Scaffold production process

A production process and scaffolding technology, which is applied in the field of scaffolding, can solve the problems of protective net damage, poor contact parts, net easy desoldering, etc., and achieve the effects of not easy desoldering or damage, high fixing strength, and improved utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings.

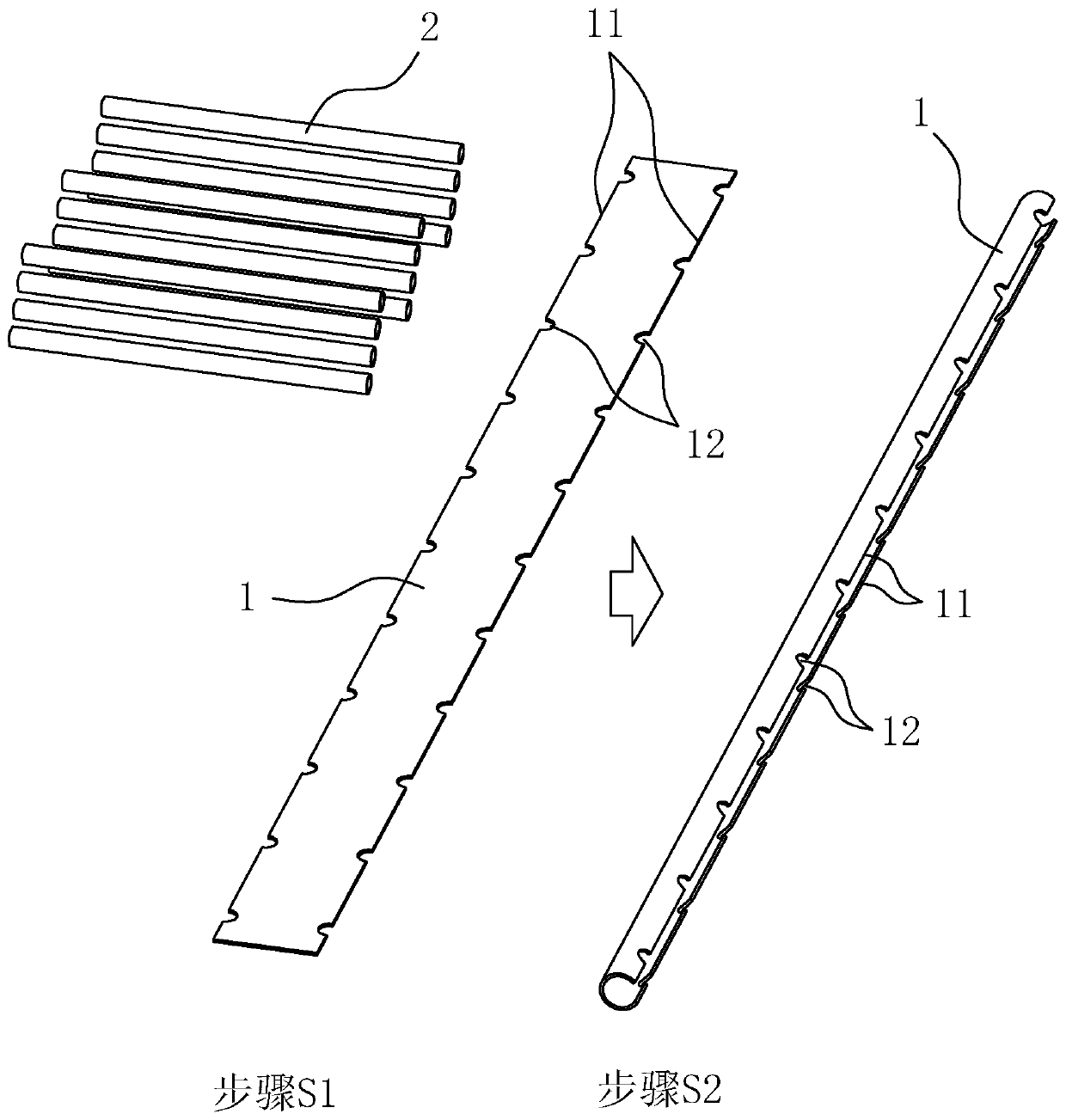

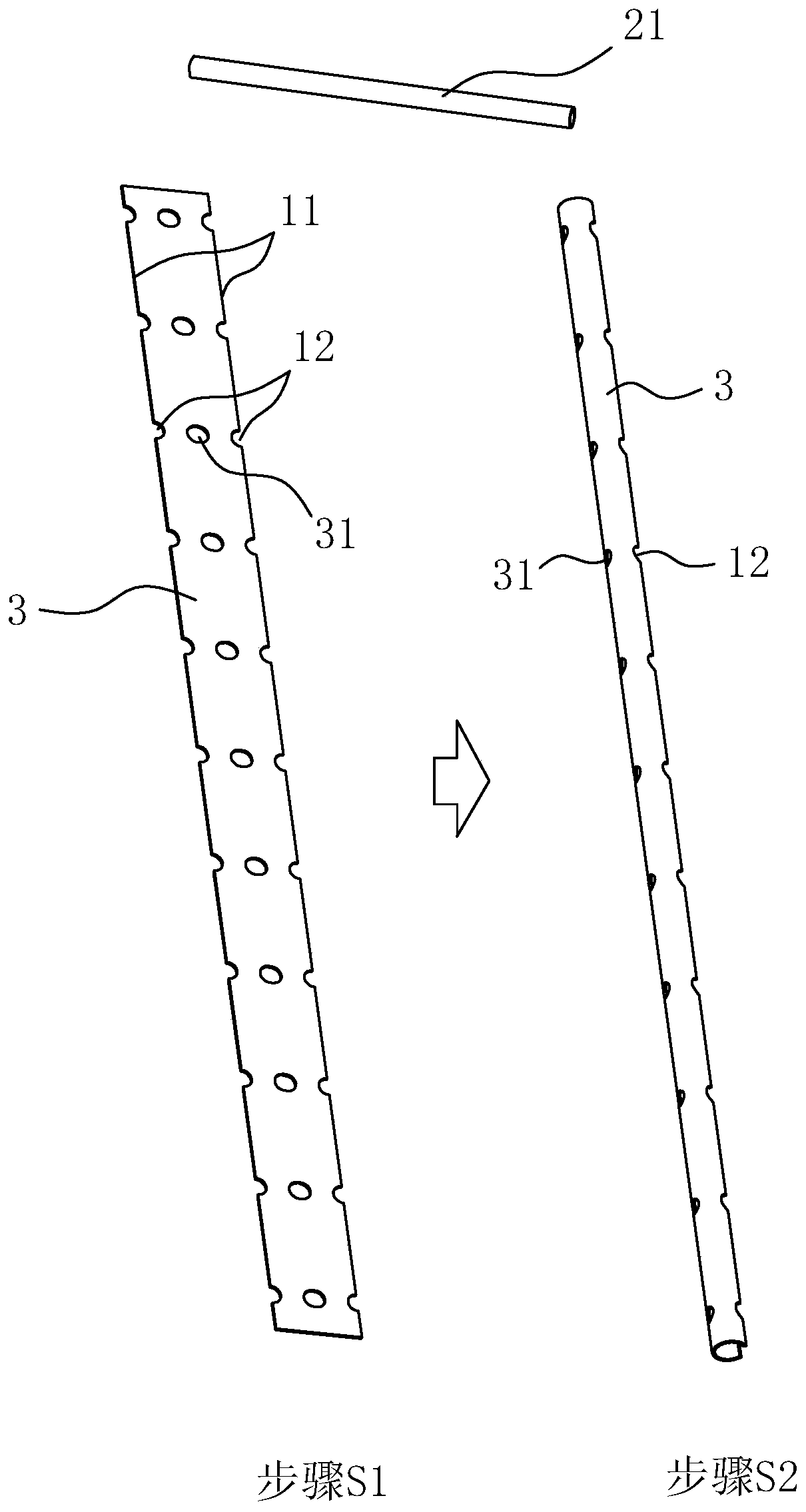

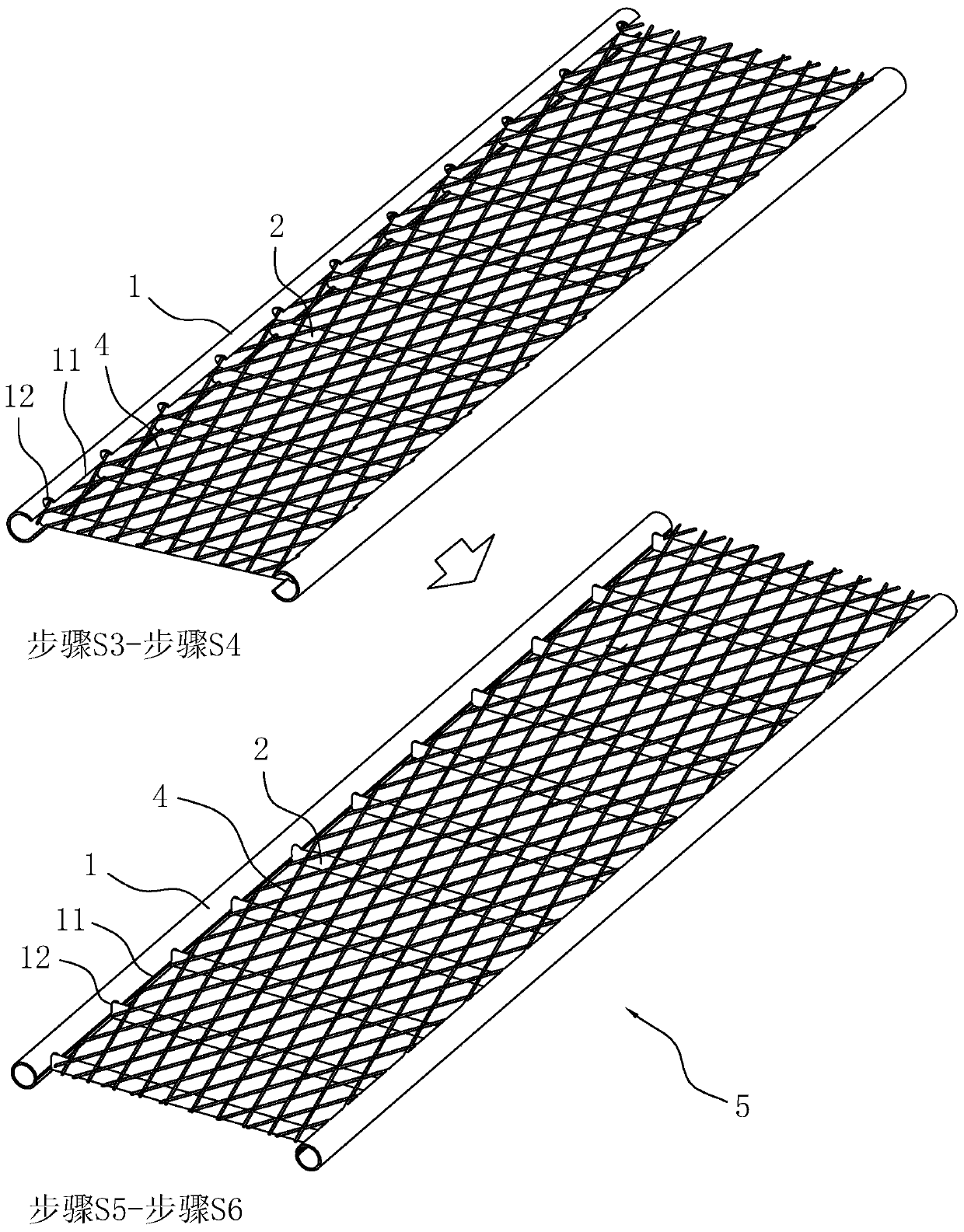

[0042] The invention discloses a production process of a scaffold, comprising the following steps:

[0043] Step S1: Refer to figure 1 and figure 2 , Get a plurality of cross bars 2, steel plates as raw materials. The cross bars 2 are circular steel pipes, and the size and length of each cross bar 2 are the same, and part of the cross bars 2 are taken as the ladder bars 21 . Cutting or punching out the blank 1 on the steel plate, if the cutting method is adopted, it is implemented with a numerical control laser cutting machine, and if the stamping method is adopted, it is implemented with a punching machine. The blank 1 is a strip-shaped plate. The two sides facing away from the width of the blank 1 are closed sides 11, and notches 12 are arranged at intervals on the closed sides 11. The distance between adjacent notches 12 is the same, and the notches 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com