Technology and device for welding periphery of plate layer of vacuum freeze dryer

A technology of vacuum freeze-drying and welding technology, which is applied in the direction of auxiliary devices, welding equipment, welding equipment, etc. It can solve the problems of difficult control of deformation, scrapping of laminate products, and failure to meet the requirements of edge banding, etc., and achieves a strong practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

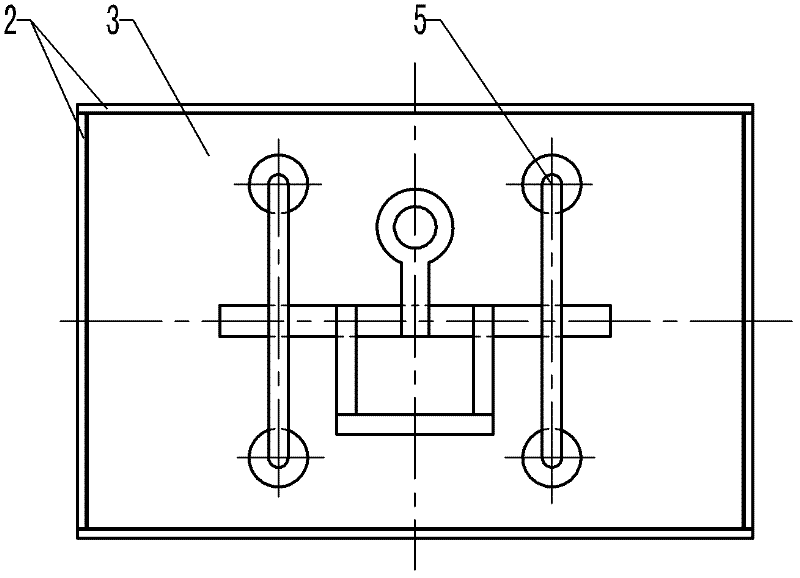

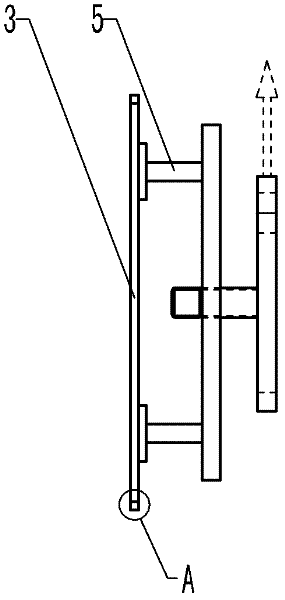

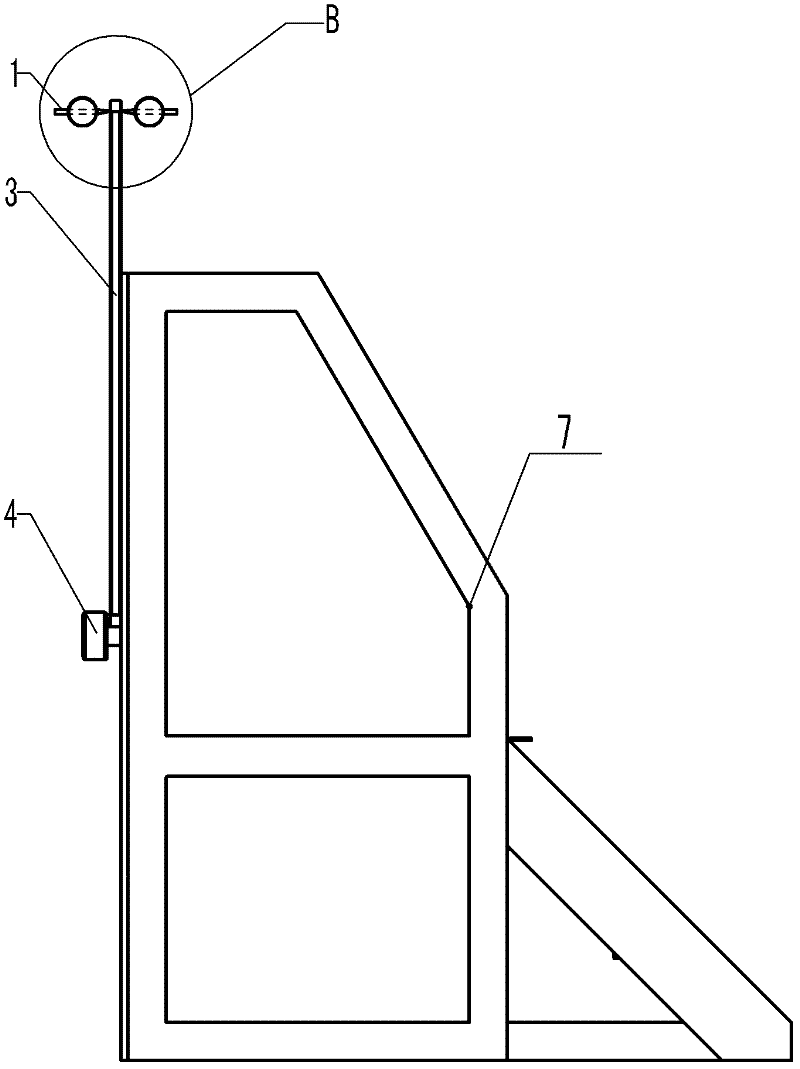

[0036] Refer to attached Figure 1-10 :

[0037] The device for welding around the plate layer of the vacuum freeze dryer mainly includes a bracket 8, a movable workbench 7, a fixed workbench 10, a welding gun moving unit 9, a pressing mechanism 11 and a locking mechanism, and the welding torch moving unit 9 is hoisted on the top of the bracket 8, The fixed workbench 10 is fixedly installed on one end of the bracket 8, the lower end of the movable workbench 7 is installed on the guide rail 14 at the bottom of the bracket 8, and a plurality of supporting wheels 4 are installed on one side of the movable workbench 7 through the mounting holes 6, and the movable workbench A plurality of mounting holes 6 provided on the 7 are threaded holes of uniform specifications, and one end of the supporting wheel 4 is correspondingly provided with external threads.

[0038] The welding torch moving unit 9 includes two welding torches 1 arranged on both sides of the slab 3, a horizontal seam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com