Low phosphorus lubricating oil composition having lead corrosion control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

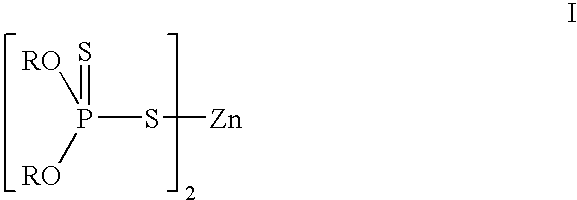

[0072]The low phosphorus lubricating oil composition of the present invention was prepared by blending a 0.78 wt % mixture of zinc bis(O,O′-di-(2-ethyl-1-hexyl) dithiophosphate (0.24 wt %, primary), zinc bis(O,O′-di-(2-butyl / 4-methyl-2-pentyl) dithiophosphate (0.15 wt %, secondary) and zinc bis(O,O′-di-(dodecylphenyl) dithiophosphate (0.39 wt %, aryl) with a Group II base oil of lubricating viscosity. The ratio of zinc bis(O,O′-di-(2-ethyl-1-hexyl) dithiophosphate to zinc bis(O,O′-di-(2-butyl / 4-methyl-2-pentyl) dithiophosphate was about 1:1, based on the phosphorus content. The ratio of the mixture of zinc bis(O,O′-di-(2-ethyl-1-hexyl) dithiophosphate and zinc bis(O,O′-di-(2-butyl / 4-methyl-2-pentyl)dithiophosphate to zinc bis(O,O′-di-(dodecylphenyl) dithiophosphate was about 2:1, based on the phosphorus content. The resulting ratio of the three-way mixture of zinc bis(O,O′-di-(2-ethyl-1-hexyl) dithiophosphate to zinc bis(O,O′-di-(2-butyl / 4-methyl-2phenyl) dithiophosphate to zinc bis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com