Micro gas sensor recoverable for repeated preparation and preparation method thereof

A gas sensor and heater technology, applied in the direction of material resistance, can solve the problems of reducing production and use costs, prolonging the use time of sensor heating elements, etc., and achieve the effects of improving consistency, long service life, and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

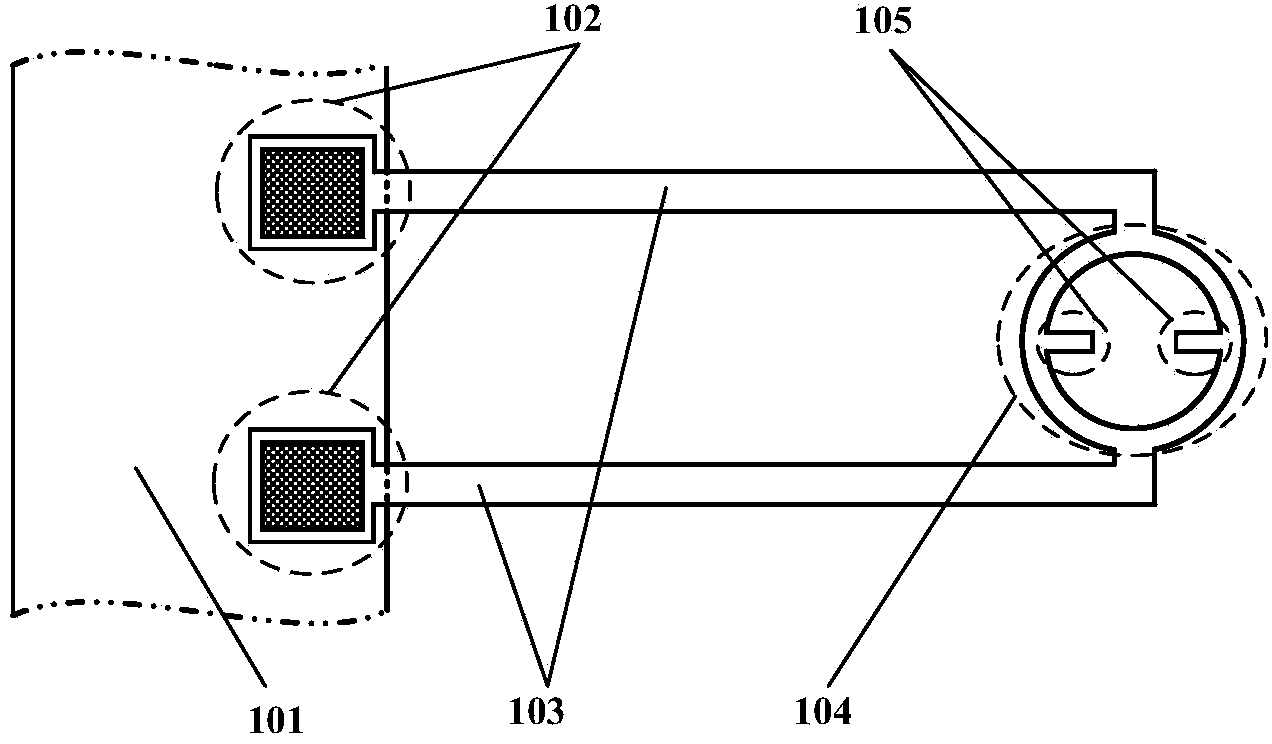

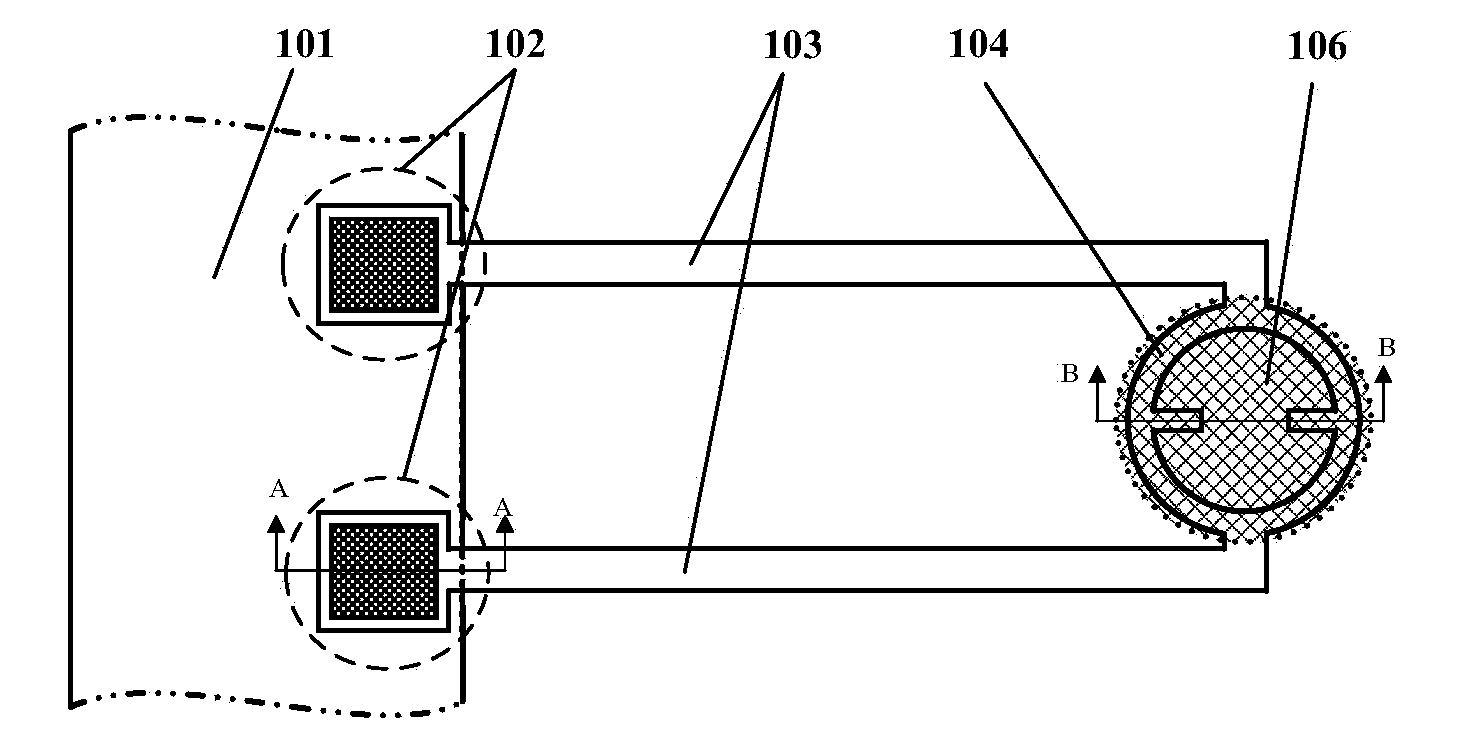

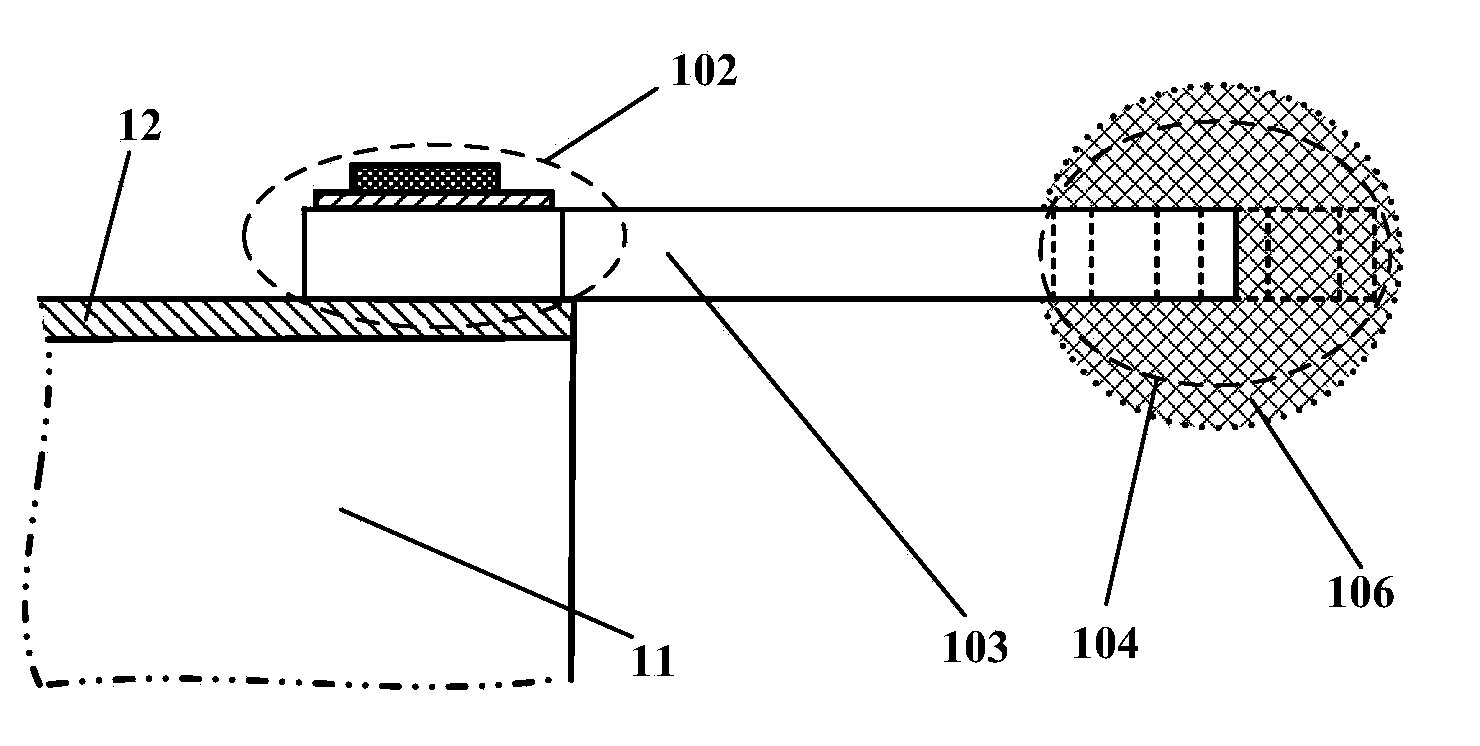

[0027] Example 1: In figure 1 , figure 2 with image 3 Among them, the microgas sensor includes: a silicon support 101, a fixed end 102, a symmetrically arranged silicon cantilever 103, a silicon heater 104, and a catalyst carrier 106; the silicon heater 104 is preferably annular, and the annular The middle of the silicon heater 104 is preferably provided with two symmetrical heat dissipation-supporting silicon blocks 105; the silicon support 101 includes a silicon substrate 11 and a buried layer of silicon oxide 12 disposed on the silicon substrate 11; The silicon cantilever 103 and the silicon heater 104 both include a supporting silicon layer 21 and a silicon oxide layer 23 outside the supporting silicon layer 21; one end of the silicon cantilever 103 is connected to one side of the silicon heater 104, and the other end is connected to the silicon heater 104. The fixed end 102 on the support 101 is connected; the fixed end 102 is arranged on the buried layer silicon oxid...

Embodiment 2

[0040] Embodiment 2: described wire bonding method: make the lead wire of sensor, as Figure 7 As shown, the separated silicon device 110 is fixed on the support plate 107. When fixing, at least the silicon heater 104 and the silicon cantilever 103 are positioned to protrude from the support plate 107. The support plate 107 is provided with a metal electrode 108; the metal lead 109 is connected to The metal electrode 108 on the support plate 107 and the metal layer 22 of the electrical extraction pad Pad on the isolated silicon device 110 of the microgas sensor.

[0041] The first preparation sequence is to first prepare the discrete silicon device 110 by using the preparation method of the separated silicon device; then use the method of the catalyst carrier to wrap the silicon heater and the wire bonding method to complete the first preparation.

[0042] Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com