Manufacturing method of novel gallium nitride LED (light emitting diode) chip electrode structure

A technology of LED chip and electrode structure, applied in circuits, electrical components, semiconductor devices, etc., can solve problems such as difficulty in heat dissipation, and achieve the effects of solving uneven heat dissipation, increasing heat dissipation area, and improving heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

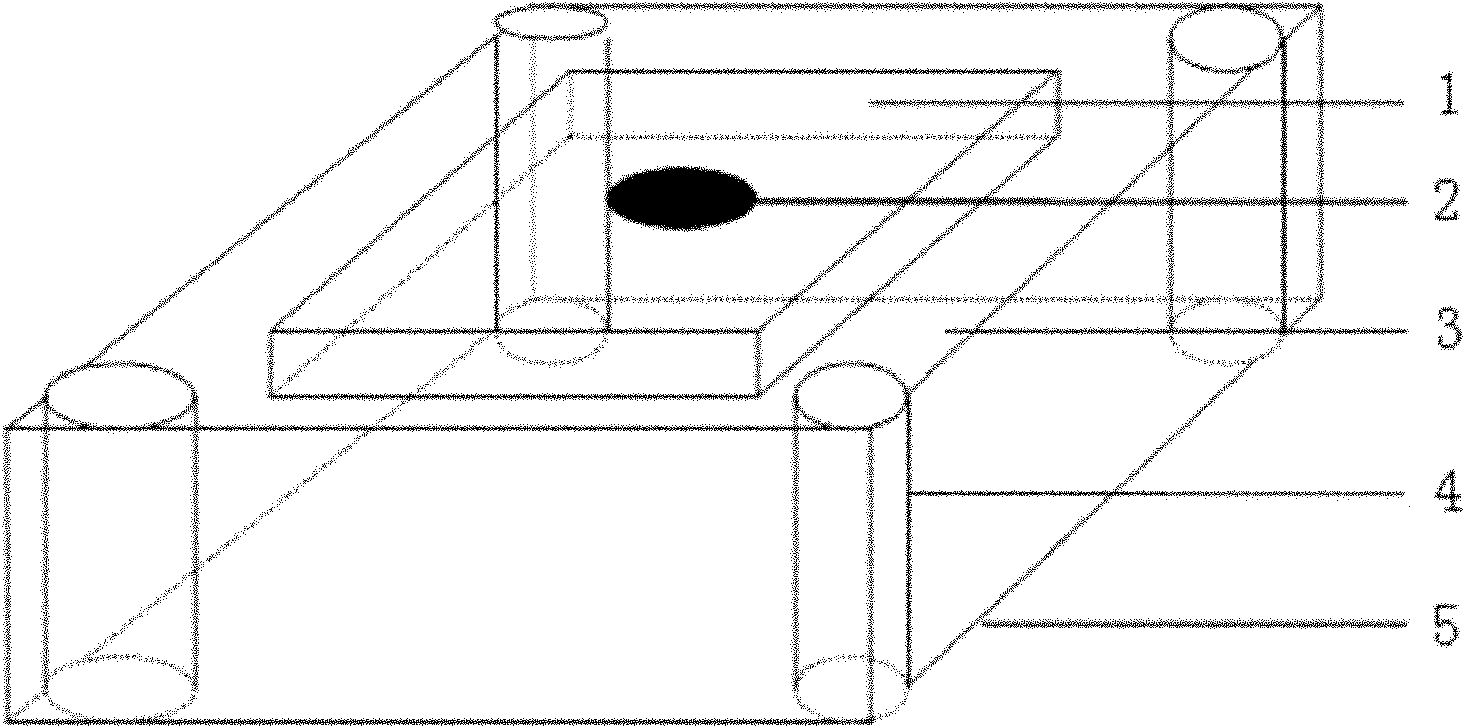

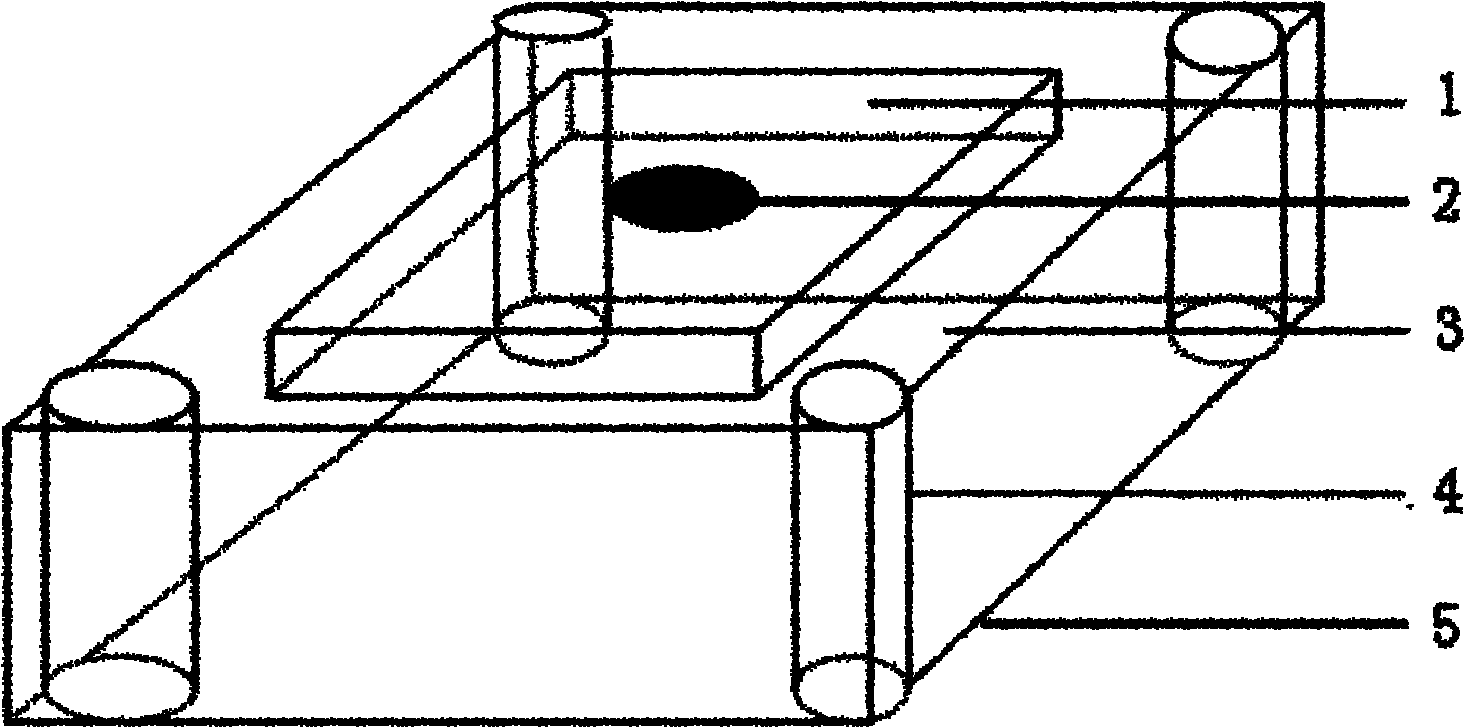

[0016] The specific embodiment of the present invention is as shown in the accompanying drawings.

[0017] First, take an epitaxial wafer with GaN epitaxial layer grown on the sapphire substrate by MOCVD method, and selectively etch and remove the P-type layer in the epitaxial layer by dry etching according to the designed chip electrode structure 1. Exposing the N-type epitaxial layer 3; then forming an ohmic contact between the ITO diffusion layer and the P-type layer on the surface of the P-type epitaxial layer 1 of the epitaxial wafer, and using laser drilling technology at the four corners of the exposed N-type epitaxial layer 3 chip Drill holes perpendicular to the surface of the epitaxial wafer, the depth of the hole is 120um, and the diameter of the hole is 50um; the thickness of the epitaxial wafer after the above operations is reduced to about 120um, so that the hole punched in the previous step becomes a through hole connecting the surface of the substrate and the N-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com