PCB (printed circuit board) design method and PCB

A PCB board and design method technology, applied in the direction of electrical connection printed components, printed circuit components, printed circuits, etc., can solve the problems of failure to effectively improve the problem of virtual soldering, increase product costs, and prone to virtual soldering, etc., to achieve Improve the problem of virtual soldering and air bubbles, eliminate component virtual soldering, and improve product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

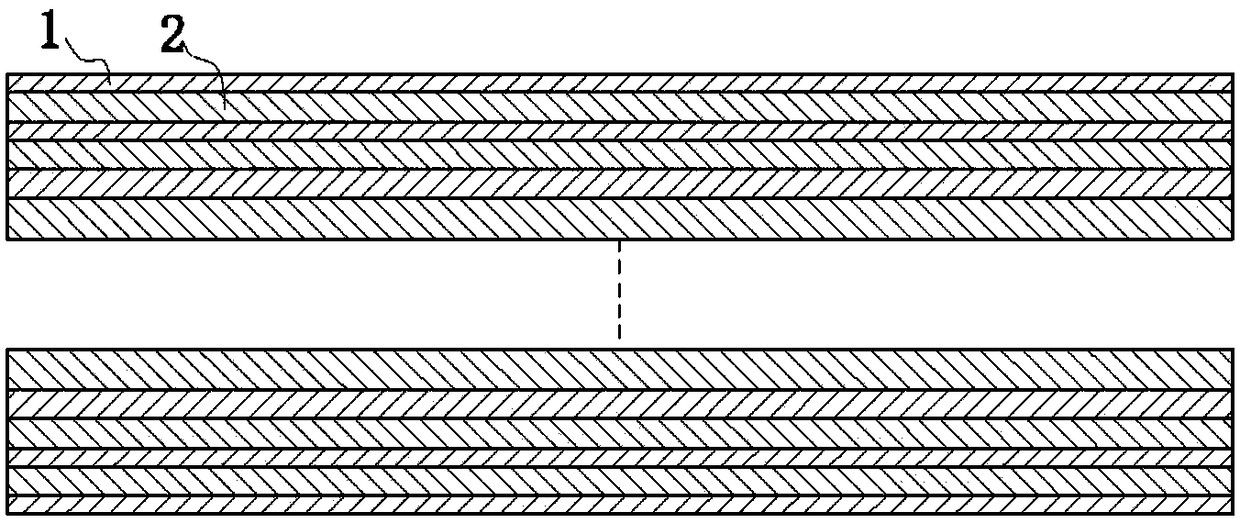

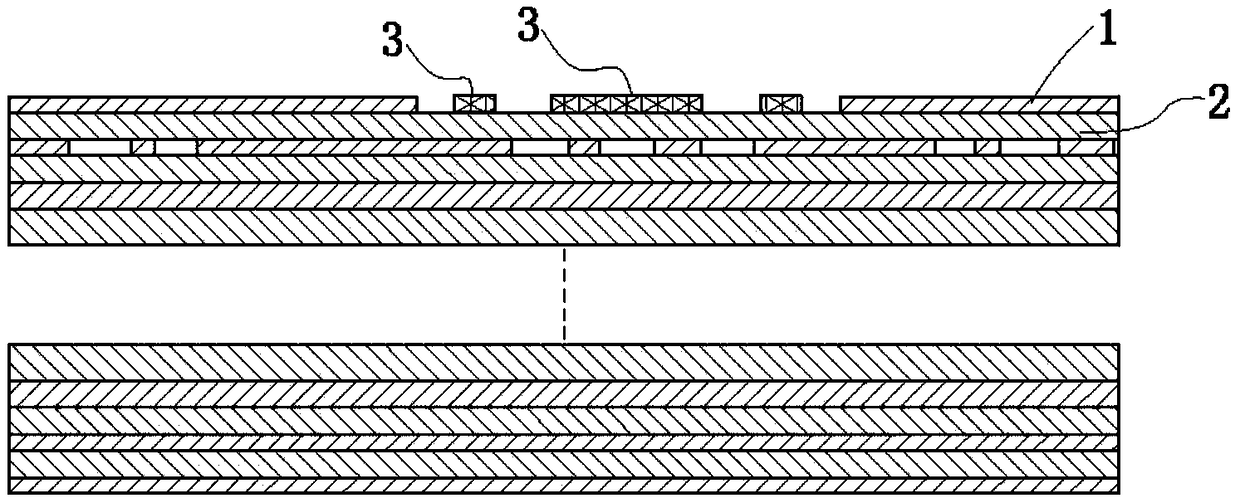

[0037] Step 1: Design the pad 3 corresponding to each pin on the multilayer PCB according to the different pins on the component 4 to be soldered;

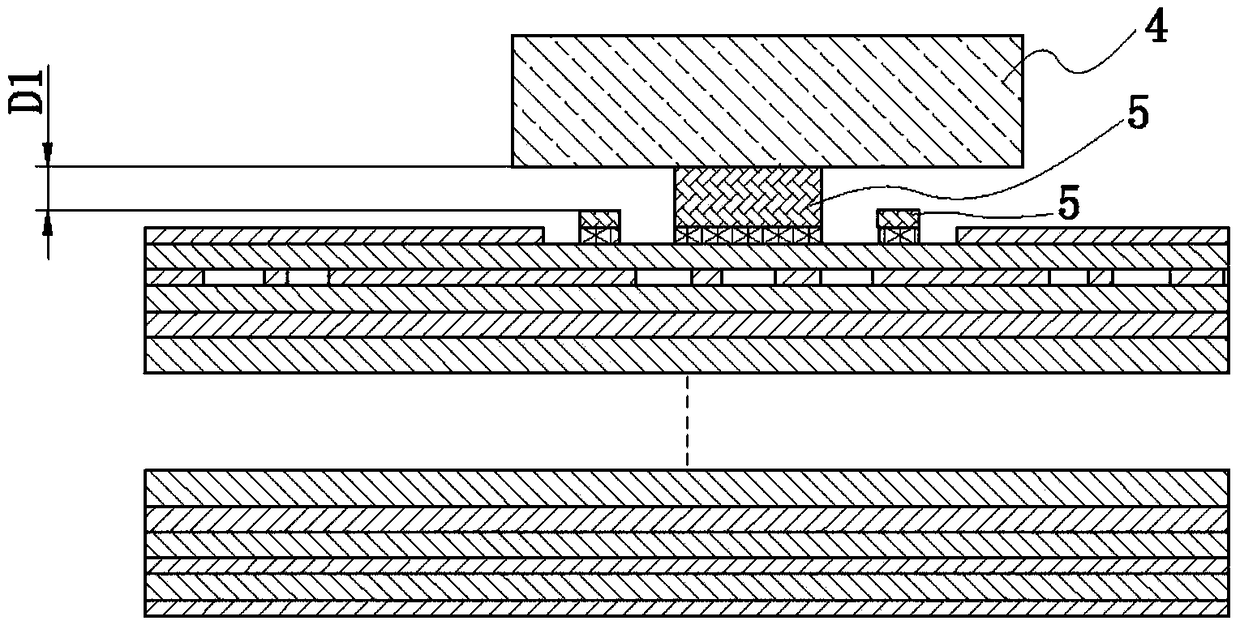

[0038] Step 2: Set the pads 3 corresponding to the pins of different sizes on the copper layer 1 of the different traces of the PCB, and set the pads 3 corresponding to the pins with the smallest size on the surface layer. The pad 3 corresponding to the largest pin is the farthest from the surface. The vertical distance between the inner pad 3 and the PCB surface is D2. The solder paste 5 on the pad 3 is the same as the one on the surface. The thickness difference between the solder paste 5 on the pad 3 is D1, which satisfies 90% D1≤D2≤D1. In this embodiment, D1 is preferably equal to D2, and the solder paste 5 on the inner pad 3 is soldered to the surface layer. The relative height difference of the solder paste 5 on the disk 3 is zero, which more effectively ensures the elimination of the false soldering problem of the component 4;...

Embodiment 2

[0041] This embodiment is basically the same as the first embodiment, but the difference lies in:

[0042] Step 3: The copper layer 1 on the outer layer and the insulating layer 2 corresponding to the pad 3 on the inner layer are provided with openings for exposing the pad 3, and the size of the opening is smaller than the corresponding The size of the pad 3, the horizontal distance from the edge of the opening to the edge of the pad 3 is less than or equal to 2% of the corresponding side length of the pad 3.

[0043] A PCB board design method of the present invention moves the large pad 3 vertically to the inner layer of the multilayer PCB board, and D2 offsets D1, so that the height of the solder paste 5 on the large pad 3 is not too high Effectively eliminate the false soldering of component 4 caused by too much solder paste 5 on the large pad 3, improve the reliability of SMT, improve the problem of false soldering and air bubbles caused by the design of multi-layer PCB board, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com