Machining process of high-wear-resistance alloy cutter

A processing technology, alloy knife technology, applied in the field of high wear-resistant alloy knife processing technology, can solve the problems of affecting mechanical operation efficiency, economic benefits, loss of wear resistance of the tool, waste of knife body materials, etc., to reduce replacement and avoid Downtime maintenance, the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Below in conjunction with embodiment, further illustrate the present invention.

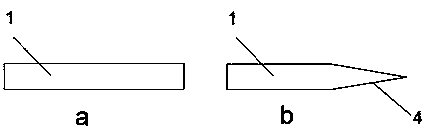

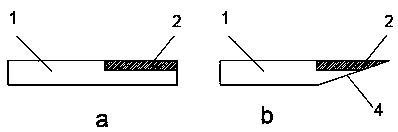

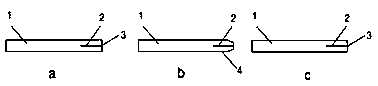

[0041] see figure 1 It can be seen that the cutter body 1 of the prior art does not have the alloy layer 2, and the blade surface of the cutter body 1 is sprayed with wear-resistant materials, and the wear-resistant abrasive grain layer is brazed to improve the wear resistance of the cutter.

[0042] After the surface treatment of the surface blade, the surface has a certain sharpness and increased wear resistance, but the problem is that the layer thickness of the above surface treatment is relatively thin, generally 20-40um, and the above surface treatment layer is distributed on both sides of the knife. One side, during continuous work, once the thinner coating or abrasive grain layer wears out, the tool loses its wear resistance; in addition, the above-mentioned coating only solves the wear resistance of the tool surface and affects the sharpness of the knife body 1 edge. , does not h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com