Copper and aluminum transition connection terminal soldering method

A transition connection and terminal technology, applied in the field of copper-aluminum transition clamps, can solve the problems of high cost, high scrap rate, complex process, etc., and achieve the effects of stable performance, good market prospects, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

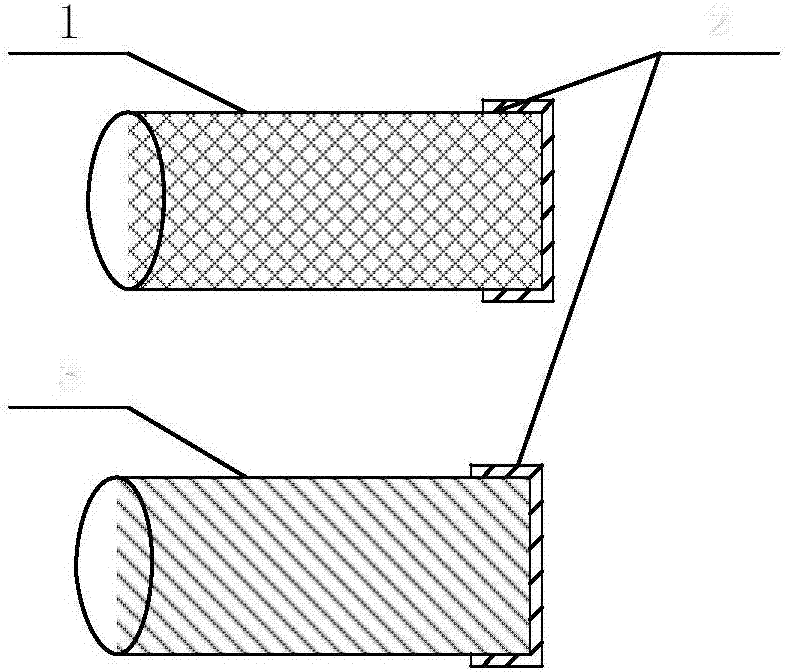

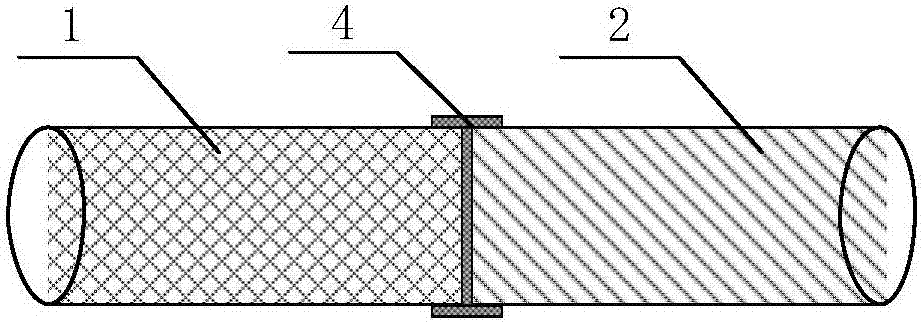

[0026] The present invention will be further described by using examples.

[0027] The aluminum rods and copper rods used in the present invention can have various sizes, and the cross-section is not limited, and there is no limit to the materials used for the aluminum rods and copper rods.

[0028] In the embodiment, the aluminum rod is circular with a radius of 15 mm, and the copper rod is circular with a radius of 15 mm.

[0029] Welding method

[0030] 1. A copper-aluminum transition connection terminal soldering method, characterized in that: the copper-aluminum transition connection terminal soldering method refers to a soldering method for two metals, aluminum and copper, and the method comprises the following steps:

[0031] Step 1: Select the round aluminum rod and copper rod for electrician, select the length and radius respectively according to the needs, and use the grinder to remove the oil and impurities on the surface to be welded;

[0032] Step 2. Put the alu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com