Power module structure with vapor chamber heat radiation substrate

A heat dissipation substrate and power module technology, which is applied to semiconductor/solid-state device parts, semiconductor devices, electrical components, etc., can solve the problem of low heat dissipation efficiency of power modules, and achieve the effects of rapid transmission, improved reliability, and efficient heat dissipation structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

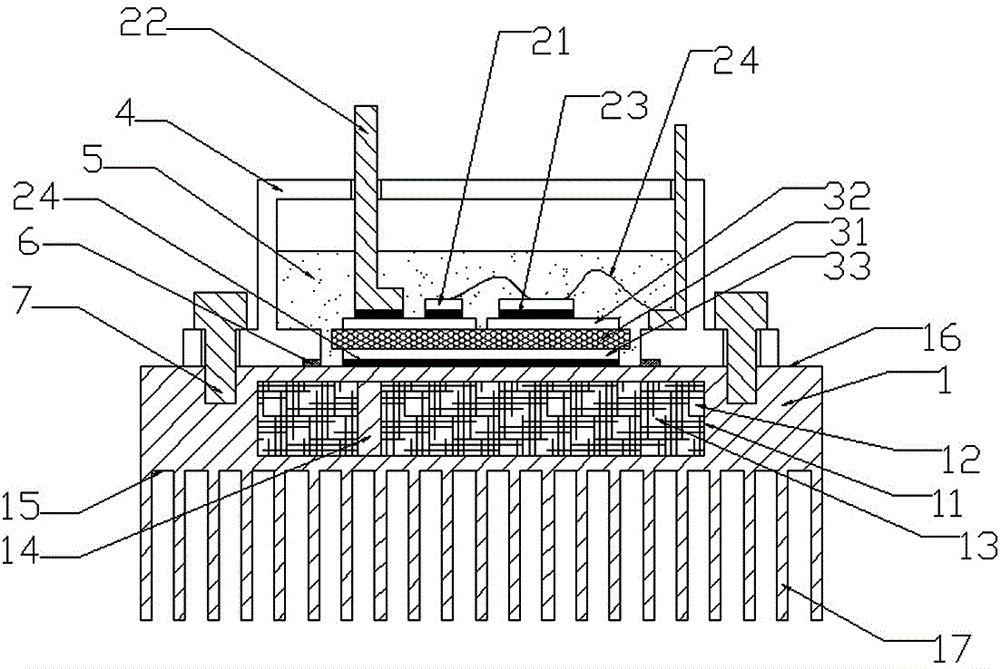

[0021] Example: figure 1 As shown, in the present invention, copper layers are sintered on both sides of the insulating ceramic layer 31 of the copper-clad ceramic substrate, which are divided into an upper copper layer 32 and a lower copper layer 33 . Power devices such as chip 21 and terminal 22 are soldered to the upper copper layer 32 of the copper-clad ceramic substrate through solder 23 , and the chip 21 and terminal 22 form a circuit through the wire 24 and the upper copper layer 32 . The lower copper layer 33 of the copper-clad ceramic substrate is soldered to the upper surface 16 of the heat dissipation substrate of the vapor chamber through the solder 24 . There is a vacuum chamber 11 in the heat dissipation substrate 1 of the vapor chamber, and there are microstructures 13 and several support columns 14 in the vacuum chamber, and a proper amount of heat dissipation medium 12 is injected into the vacuum chamber. The lower surface 15 of the heat dissipation substrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com