W-band millimeter wave chip multilayer dielectric substrate

A multi-layer dielectric and millimeter wave technology, applied in the reduction of crosstalk/noise/electromagnetic interference (, printed circuit, radiation element structure, etc., can solve the imbalance of substrate structure and material, solder ball virtual soldering and desoldering, Substrate mechanical warpage and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

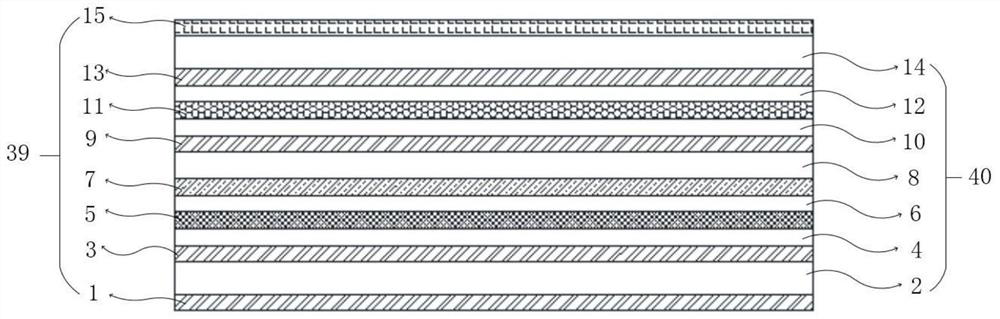

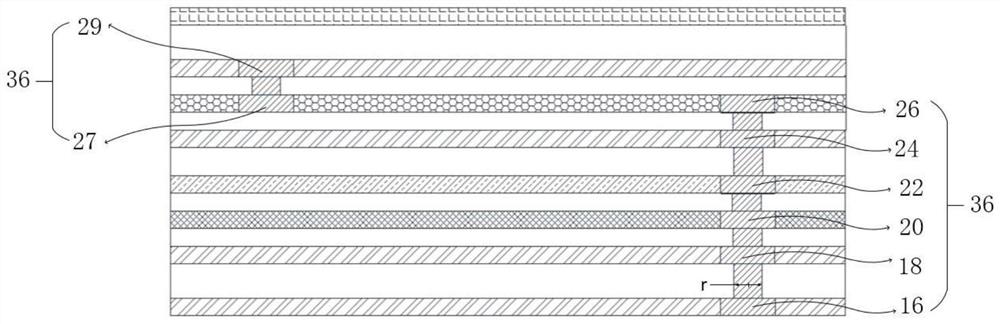

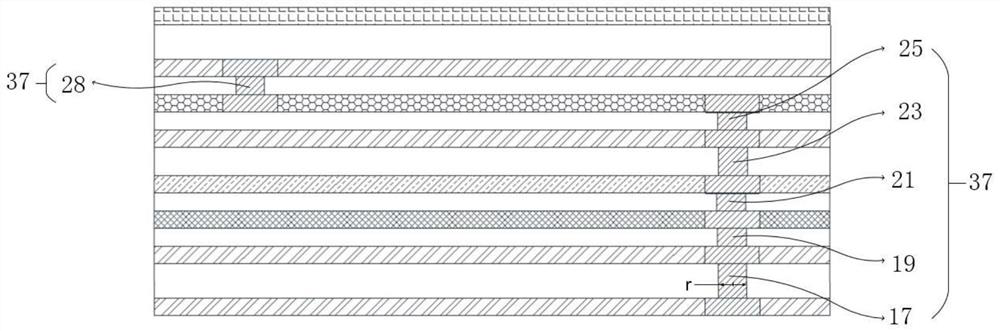

[0048] Such as figure 1 As shown, a cross-sectional view showing a W-band millimeter chip multilayer dielectric substrate provided by the embodiment of the present invention, and the W-band millimeter wave chip multilayer dielectric substrate is alternately arranged by the metal layer 39 and the dielectric layer 40. Specifically includes: the first layer 1, covering the first dielectric layer 2 of the first formation, covering a second formation 3 of the first dielectric layer, covering the second dielectric layer 4 of the second formation, covering the The control layer 5 of the second medium layer covers the third dielectric layer 6 of the control layer, covering the power supply layer 7 of the third dielectric layer, covering the fourth medium layer 8 of the power layer, covering the fourth The third formation 9 of the dielectric layer covers the fifth medium layer 10 of the third formation, covering the radiofrequency layer 11 of the fifth medium layer, covering the sixth medi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com