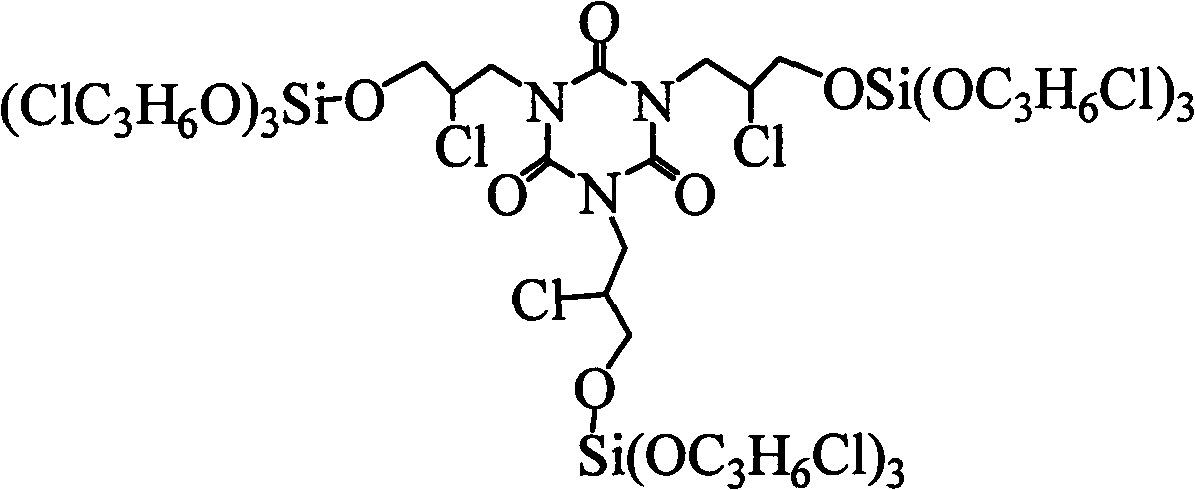

Triazinetri-tri(chloropropyl) silicate compound and preparation method thereof

A technology of triazine trisilicate tri-ester compound, which is applied in the field of flame retardant plasticizer, can solve the problems of long non-halogenation of flame retardants, and the process of non-halogenation will not be too fast, and achieve stable molecular structure and good environment. Benefit, good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

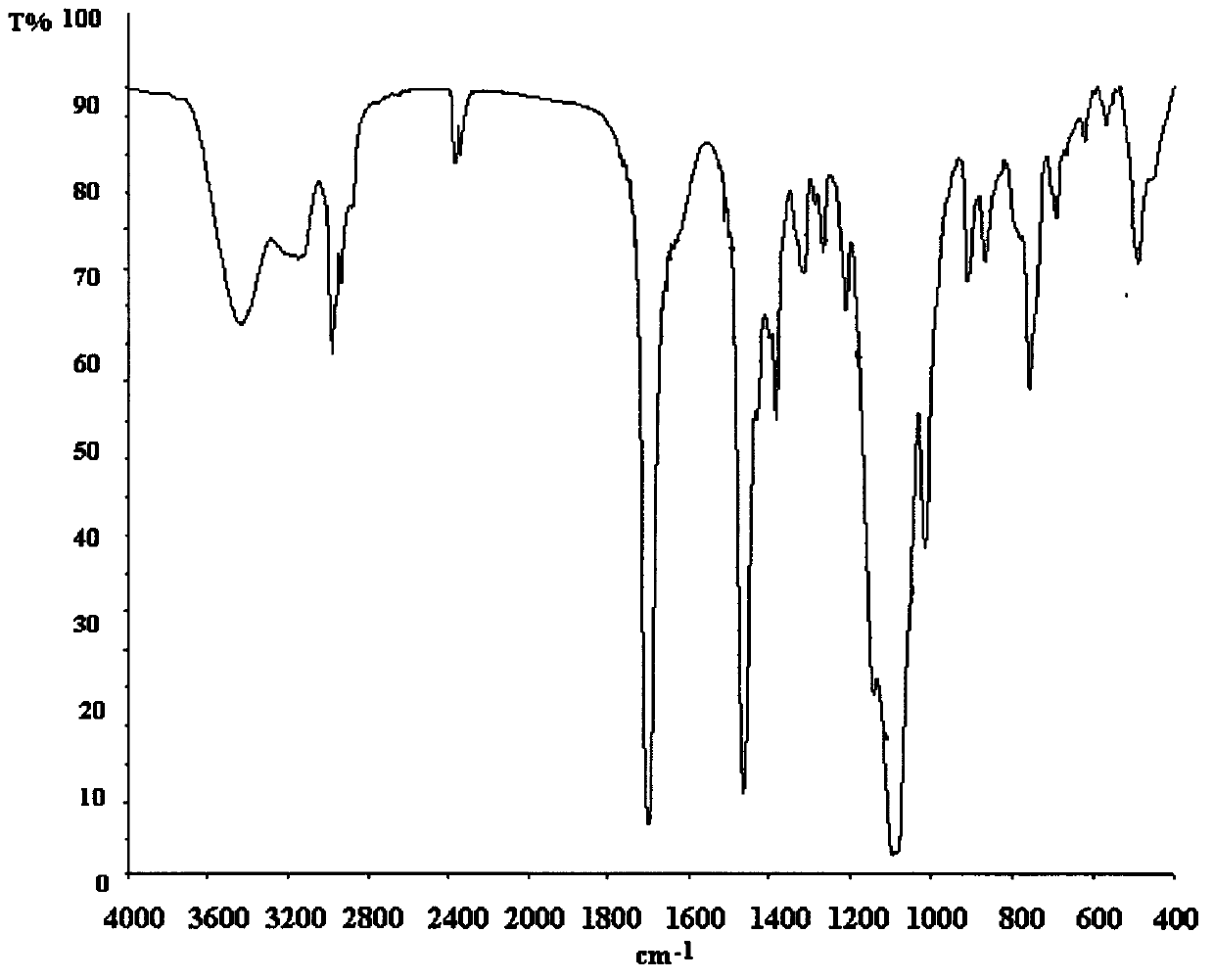

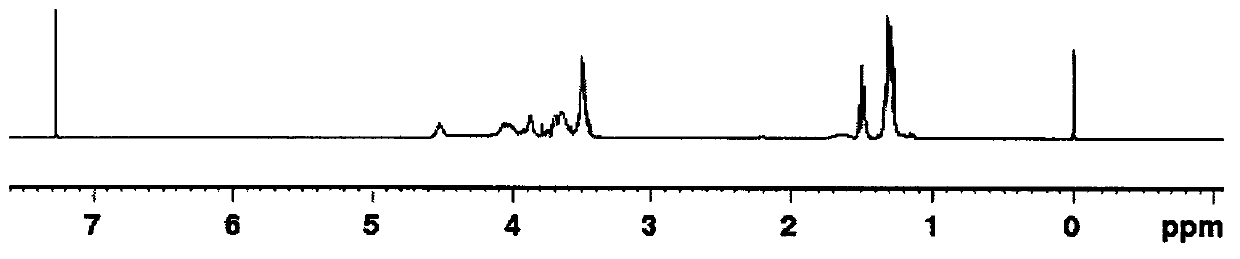

Image

Examples

Embodiment 1

[0029] Example 1 In a 100mL three-neck flask equipped with a stirrer, a thermometer and a high-efficiency reflux condenser, add 10ml of acetonitrile, 3.40ml of SiCl 4 (0.03 mol). Dissolve 3.00g (0.01mol) triglycidyl isocyanurate in 50ml of acetonitrile, drop it into a three-necked flask at 25°C, control the reaction temperature not higher than 30°C during the dropping process, and complete the dropwise addition After that, heat up to 60°C for 1h and keep it warm for 4h; lower the reaction system to 30°C, add 11.61g (0.09mol) 2-chloropropanol dropwise, and control the reaction temperature to not exceed 40°C at the rate of addition. Raise the temperature of the system to 60°C and keep it warm for 6 hours, add about 0.5g of triethylamine, adjust to PH = 5-6, stir for 1 hour, filter, distill off the organic solvent from the filtrate (for recycling), and distill out a small amount of low boiling point substances under reduced pressure , to get three {2-chloro-3-[three (2-chloropro...

Embodiment 2

[0030] Example 2 In a 100mL three-neck flask equipped with a stirrer, a thermometer and a high-efficiency reflux condenser, add 10ml of dichloroethane, 3.40ml of SiCl 4(0.03mol), 3.00g (0.01mol) of triglycidyl isocyanurate was dissolved in 50ml of dichloroethane, and at 25°C, it was dropped into the three-necked bottle, and the dropping process controlled the reaction temperature to If the temperature is higher than 30°C, after the dropwise addition is completed, heat up to 60°C for 1h and keep the temperature for 6h; lower the reaction system to 30°C, add 12.26g (0.095mol) 2-chloropropanol dropwise, and control the reaction temperature by the rate of addition to not exceed 4 ℃, after the dropwise addition, raise the temperature of the system to 60℃ and keep it warm for 6h, add about 0.5g N,N-dimethylaniline, adjust to PH=5-6, stir for 1h, filter, and distill the filtrate to remove the organic solvent and Excess 2-chloropropanol (recycled for use), and then evaporate a small a...

Embodiment 3

[0031] Example 3 In a 100mL three-neck flask equipped with a stirrer, a thermometer and a high-efficiency reflux condenser, add 10ml tetrahydrofuran, 3.40ml SiCl 4 (0.03 mol). Dissolve 3.00g (0.01mol) triglycidyl isocyanurate in 50ml tetrahydrofuran, drop it into a three-necked flask at 25°C, control the reaction temperature not higher than 30°C during the dropping process, and complete the dropwise addition After that, heat up to 60°C for 1h and keep the temperature for 5h; lower the reaction system to 30°C, add 12.9g (0.10mol) of 2-chloropropanol dropwise, and control the reaction temperature at a rate of addition not to exceed 40°C. After the dropwise addition, the Raise the temperature of the system to 50°C and keep it warm for 5 hours, add about 0.5g of melamine, adjust to PH=5-6, stir for 1 hour, filter, distill off the organic solvent and excess 2-chloropropanol (recycled) from the filtrate, and then depressurize A small amount of low-boilers were evaporated to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com