Spherical bowl seat with steel frame net structure

A net structure and bowl seat technology, which is applied in the direction of building construction, construction, etc., can solve the problems of steel frame structure rust damage, collapse accidents, heavy loads, etc., and achieve the effect of easy welding, not easy to desoldering, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

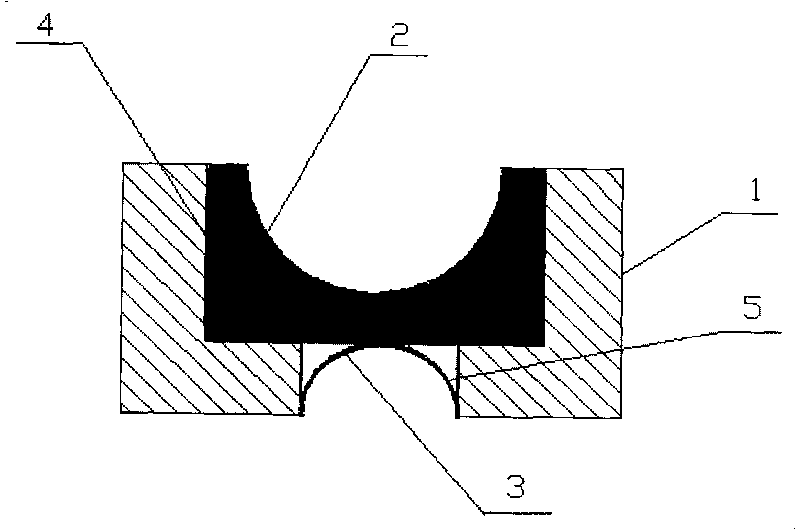

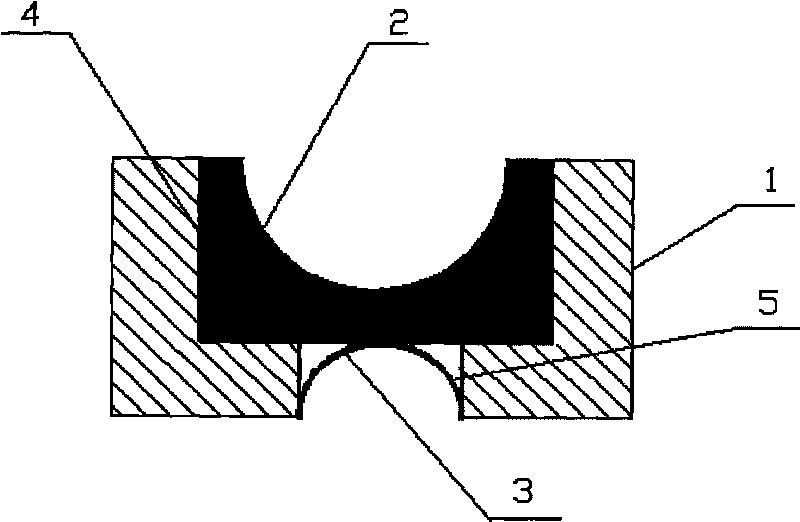

[0008] Use the steel plate (1) to process it into the required block shape, reinforce and weld the outer wall of the large ball seat (4) and the outer wall of the small ball seat (5) on the basis of the block shape of the steel plate (1), and process the large ball seat according to actual needs Bowl seat (2) and small ball bowl seat (3). According to the needs of the structure and the bowl seat, when the steel frame net structure is connected to each other, as long as the large bowl ball and the large ball bowl seat (2), the small bowl ball and the small ball bowl seat (3) are welded to each other and get final product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com