Corrosion inhibitor

A corrosion inhibitor and weight percentage technology, applied in the chemical field, can solve problems such as high cost, pollute the environment, and large dosage of corrosion inhibitor, and achieve the effect of low toxicity, low phosphorus content, and enhanced corrosion inhibition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] This example uses 20# carbon steel, red copper, stainless steel hanging piece (Type I, surface area 28CM 2 ) for corrosion testing.

[0014] Corrosion inhibitor ratio: sodium nitrite 22.7%, sodium borate 2%, HPAA 2%, TEA 2%, BTA 0.3%, acrylic acid sulfonic acid terpolymer 1.5%, NaOH 4%, H 2 O 65.5%.

[0015] Test water quality: PH6.8, conductivity 56us / cm, M-alkalinity (as CaCO 3 Total) 87mg / L, Ca 2+ (as CaCO 3 meter) 0.5mg / L, total hardness (as CaCO 3 Total) 0.8mg / L, Cl-7mg / L.

[0016] Referring to the GB18175-2000 standard, the above corrosion inhibitor and water quality were used to carry out the corrosion test of the rotating coupon. The test water temperature was 45°C, the speed was 75r / min, and the operation was 72h. The amount of corrosion inhibitor added was 400mg / L. The corrosion rate is 0.024mm / a, the corrosion rate of copper coupon is 0.0004mm / a, and the corrosion rate of stainless steel coupon is 0.0001mm / a.

Embodiment 2

[0018] This embodiment is applied in a closed system of softened water in steelmaking, through 20# carbon steel, brass hanging piece (II type, surface area 20CM 2 ) for daily effect monitoring.

[0019] Proportion of corrosion inhibitor: sodium nitrite 22%, sodium borate 2%, HPAA 3%, TEA 2%, BTA 0.3%, acrylic acid sulfonic acid terpolymer 2%, NaOH 4%, H 2 O 64.7%.

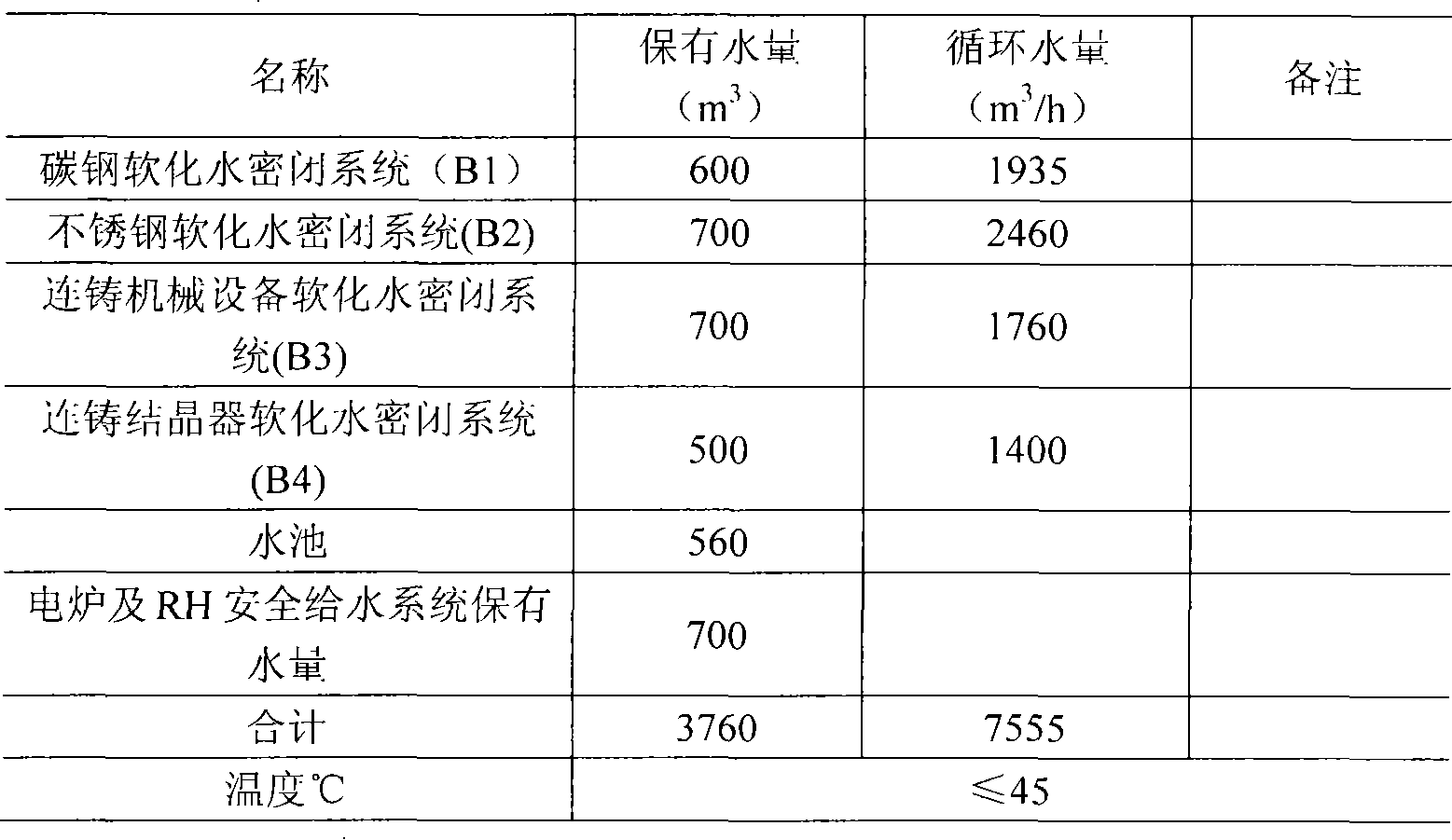

[0020] System parameters:

[0021]

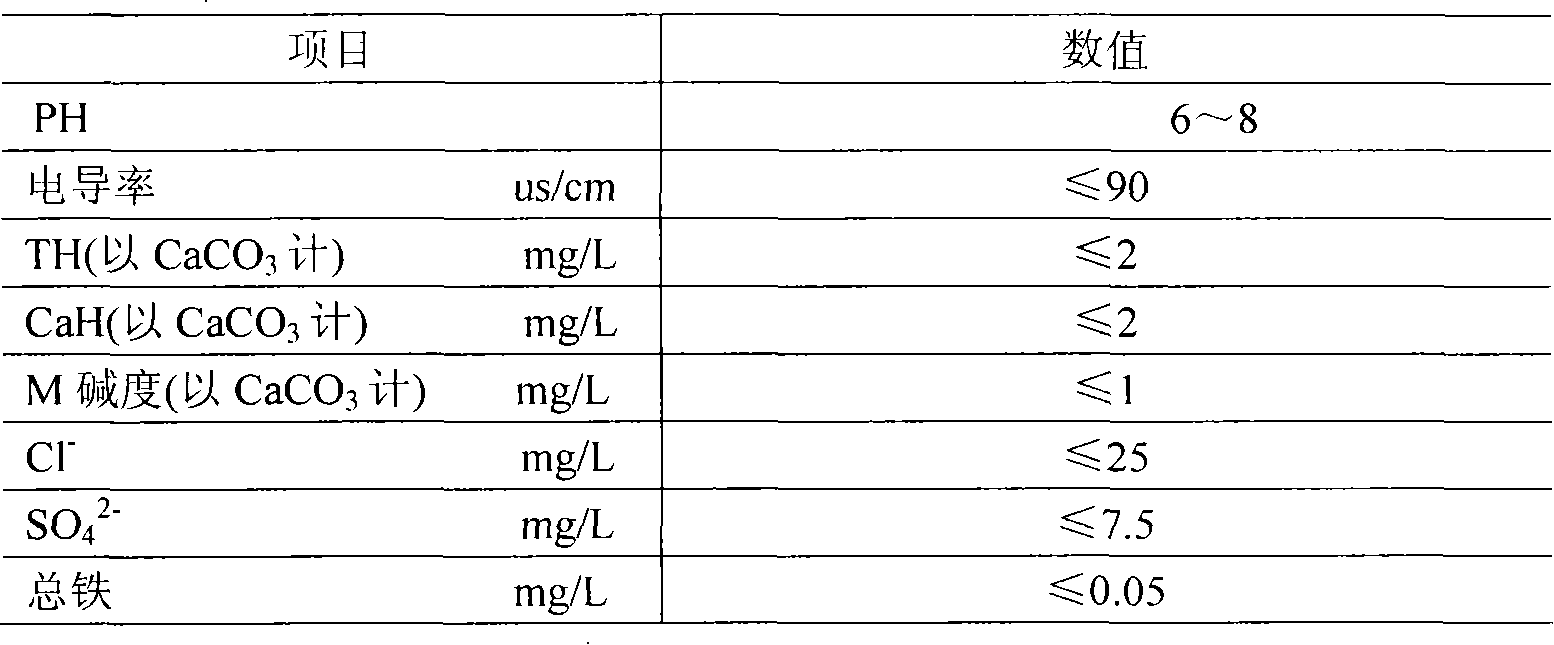

[0022] Supplementary water quality:

[0023]

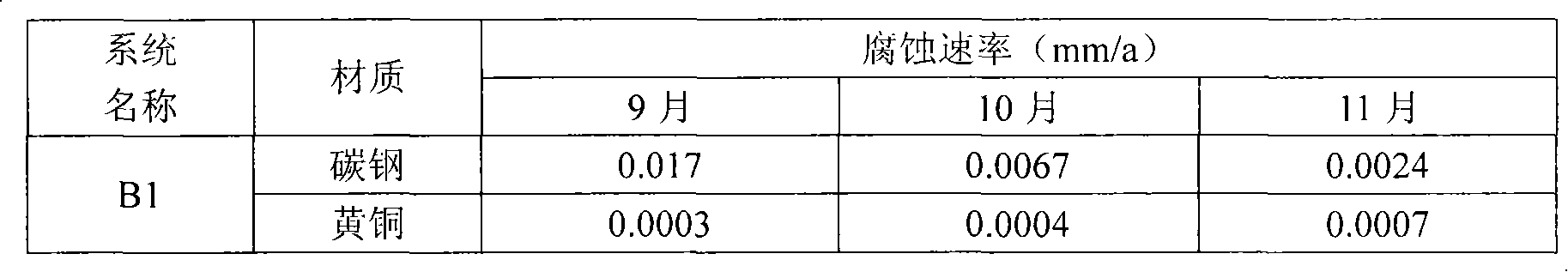

[0024] Add 400mg / L of corrosion inhibitor to the system under the above working conditions and water quality conditions, and hang 20# carbon steel and brass hangers in the hanger boxes set up in the four subsystems (B1, B2, B3, B4) respectively. From September to November 2006, the on-site monitoring coupons were treated monthly according to the coupon treatment method in the GB18175-2000 standard. The corrosion rate is as follows:

[0025]

[0026]

[0027] According to the monitoring data, the corrosion inhibition ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Total hardness | aaaaa | aaaaa |

| Alkalinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com