Neutralizing corrosion inhibitor used in petroleum processing and preparation method thereof

A processing and gentle technology, applied in the petroleum industry, processing equipment corrosion/scaling inhibition, hydrocarbon oil treatment, etc., can solve the problems of odor pollution, instability, strong alkalinity and corrosion inhibitors in the operating environment, etc., and achieve improvement Corrosion inhibition effect, corrosion reduction, safe and convenient production and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

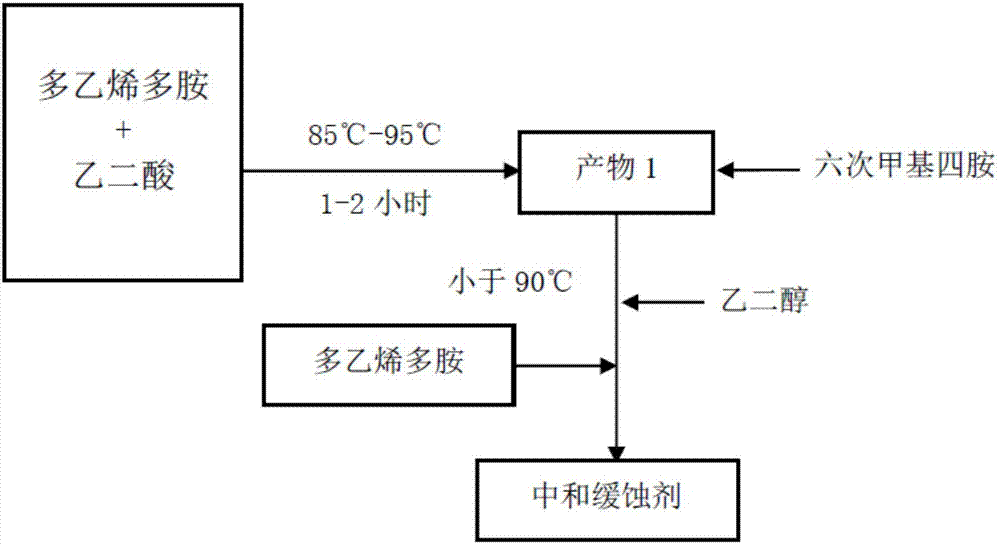

[0035] Such as figure 1 As shown, the present invention provides a method for preparing a neutralizing corrosion inhibitor used in petroleum processing, including: mixing polyethylene polyamine with oxalic acid, and reacting for 1-2 hours at a temperature of 85-95°C After the reflux is condensed, and the pH is controlled to be 6.5-7.5, after the reaction is completed, it is compounded with hexamethylenetetramine, then adjust the freezing point to less than -20℃, and finally adjust the pH value to 11-12 to obtain neutralization and corrosion inhibition Agent.

[0036] The invention synthesizes a polyamine-based corrosion inhibitor by reacting polyethylene polyamine and oxalic acid, and is compounded with hexamethylenetetramine to further improve the corrosion inhibition effect, and then adjust the pH value to improve the product’s resistance to acidic corrosion media Neutralization ability, the neutralization and corrosion inhibition rate of this product in 1% hydrochloric acid so...

Embodiment 1

[0045] A preparation method of a neutralizing corrosion inhibitor used in petroleum processing, including the following steps: Polyethylene polyamine is used as the main raw material, reacted with oxalic acid, and the ratio of polyethylene polyamine and oxalic acid is 2: 1. Under the condition of heating to 85°C, react for 1 hour, condense and reflux, and control the pH to 6.5. After the reaction is completed, add 5% hexamethylenetetramine, cool naturally until the temperature is below 90°C, then add 4% Ethylene glycol and polyethylene polyamine adjust the freezing point to be less than -20°C, and then add 12% of the polyethylene polyamine pH to 11 to obtain the final neutralized corrosion inhibitor product, wherein all percentages are mass percentages.

[0046] The main performance indicators of the neutralizing corrosion inhibitor used in the petroleum processing process provided by the present invention are shown in Table 1:

[0047] project

[0048] (Table I)

Embodiment 2

[0050] A preparation method of a neutralizing corrosion inhibitor used in petroleum processing, including the following steps: Polyethylene polyamine is used as the main raw material, reacted with oxalic acid, and the ratio of polyethylene polyamine and oxalic acid is 2: 1. Under the condition of heating to 90℃, react for 1.5 hours, condense and reflux, and control the pH to 7.0. After the reaction is completed, add 6% of hexamethylenetetramine, and cool naturally until the temperature is below 90℃, then add 5.5% Adjust the freezing point of ethylene glycol and polyvinyl polyamine to be less than -20°C, and then add 13.5% of polyvinyl polyamine to a pH value of 11-12 to obtain the final neutralized corrosion inhibitor product

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com