Axial diode junction box and manufacturing method thereof

A technology of axial diodes and junction boxes, applied in electrical components, photovoltaic modules, photovoltaic power generation, etc., can solve the problems of complicated installation process and high price, and achieve the goal of increasing heat dissipation area, improving power utilization rate and reducing product cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

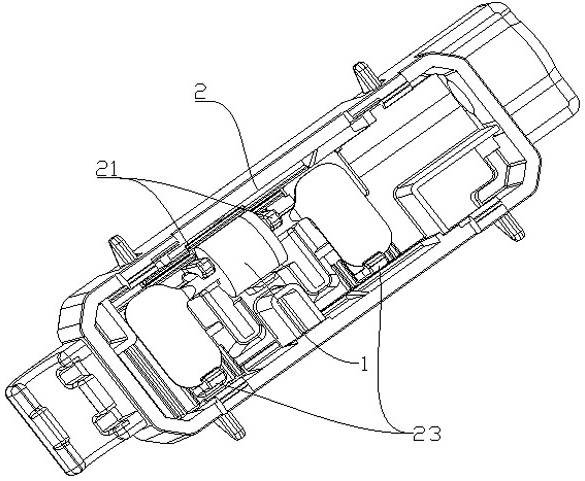

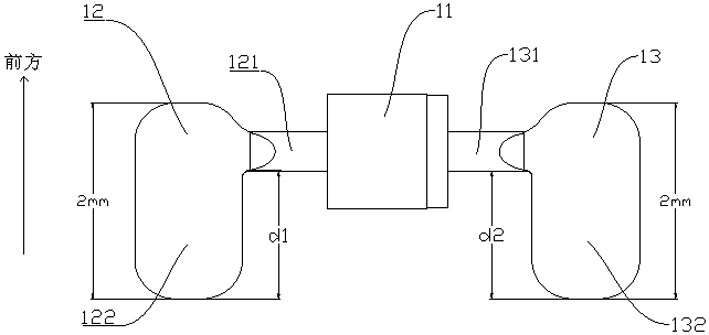

[0039] Such as Figure 1-6 As shown, an axial diode junction box includes an axial diode 1 and a junction box body 2 , and the axial diode 1 is installed inside the junction box body 2 . Axial diode 1 comprises diode body 11, first pin 12 and second pin 13, and one end of diode body 11 is connected with first pin 12, and the other end of diode body 11 is connected with second pin 13; Define diode The direction in which the main body 11 approaches the junction box body 2 is the front. The first pin 12 includes a first connecting portion 121 and a first flat portion 122, one end of the first connecting portion 121 is connected to one end of the diode body 11, the other end of the first connecting portion 121 is connected to the first flat portion 122, and the first connecting portion 121 is connected to the first flat portion 122. Two pins 13 include a second connecting portion 131 and a second flat portion 132, one end of the second connecting portion 131 is connected to the o...

Embodiment 2

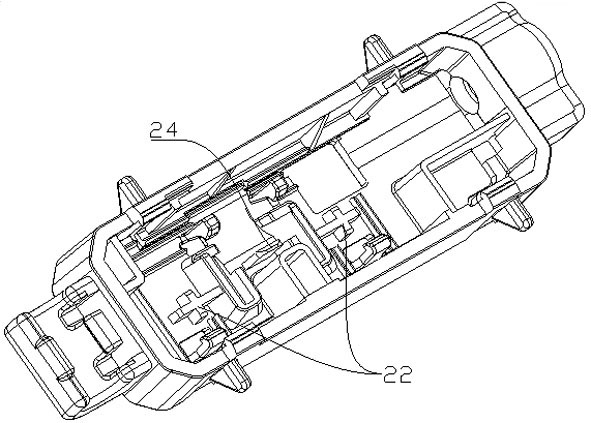

[0046] Such as Figure 7-11 As shown, an axial diode junction box includes an axial diode 1 and a junction box body 2 , and the axial diode 1 is installed inside the junction box body 2 . The axial diode 1 includes a diode body 11, a first pin 12 and a second pin 13, one end of the diode body 11 is connected to the first pin 12, and the other end of the diode body 11 is connected to the second pin 13, defining a diode The direction in which the main body 11 approaches the junction box body 2 is the front. The first pin 12 includes a first connecting portion 121 and a first flat portion 122, one end of the first connecting portion 121 is connected to one end of the diode body 11, the other end of the first connecting portion 121 is connected to the first flat portion 122, and the first connecting portion 121 is connected to the first flat portion 122. The second pin 13 includes a second connecting portion 131 and a second flat portion 132 , one end of the second connecting por...

Embodiment 3

[0053] Such as Figure 12 Shown, a kind of manufacturing method of axial diode junction box comprises the following steps:

[0054] S1: Put the axial diode 1 into the stamping die, bend the first pin 12 of the axial diode 1 first and then press and flatten it to obtain the first flat part 122, and place the second pin of the axial diode 1 13 is first bent and then punched and flattened to obtain the second flat portion 132 .

[0055] Alternatively, put the axial diode 1 into a stamping die, punch and flatten the first pin 12 of the axial diode 1, and then bend the flattened part to obtain the first flat part 122, and place the first pin 12 of the axial diode 1 The second pin 13 is punched and flattened firstly, and then the flattened part is bent to obtain the second flat portion 132 .

[0056] S2: Install the formed axial diode 1 into the junction box body 2, directly weld the cable to the first flat part 122 and / or the second flat part 132, connect the bus bar to the first...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com