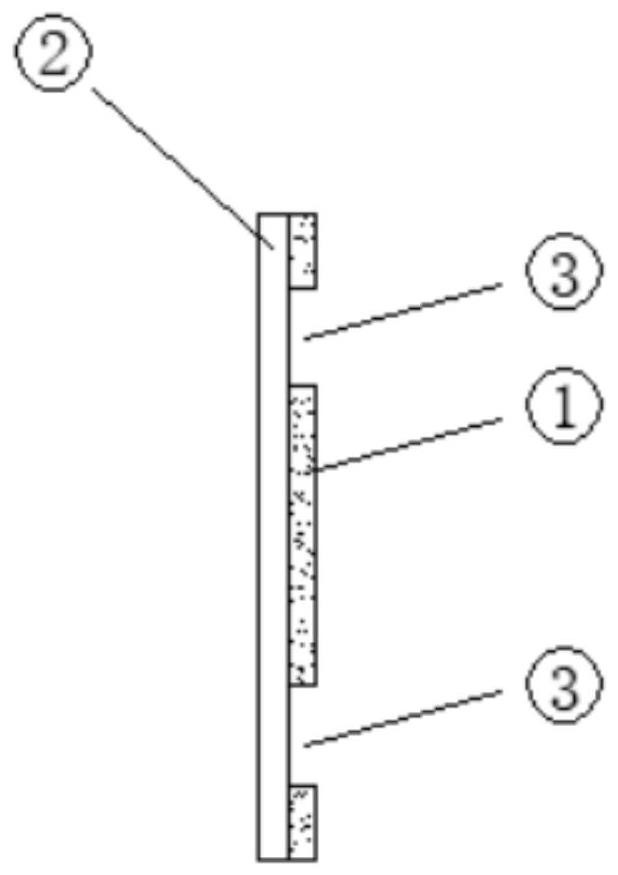

[0030] S1 uses composite materials: red copper and manganese copper / Kama / FeCrAl are composited according to a certain thickness ratio to form a double-layer material;

[0031] S2 grooving: remove the copper material according to the required resistance specification for the double-layer material, and plan two or more grooves;

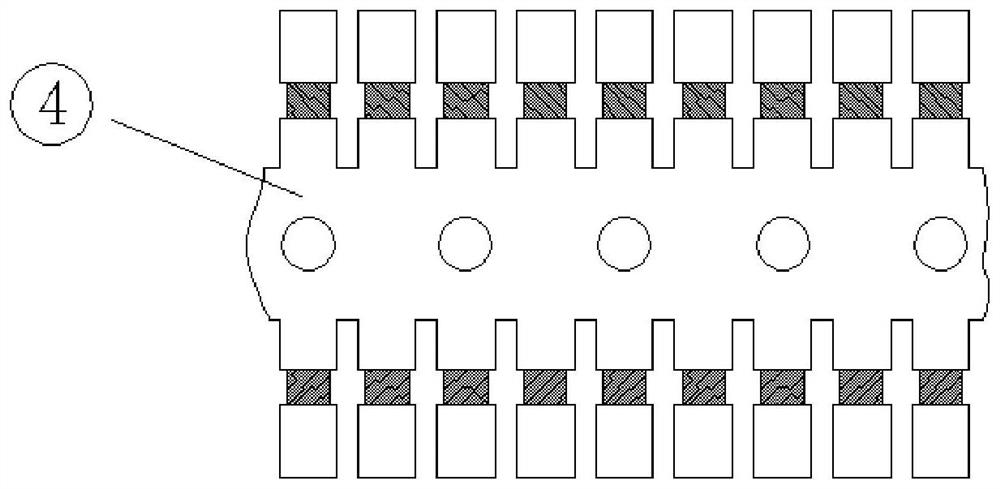

[0032] S3 Stamping into strips: Stamping the double-layer material that has been planed into grooves into strips to form two rows of concave re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com