Multi-chipset high-power LED encapsulation structure

An LED packaging, high-power technology, applied in electrical components, electric solid-state devices, circuits, etc., can solve the problem of heat dissipation of high-power LED lighting modules, and achieve excellent heat dissipation, reduced thermal resistance, and reduced costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

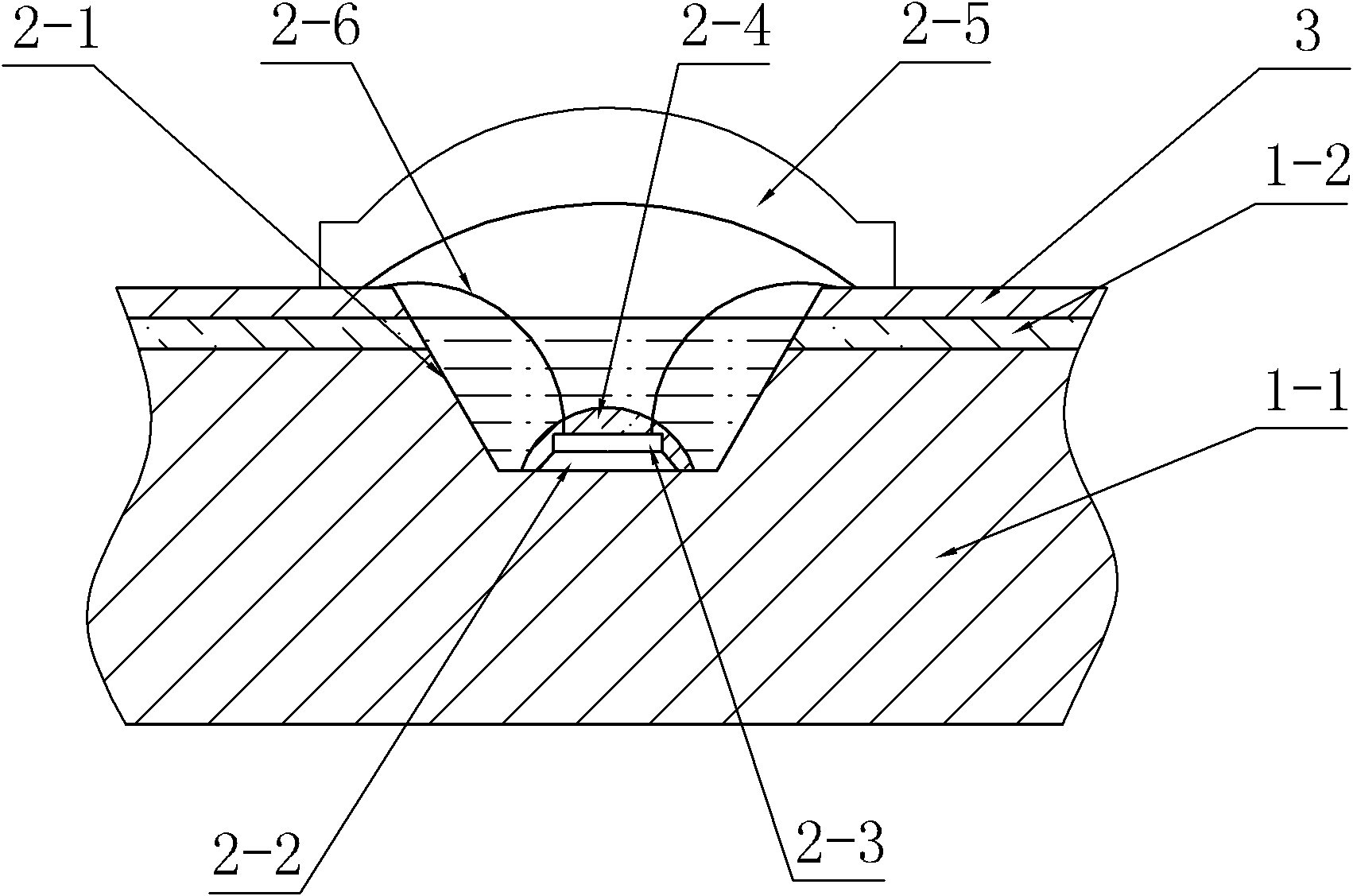

[0021] Specific implementation mode one: the following combination Figure 1 to Figure 3 Describe this embodiment, this embodiment is made up of substrate, a plurality of encapsulating units and circuit wire 3,

[0022] A plurality of packaging units are evenly distributed on the front of the substrate, and circuit wires 3 are printed on the front of the substrate.

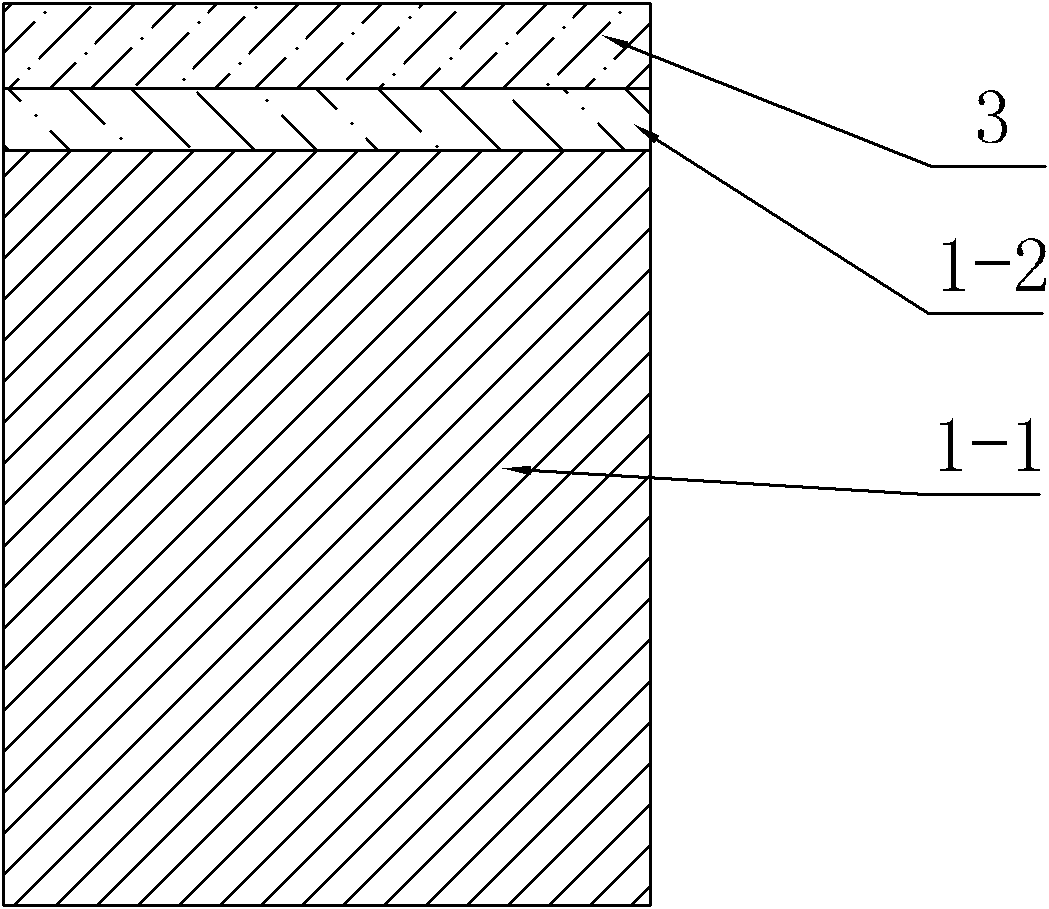

[0023] The substrate is composed of a lower copper heat dissipation substrate 1-1 and an upper insulating layer 1-2,

[0024] Each packaging unit is composed of a reflective cup 2-1, a bonding layer 2-2, an LED chip 2-3, a fluorescent powder 2-4, a silicone lens 2-5 and a gold wire 2-6 for ball bonding,

[0025] The reflective cup 2-1 is opened on the front of the substrate, and the center of the cup bottom of the reflective cup 2-1 is eutectically bonded to the LED chip 2-3, and the upper surface of the LED chip 2-3 is coated with phosphor powder 2-4. The reflective cup 2-1 is filled with silica gel to fix the ...

specific Embodiment approach 2

[0028] Specific implementation mode two: the following combination Figure 2 to Figure 4 Describe this embodiment, this embodiment is made up of substrate, a plurality of encapsulating units and circuit wire 3,

[0029] A plurality of packaging units are evenly distributed on the front of the substrate, and circuit wires 3 are fixed on the front of the substrate.

[0030] The substrate is composed of a lower copper heat dissipation substrate 1-1 and an upper insulating layer 1-2,

[0031] Each packaging unit is composed of a reflective cup 2-1, a bonding layer 2-2, an LED chip 2-3, a fluorescent powder 2-4, a silicone lens 2-5 and a gold wire 2-6 for ball bonding,

[0032] The reflective cup 2-1 is opened on the front of the substrate, and the center of the cup bottom of the reflective cup 2-1 is eutectically bonded to the LED chip 2-3, and the upper surface of the LED chip 2-3 is coated with phosphor powder 2-4 to reflect light. The cup 2-1 is filled with silica gel, and th...

specific Embodiment approach 3

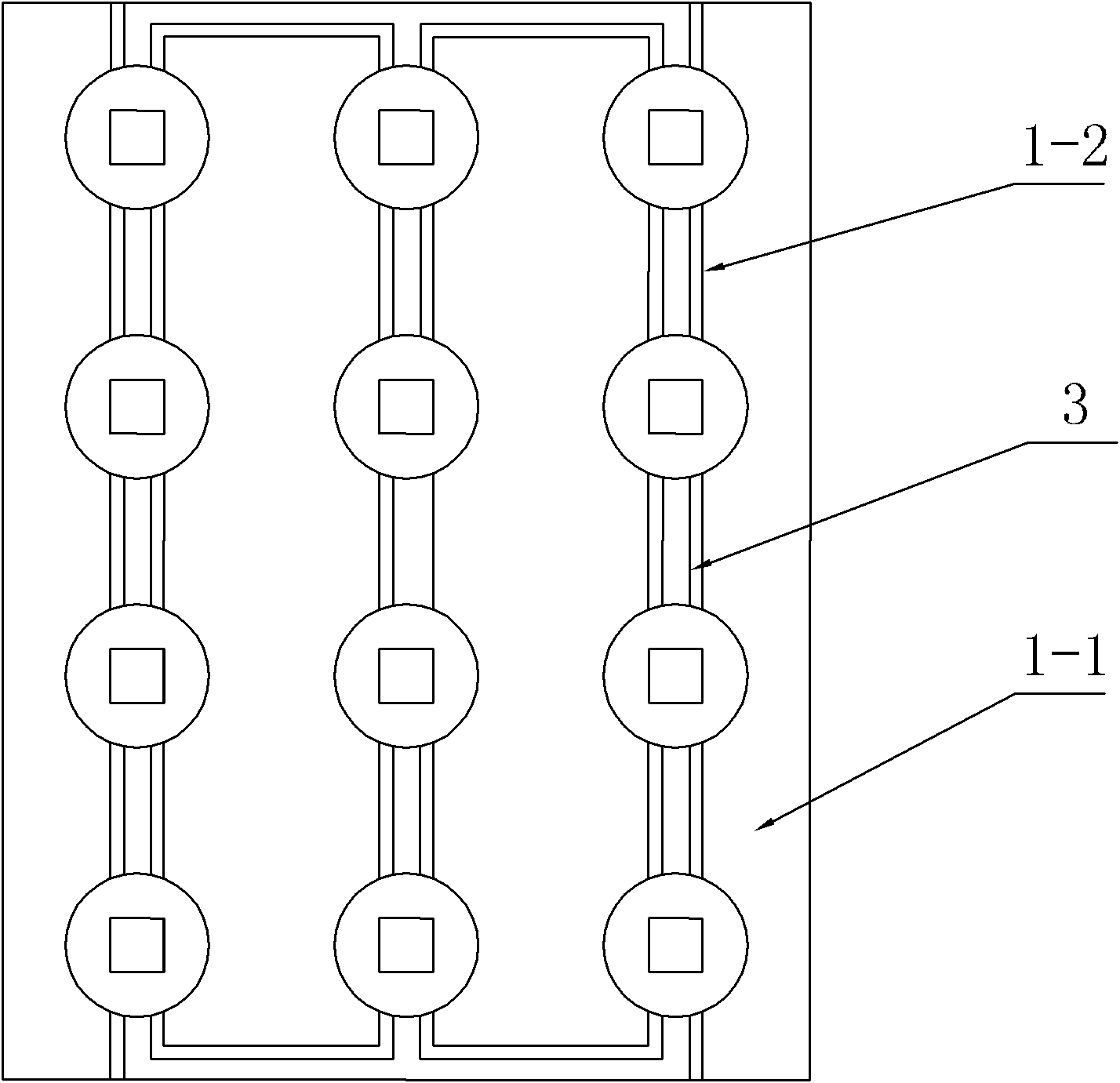

[0035] Specific implementation mode three: the following combination figure 2 This embodiment is described. This embodiment is a further description of Embodiment 1 or 2. The plurality of packaging units are arranged in a matrix on the substrate, and the LED chips 2-3 of all the packaging units in the same row are connected in series to form an LED. groups, multiple LED groups are connected in parallel. Other compositions and connections are the same as those in the first or second embodiment.

[0036] In the matrix arrangement structure of the packaging units described in this embodiment, the distance between them can be controlled by the principle of optical optimization, so as to ensure that the light emitted by the plurality of LED chips 2-3 is uniform.

[0037] figure 2 As shown, the position of each reflector 2-1 is determined according to certain rules, and each reflector 2-1 is packaged with a high-power LED chip 2-3, and each row of four LED chips 2-3 passes throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com