Intelligent motor controller

A technology of intelligent controllers and control boards, applied in the direction of electric solid-state devices, circuits, electrical components, etc., can solve the problems that the controller cannot withstand large current output, the power of the motor controller decreases, and the temperature of the motor controller is high, so as to improve heat dissipation effect, flow rate increase, effect of enhanced heat convection intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

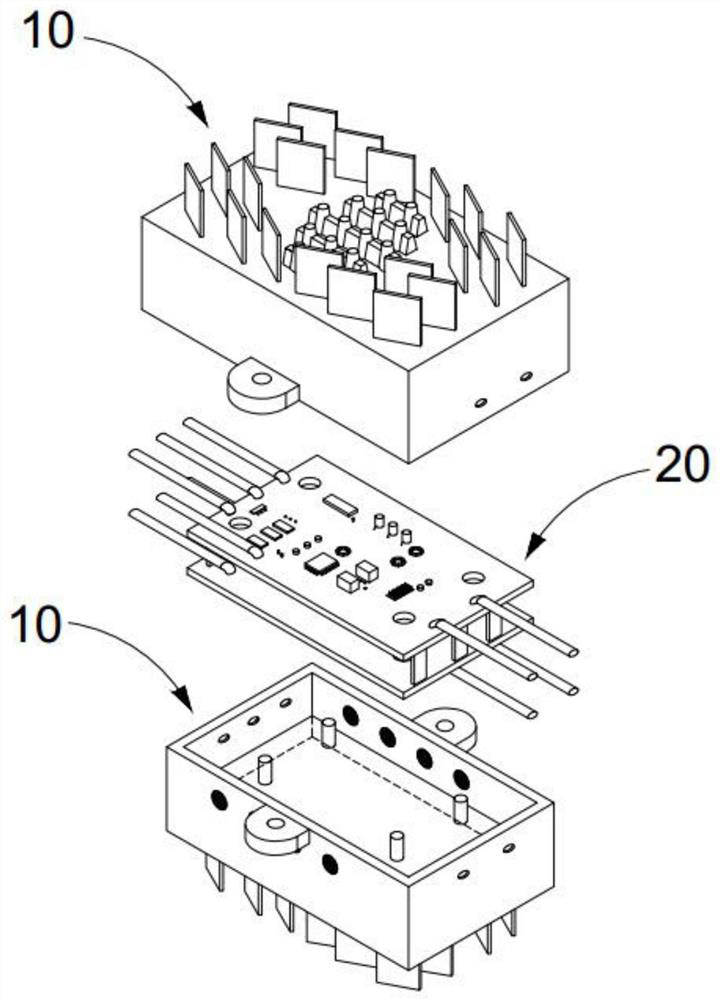

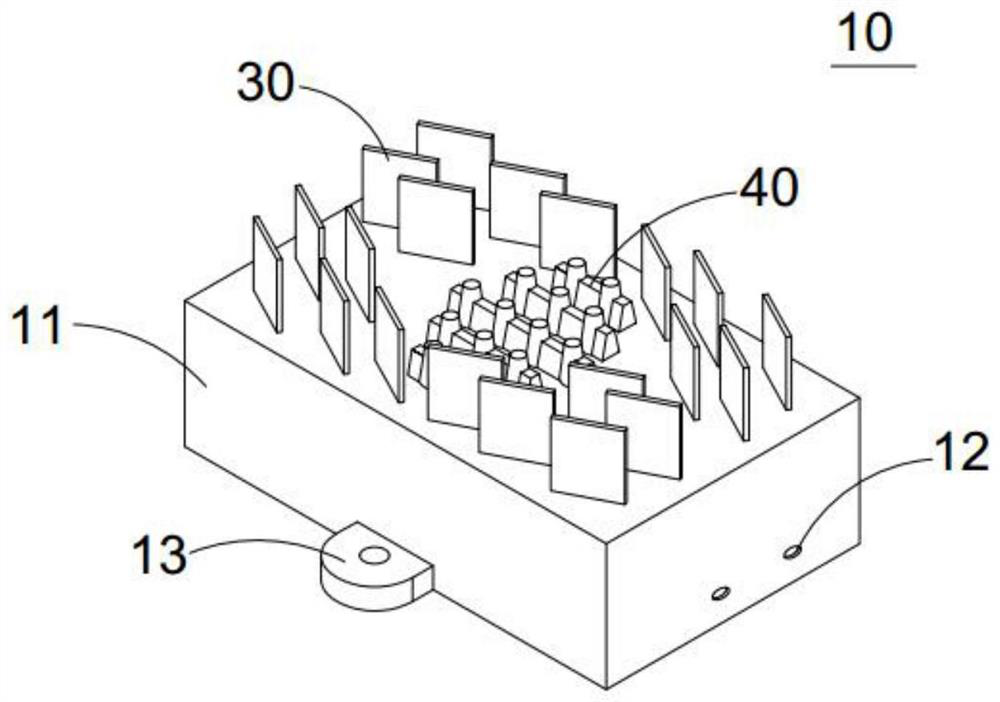

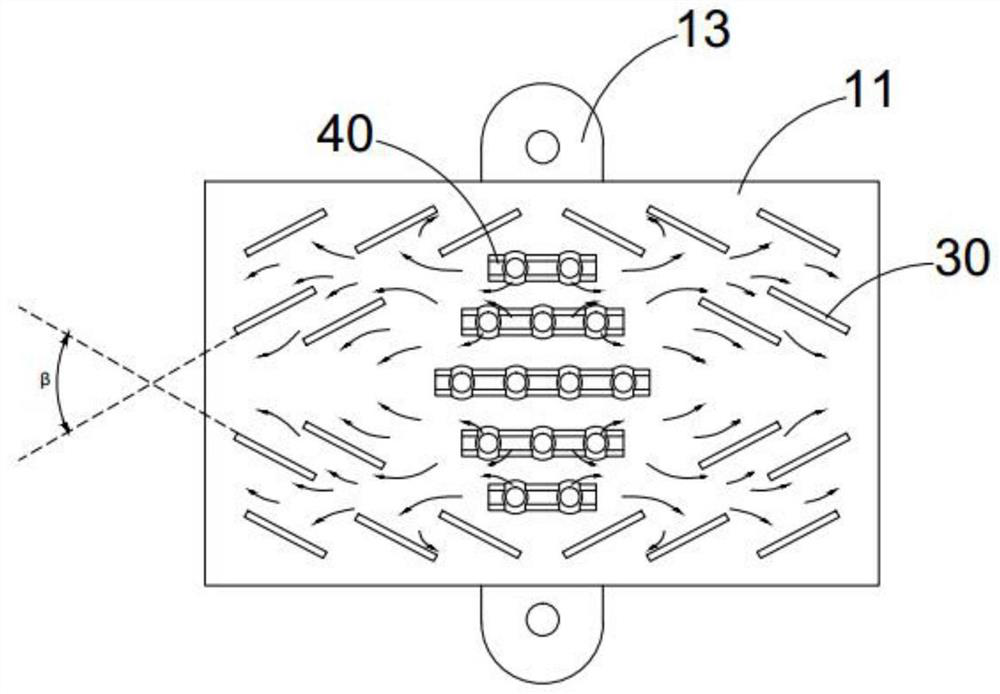

[0047] See attached Figure 1-9As shown, a motor intelligent controller includes: a control board 20, the upper and lower ends of the control board 20 are equipped with a heat sink 10, the heat sink 10 includes a heat dissipation housing 11, and the control board 20 is located in the heat dissipation housing 11; 11 has a heat dissipation surface, the middle part of the heat dissipation surface is provided with a heat dissipation strip 40, and the two sides of the heat dissipation strip 40 in the middle part of the heat dissipation surface are arranged at intervals horizontally and the length of the heat dissipation strips 40 is gradually reduced, and the heat dissipation surface is provided with heat dissipation fins 30 arranged vertically to the heat dissipation surface , the heat dissipation fins 30 are symmetrically arranged on the side of the heat dissipation strip 40, and are inclined relative to the heat dissipation strip 40. The heat dissipation fins 30 are used to guide...

Embodiment 2

[0078] This embodiment is optimized as follows on the basis of Embodiment 1: the heat dissipation surface has a symmetrical center line of the long side and a symmetrical center line of the short side, and the cooling strip 40 is arranged parallel to the symmetrical center line of the long side or the symmetrical center line of the short side. The sheet 30 has an included angle with the symmetrical center line of the long side or the symmetrical center line of the short side, and the included angle is an acute angle. There is no limit to the included angle of the radiating fins 30 oppositely arranged on both sides. By limiting the relative included angle of the radiating fins 30, the arrangement scheme of the radiating fins 30 is optimized, so that the airflow passing through the heat-dissipating surface in different directions can effectively make the airflow in the middle of the heat-dissipating surface. A certain aggregation effect is formed, and the upward flow rate of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com