Method for treating wastewater of azo dye

A technology for wastewater treatment and azo dyes, which is used in energy wastewater treatment, light water/sewage treatment, mechanical oscillation water/sewage treatment, etc. The effect of large-scale application and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

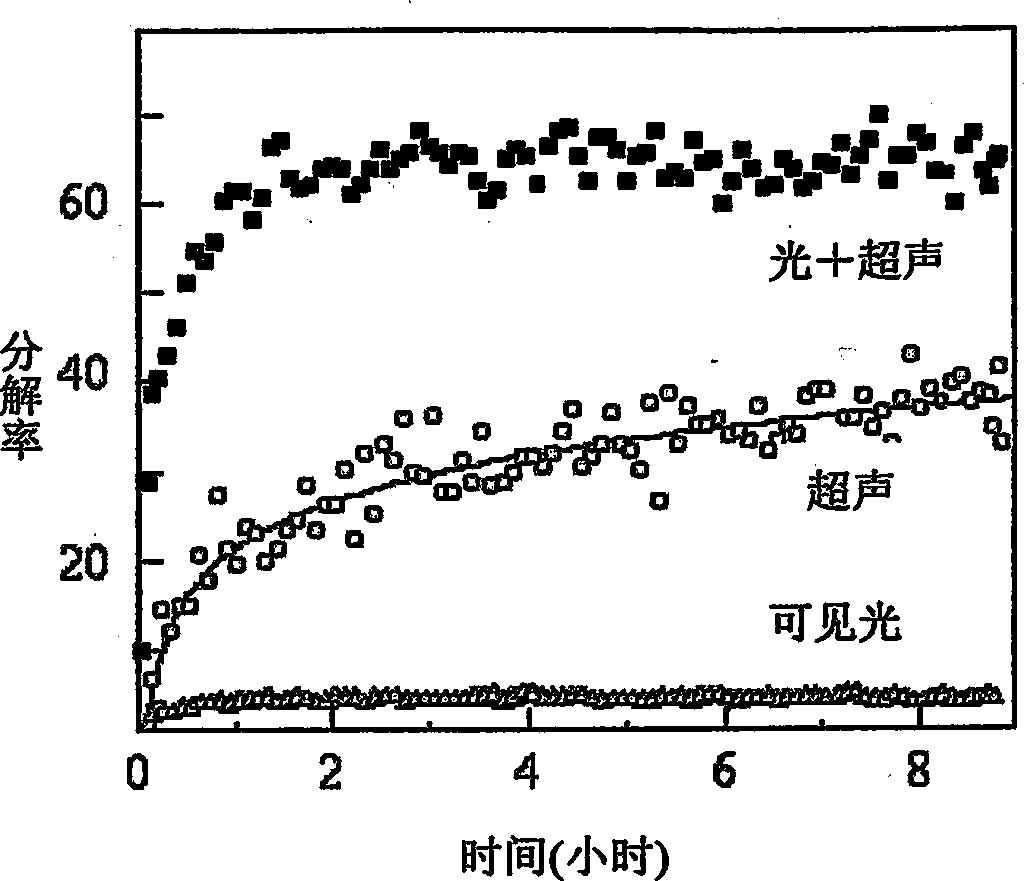

[0026] Embodiment 1: This embodiment comprises the following steps:

[0027] (1) At room temperature, the concentration was 1.43×10 -4 The Acid Orange II wastewater solution of mol / L is put into the treatment tank, wherein Acid Orange II is a typical azo dye;

[0028] (2) The frequency of the ultrasonic wave generated by the ultrasonic generating device adopted is 1MHz, the electric power of the transducer is 40W, and the irradiation mode is irradiation from the bottom of the waste water treatment pool;

[0029] (3) A xenon lamp (0-300W) is used as a visible light source, and the average irradiated light power is 7.64mW / cm 2 , the irradiation method is that the light source is irradiated from the top of the treatment pool to the bottom;

[0030] (4) Simultaneously open the ultrasonic generating device and the visible light source, and jointly irradiate the azo dye wastewater with ultrasonic and light;

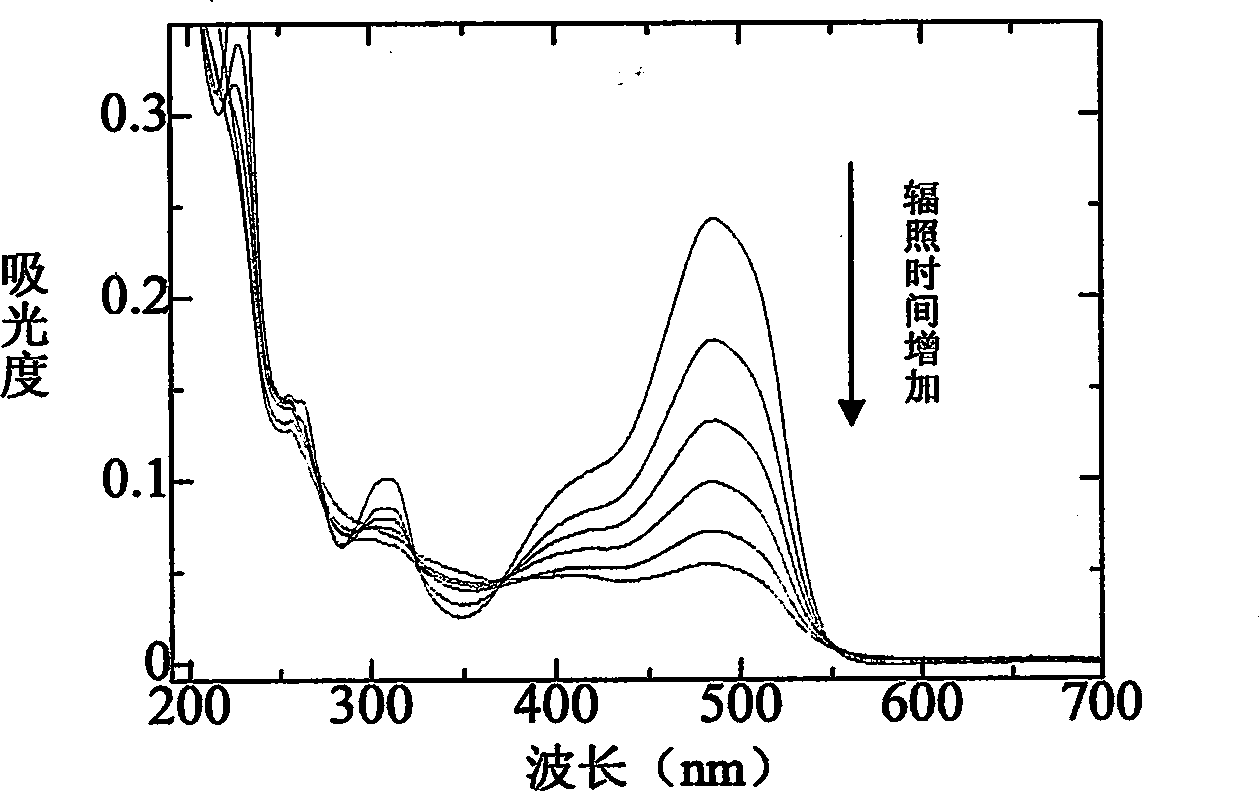

[0031] (5) Detect the decomposition result of the dye while treating th...

Embodiment 2

[0034] Embodiment 2: In this embodiment, two 20KHz, 150W ultrasonic transducers are used as ultrasonic sources instead of the ultrasonic transducers in Embodiment 1, and the irradiation method adopts the method of inserting the ultrasonic transducer tool head into the wastewater solution. Carry out the same steps in embodiment 1, obtain the result consistent with example 1.

Embodiment 3

[0035] Embodiment 3: A 20KHz, 150W ultrasonic transducer and a 1MHz, 40W ultrasonic transducer are used as the ultrasonic radiation source. The 20KHz ultrasonic transducer is irradiated by immersing the tool head in the wastewater solution, and the 1MHz, 40W ultrasonic transducer is irradiated from the bottom of the wastewater pool; the visible light source is combined with two xenon lamps with different irradiating light powers, one of which is The irradiation method adopts the irradiation method from the top to the bottom of the treatment pool, and the average irradiation light power is 7.64mW / cm 2 , another xenon lamp irradiation method is to irradiate from the side of the treatment pool to the solution, and the average irradiated light power is 3.80mW / cm 2. Carry out the same steps in embodiment 1, obtain the result consistent with example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com