Single-mode high-power vertical-cavity surface-emitting laser based on sic heat sink

A vertical-cavity surface-emitting, high-power technology, which is applied in the field of single-mode high-power vertical-cavity surface-emitting lasers, can solve problems such as increasing the pumping current, increasing the square of heat production, and aggravating the aggregation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

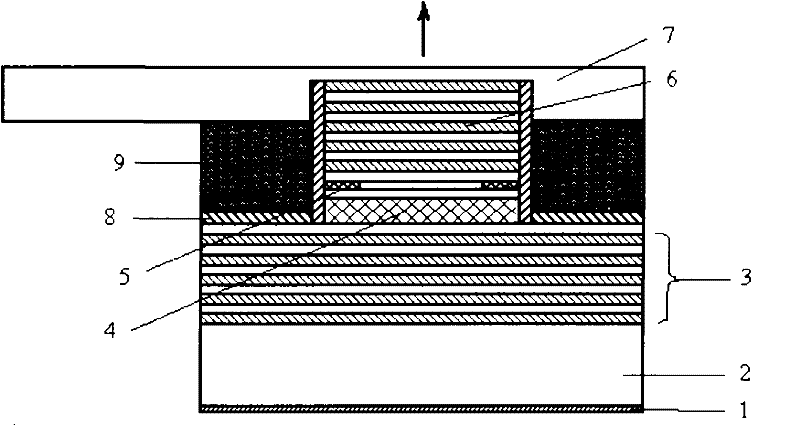

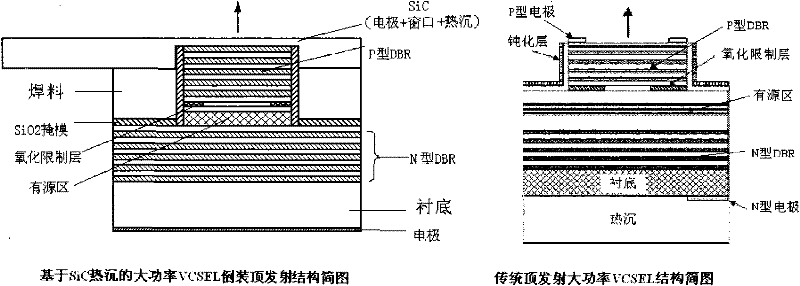

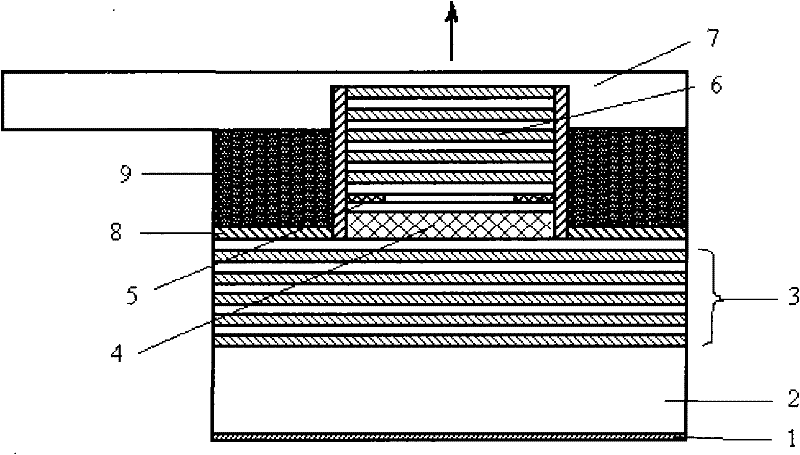

[0013] The modified silicon carbide wafer has high thermal conductivity (up to 500w / mk in the vertical direction), high electrical conductivity, high transmittance in the near-infrared band, and has the characteristics of lattice and expansion coefficient matching with gallium arsenide. It is a high-quality passive heat sink material whose performance is better than that of the currently used oxygen-free copper heat sink and the heat sink materials such as aluminum nitride ceramics and copper-tungsten alloys that are being researched and tested. In our proposed flip-chip top-emission structure scheme using SiC wafers as heat sinks for high-power VCSELs, SiC crystals are used to replace the P electrodes and light exit windows in traditional structural designs, and at the same time, the P-side of the VCSEL epitaxial wafers are directly flipped on On the SiC wafer heat sink, shorten the distance between the active area of the VCSEL epitaxial wafer and the P-type DBR and the SiC ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com