Application of carbon steel corrosion inhibitor in transmission and distribution of regenerated water heat supply network

A technology for reclaimed water and corrosion inhibitor, applied in the field of water treatment, can solve the problems of high phosphorus and zinc content, high price, and can not meet the quality requirements of the recycled water at the end of the pipe network, so as to reduce the amount of phosphorus and zinc, improve the corrosion inhibition effect, and reduce corrosion. significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0028] Example 1

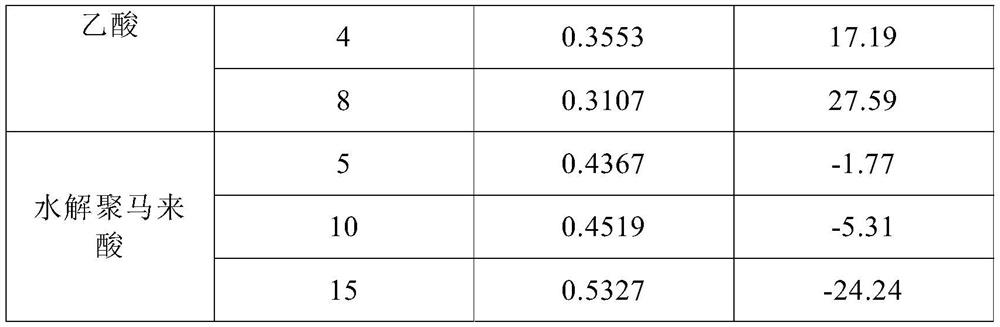

[0029] This example provides a carbon steel corrosion inhibitor in the regenerated hydraulic hot mesh transmission, and the components of the carbon steel corrosion inhibitor are added to the regenerated water by hot mesh, and the mix is mixed into regenerated water, wherein The concentration of the carbon steel corrosion inhibitor and its concentration in regeneration water is as follows: hydrolyzed polymeric acid is 5 mg / L, acrylic acid and 2-acrylamide-2-methylpropulfonic acid copolymer 2 mg / L, Nine hydrated sodium silicate is 15 mg / L, sodium gluconate is 2 mg / L, 2 mg / L of seven water sulfate 2mg / L, 2-hydroxyphosphonic acid 1 mg / L.

Example Embodiment

[0030] Example 2

[0031] This example provides a carbon steel corrosion inhibitor in the regenerated hydraulic hot mesh transmission, and the components of the carbon steel corrosion inhibitor are added to the regenerated water by hot mesh, and the mix is mixed into regenerated water, wherein The carbon steel corrosion inhibitor each and its concentration in regenerated water is as follows: hydrolyzed polymeric acid is 8 mg / L, acrylic acid and 2-acrylamide-2-methylpropulfonic acid copolymer 2 mg / L, Nine hydrated sodium silicate is 10 mg / L, sodium gluconate is 1 mg / L, zinc sulfate 2mg / L, 2-hydroxyphonic acid 1 mg / L.

Example Embodiment

[0032] Example 3

[0033] This example provides a carbon steel corrosion inhibitor in the regenerated hydraulic hot mesh transmission, and the components of the carbon steel corrosion inhibitor are added to the regenerated water by hot mesh, and the mix is mixed into regenerated water, wherein The concentration of the carbon steel corrosion inhibitor and its concentration in regenerated water is as follows: hydrolyzed polymeric acid is 4 mg / L, acrylic acid and 2-acrylamide-2-methylpropulfonic acid copolymer 1 mg / L, Nine hydrated sodium silicate is 15 mg / L, sodium gluconate is 4 mg / L, zinc sulfate 3mg / L, 2-hydroxyphosphonic acid 2 mg / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com