Elastic supporting structure of drying cylinder

A technology of elastic support and drying cylinder, applied in the field of mechanical equipment, can solve the problems of abnormal roundness of rolling rings, equipment damage, de-soldering of pad iron and rolling ring, etc., and achieve the effect of ensuring normal operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

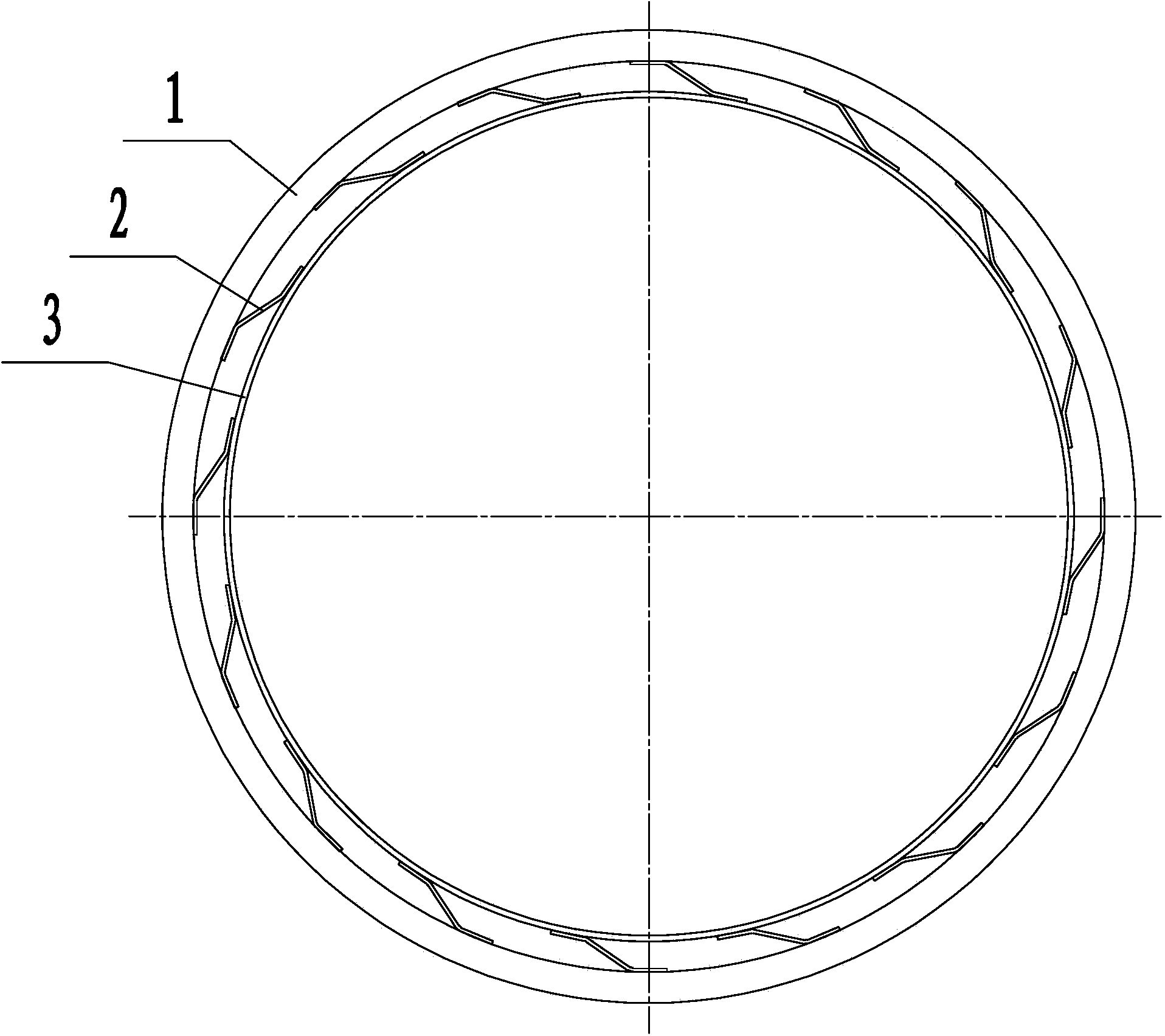

[0009] Such as figure 1 As shown, it includes a rolling ring 1, an elastic plate 2 and a drying cylinder 3.

[0010] The bottom surface of the elastic plate 2 is welded on the drying cylinder 3, and the top surface is welded on the rolling ring 1, the elastic plate 2, the drying cylinder 3 and the rolling ring 1 are combined into one, and the external driving transmission rolling ring 1, Thereby the drying cylinder 3 is driven to rotate.

[0011] Working process and working principle of the present invention

[0012] Since the drying cylinder 3 needs to be heated to a relatively high temperature, it will often expand with heat and contract with cold after running for a long time.

[0013] It is not easy to cause de-soldering between the elastic plate 2 and the rolling ring 1. At the same time, because the elastic plate 2 is stretchable, when the dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com