Power type G9 LED bulb and manufacturing method thereof

A power type, light bulb technology, applied in the direction of damage prevention measures for lighting devices, lighting devices, cooling/heating devices for lighting devices, etc., can solve the problems of G9 small size, high energy consumption, poor heat dissipation, etc., and achieve demoulding production Improve efficiency, reduce heat generation, and ensure life expectancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

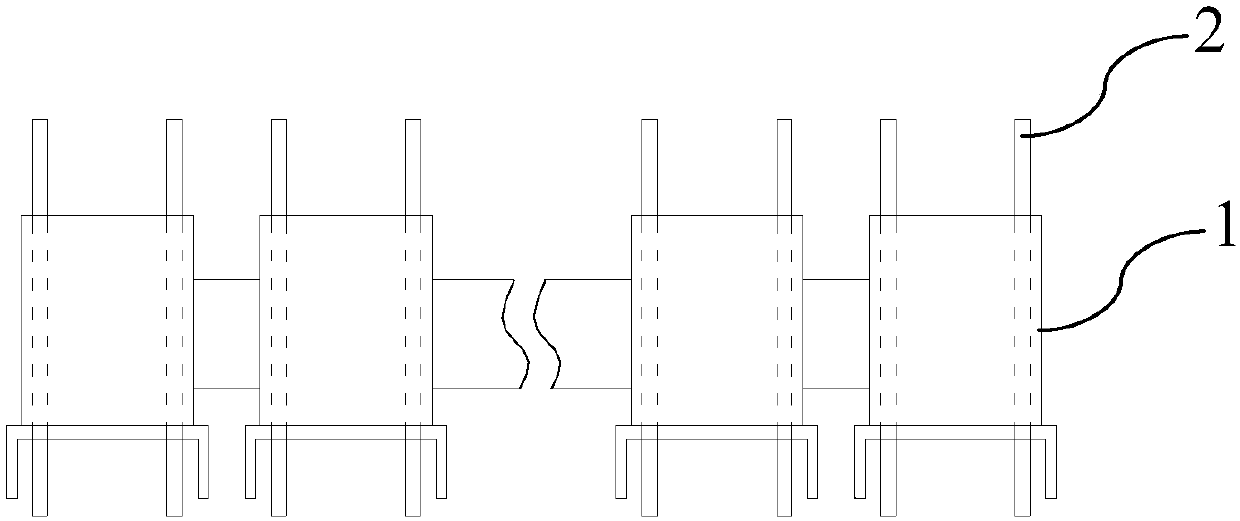

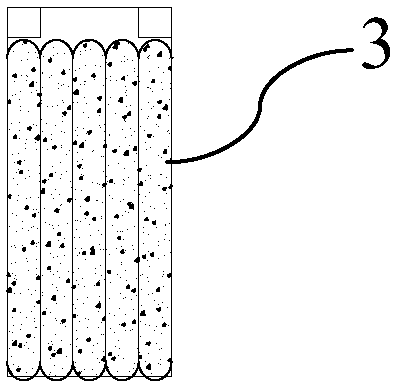

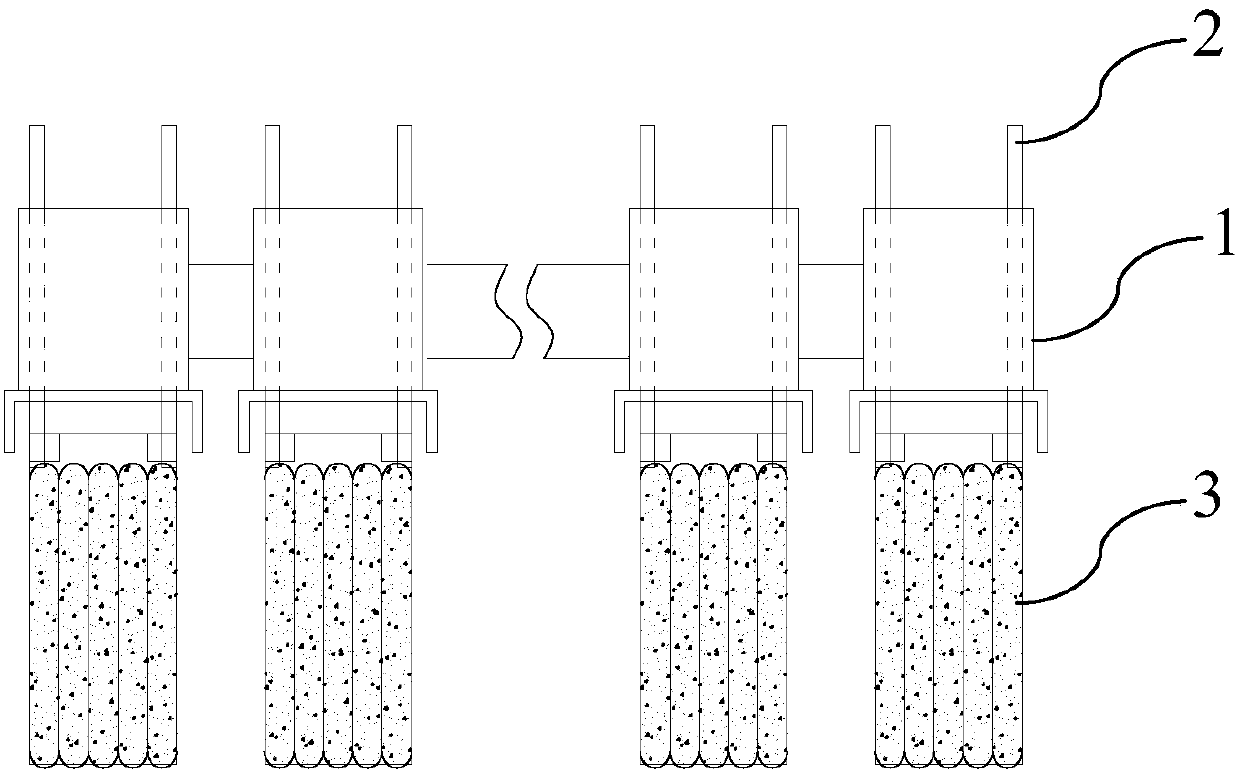

[0032] Such as figure 1 Fix two metal pins 2 on the connecting plate insulating cover 1, figure 2 It is a schematic diagram of the LED light sheet, such as image 3 Connect the positive and negative poles of the LED light sheet 3 to one end of the metal pin respectively, Figure 4 is a schematic diagram of a dedicated mold, such as Figure 5 Inject transparent silica gel 5 in special mold 4, such as Image 6 Insert the whole row of LED light pieces connected with the insulating cover of the connecting plate into the special mold 4 filled with transparent silicone, and bake and cure, so that the transparent silicone 5 is completely combined with the LED light pieces 3 and the insulating cover of the connecting plate 1, and then Demoulding the baked and cured semi-finished products to form a whole row of power type G9 LED bulbs, such as Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com