Lithium ion secondary cell

A secondary battery and lithium-ion technology, applied in secondary batteries, lithium batteries, battery electrodes, etc., can solve the problems of large space occupied by current collector fixtures, reduce battery internal resistance, large contact resistance, etc., and achieve excellent cycle characteristics, The effect of high impact resistance and high connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

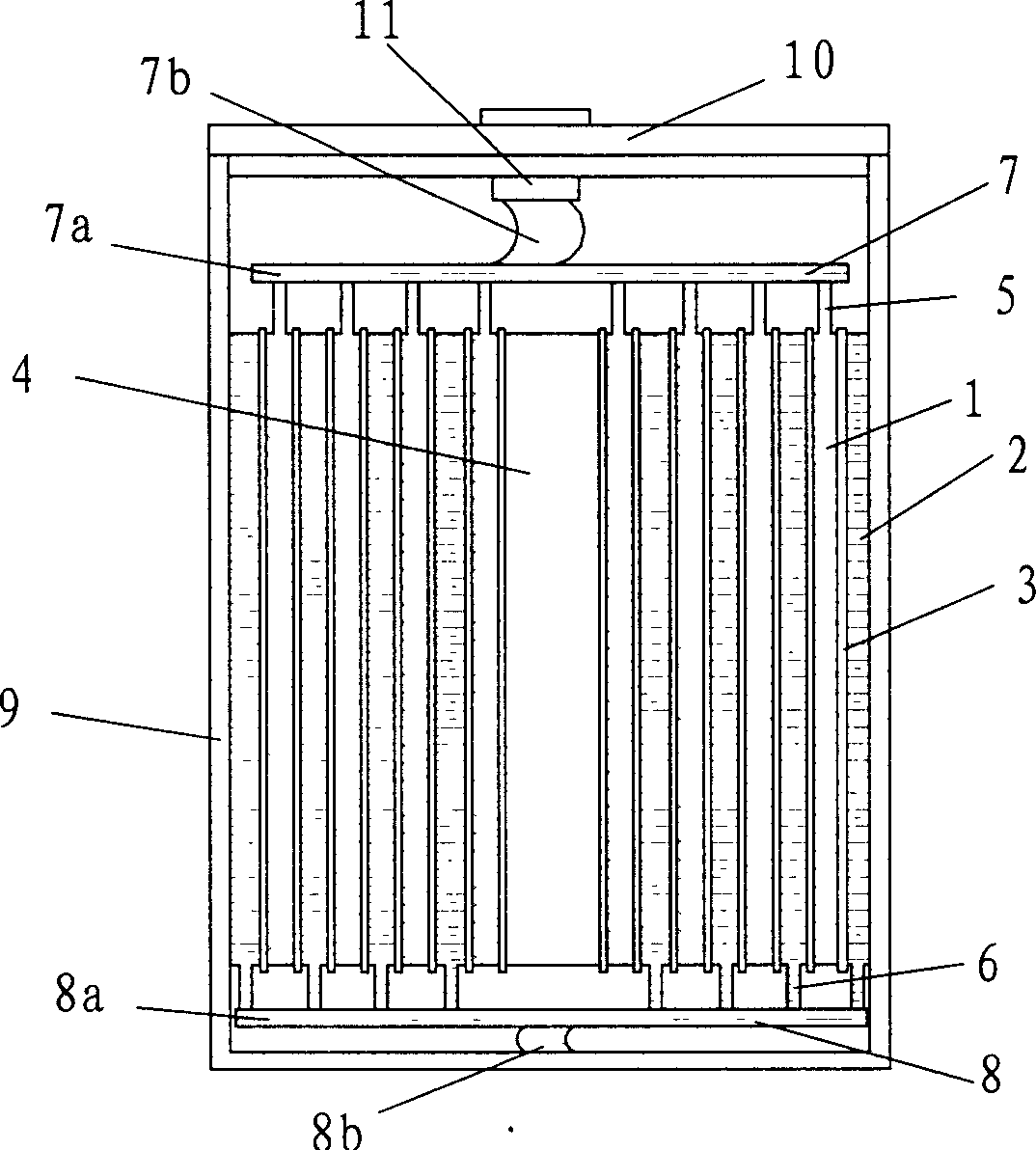

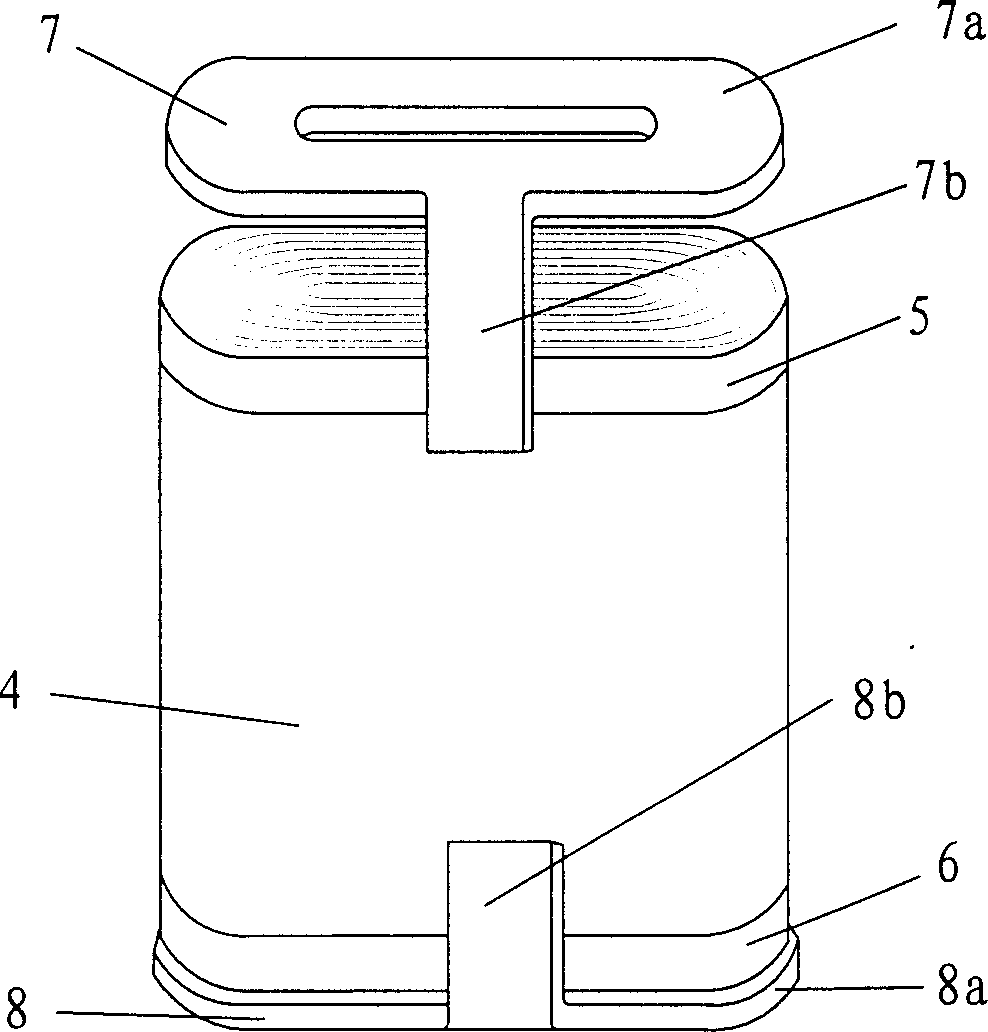

Embodiment 1

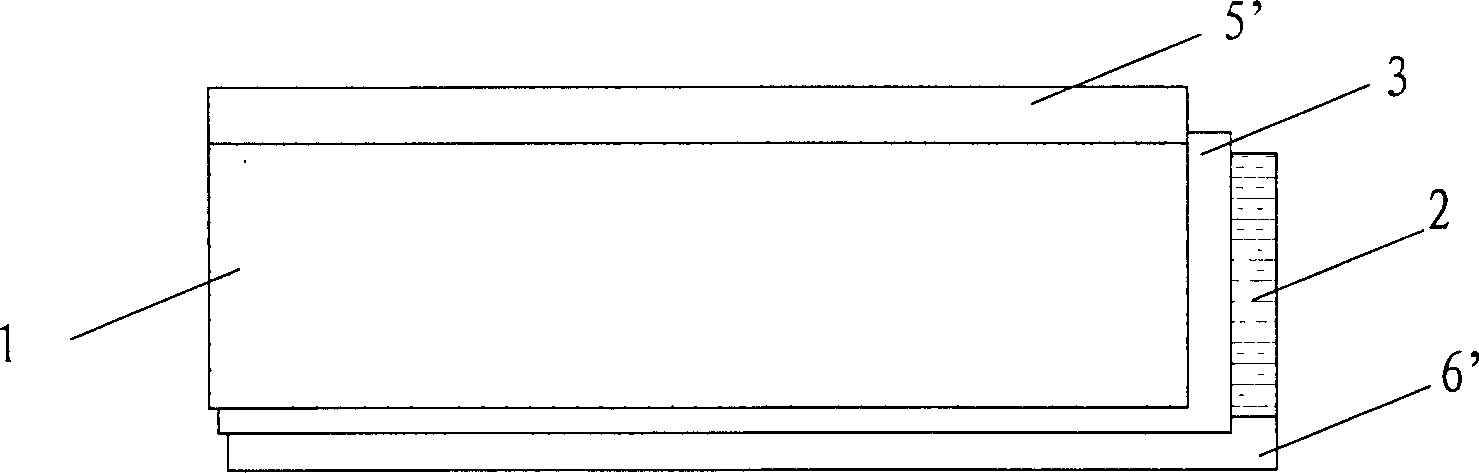

[0029]Positive sheet production: Dissolve a certain amount of PVDF in NMP at a certain ratio, add LiCoO2 and acetylene black to the solution, mix thoroughly to make a slurry, and its composition is LiCoO2: acetylene black: PVDF=92:4:4. This slurry was uniformly coated on a 20 μm aluminum foil, and dried at 120° C. After calendering, a positive electrode sheet with a thickness of 120 μm was obtained. The dressing layer on the edge of the positive electrode sheet was scraped off again to expose the aluminum foil with a width of 10mm.

[0030] Negative sheet production: Dissolve a certain amount of PVDF in NMP at a certain ratio, add artificial graphite into the solution, mix thoroughly to form a slurry, and its composition is artificial graphite:PVDF=95:5. Furthermore, this slurry was uniformly coated on the copper foil of 20 micrometers, and it dried at 120 degreeC. After calendering, a negative electrode sheet with a thickness of 120 μm was obtained. Then the coating layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com